Paper material having multiple functions, its manufacturing method and application

A paper material and functional technology, applied in papermaking, roll-resistant paper, textiles and papermaking, etc., can solve problems such as unsatisfactory field cultivation of waste paper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

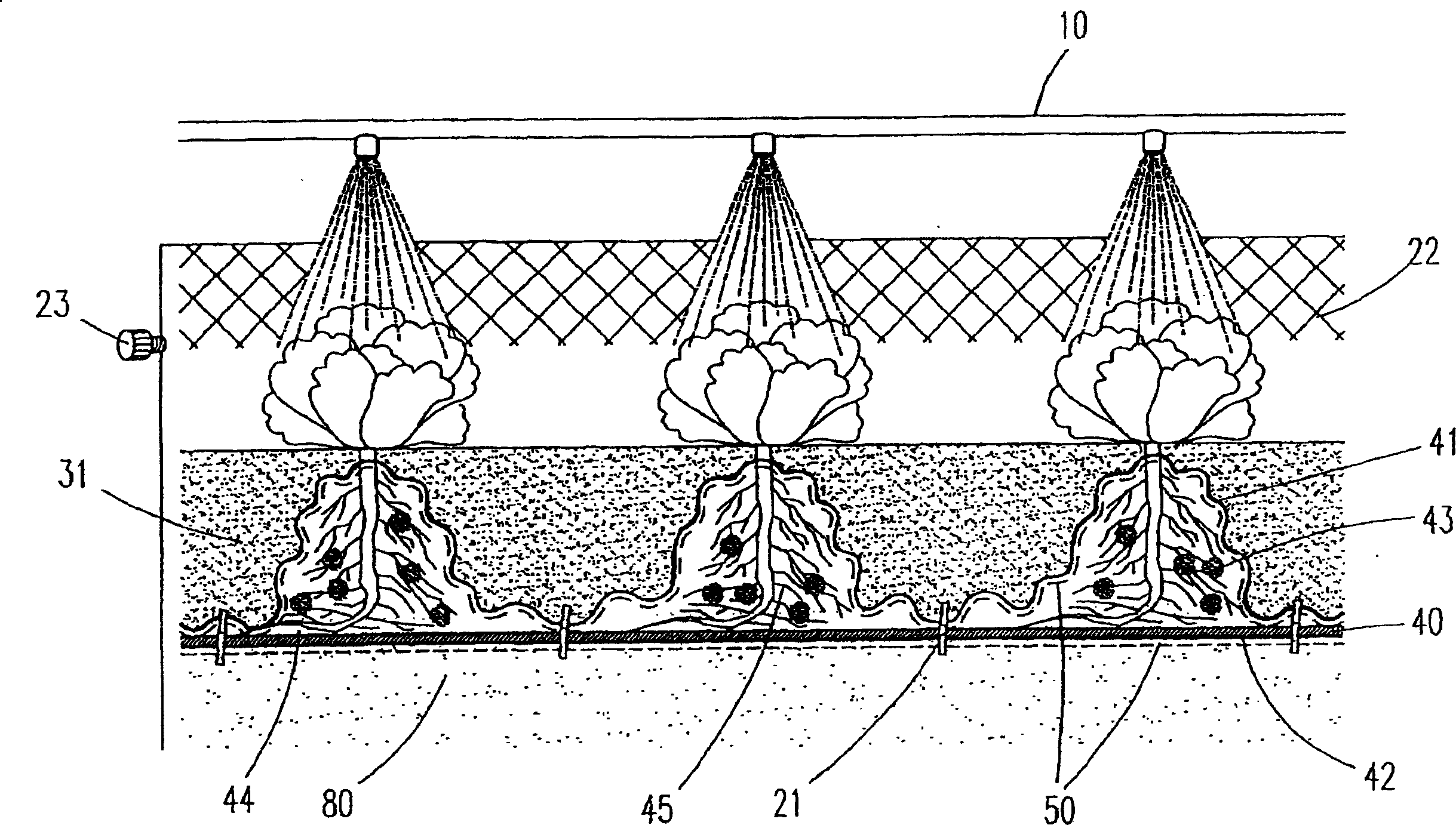

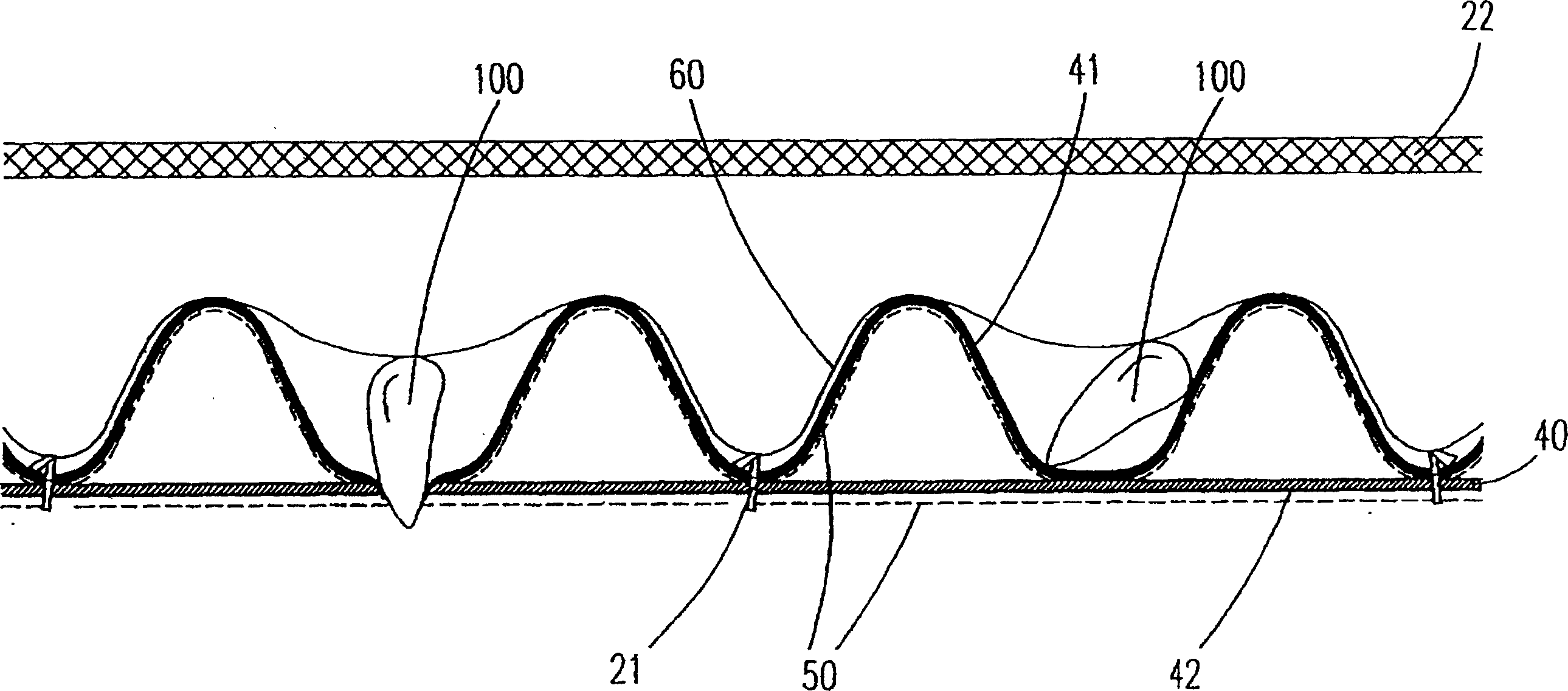

[0023] figure 1 with figure 2 It is a structural schematic diagram of a preferred embodiment of the present invention. Its main components are as follows:

[0024] 1: Generally, corrugated boxes with the backing paper removed (such as image 3 Shown) or on the bottom paper of the carton or its core paper 41 surface spraying anti-disease and insect pest microbial preparation to form the disease and insect pest control microbial preparation coating layer 50, and spraying long-acting fertilizer 43, and the seed wrapping protective agent is pasted on the core paper 41 surface and coated tissue paper material on the seed 100 and die-casting into a seed coating lattice.

[0025] 2: The substrate of surface paper 42 is kraft paper with air permeability, water permeability, high gluing, and high moisture resistance.

[0026] 3: The base material of the core paper 41 is preferably a corrugated structure with low moisture resistance, high water permeability and high (A) corrugation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com