Hydraulic valve mechanism for internal combustion engine

A valve train, engine technology, applied in the direction of engine components, machines/engines, non-mechanically actuated valves, etc., can solve the problems of unable to replace the valve train, large cost-to-target ratio, difficult to achieve goals, etc. The effect of valve noise, improving service life and long full opening time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

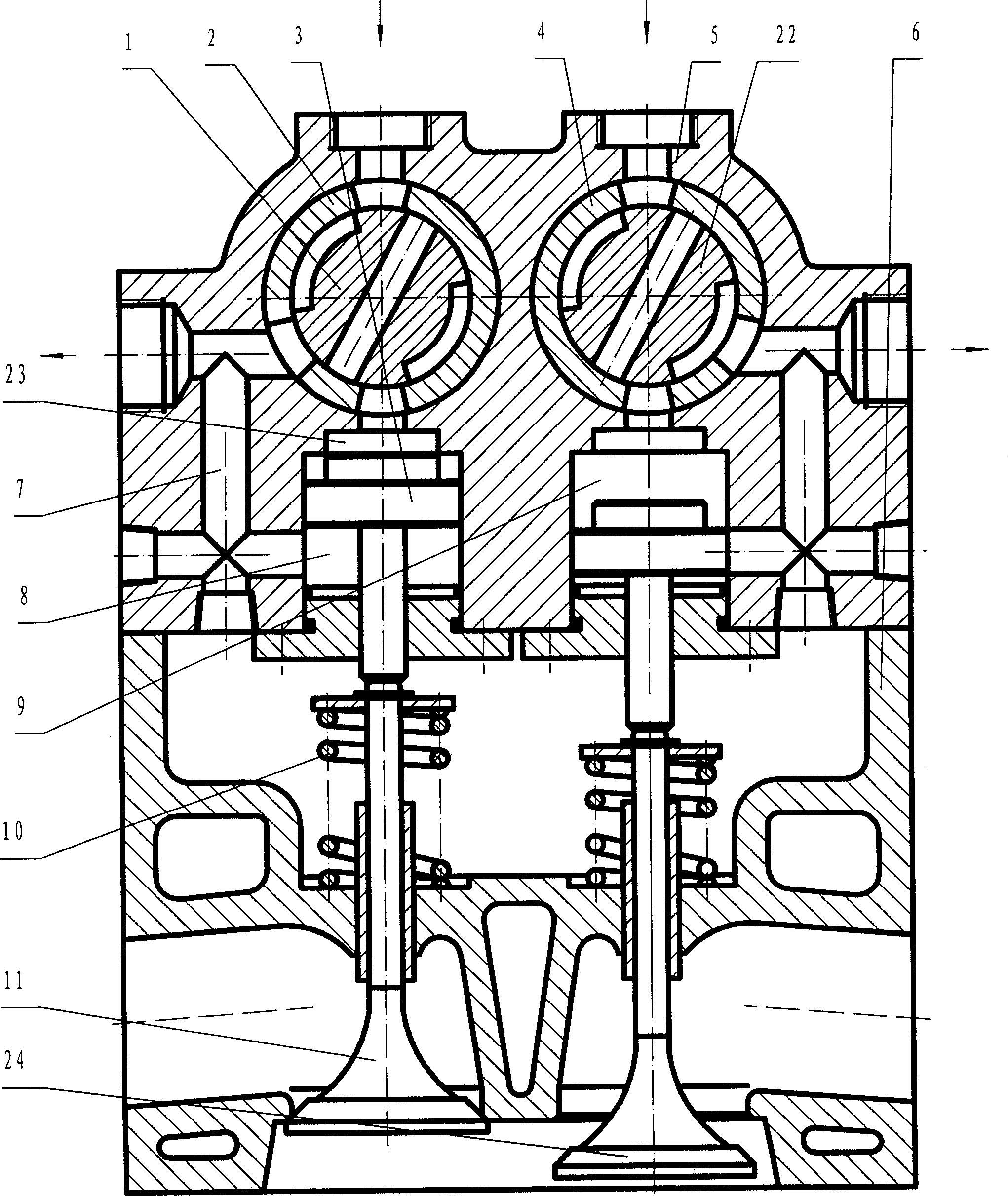

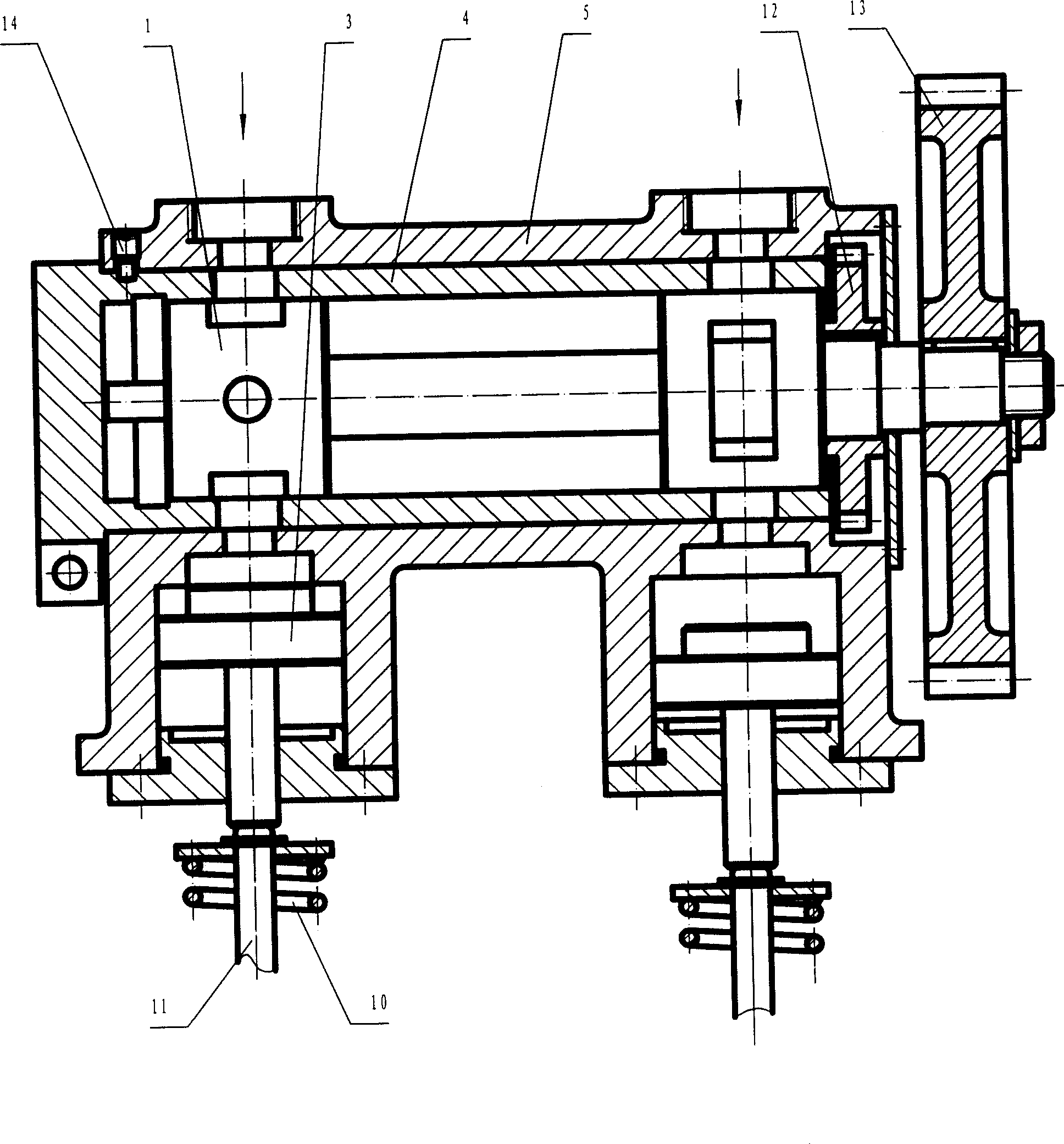

