Method for producting metallic powders consisting of irregular particles

An irregular and granular technology, applied in the field of metal powder, can solve problems such as lack of sintering performance, small powder particle size, inconsistent powder particle size, etc., and achieve the effect of promoting surface area expansion and improving particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

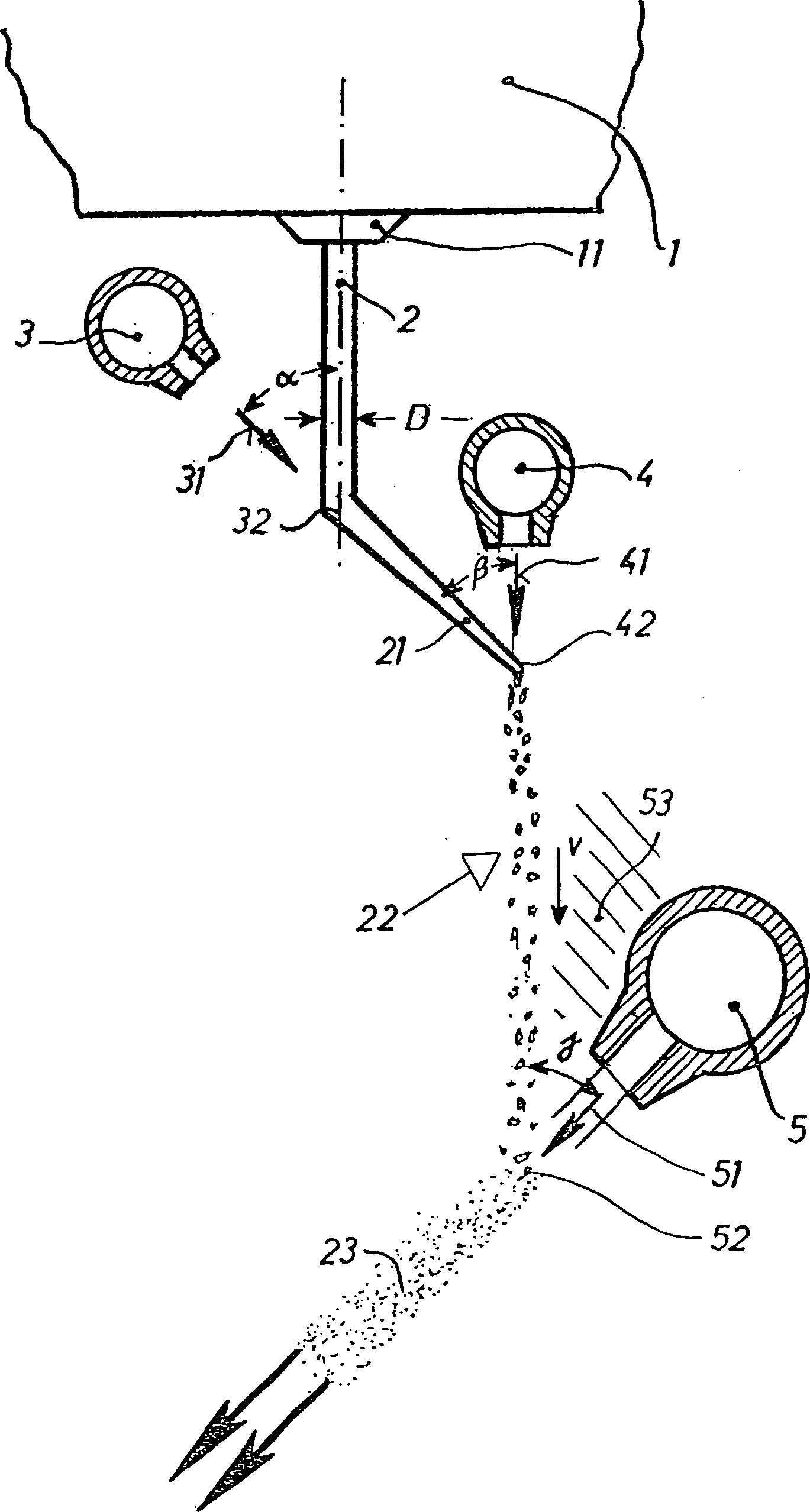