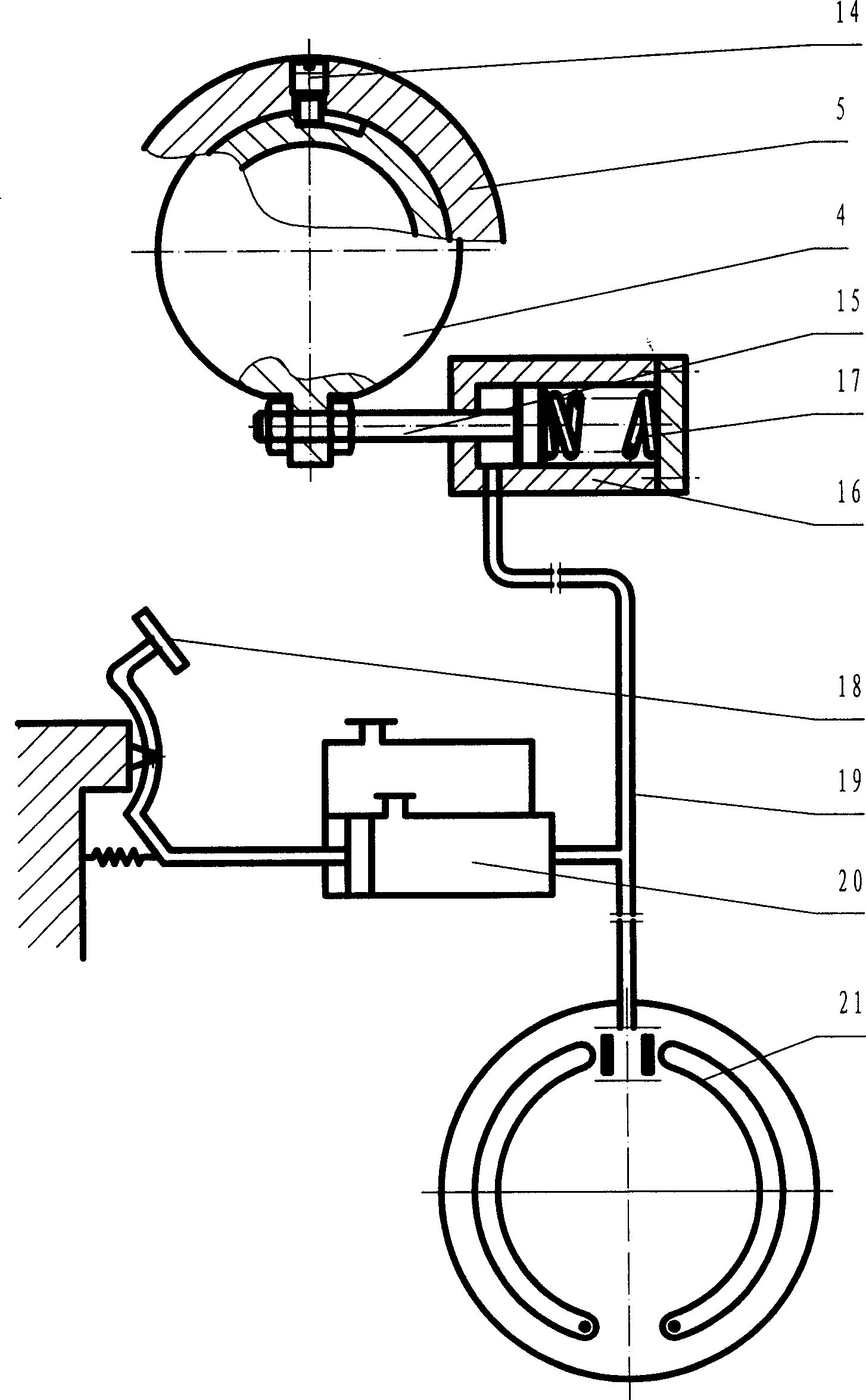

[0011] Such as figure 1 , 2 Shown, the hydraulic valve mechanism of internal-combustion engine of the present invention replaces parts such as camshaft, pushrod, tappet, rocker arm in the prior art with rotary valve, valve sleeve, oil piston. figure 1 Intake valve 11 is shown on the left, and exhaust valve 24 is shown on the right, at the beginning of the intake stroke of the engine cylinder. It includes a gas distribution valve body 5, and an intake valve sleeve 2 and an exhaust valve sleeve 4 are arranged inside the gas distribution valve body 5. Intake valve sleeve 2 and exhaust valve sleeve 4 are provided with intake rotary valve 1 and exhaust rotary valve 22 matched therewith. The intake rotary valve 1 and the exhaust rotary valve 22 are provided with oil inlet and drain passages on the radial section, and are sequentially connected with the oil inlet and drain holes on the valve sleeve. One of the intake and exhaust valve sleeves 2 and 4 is fixed with the gas distribu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com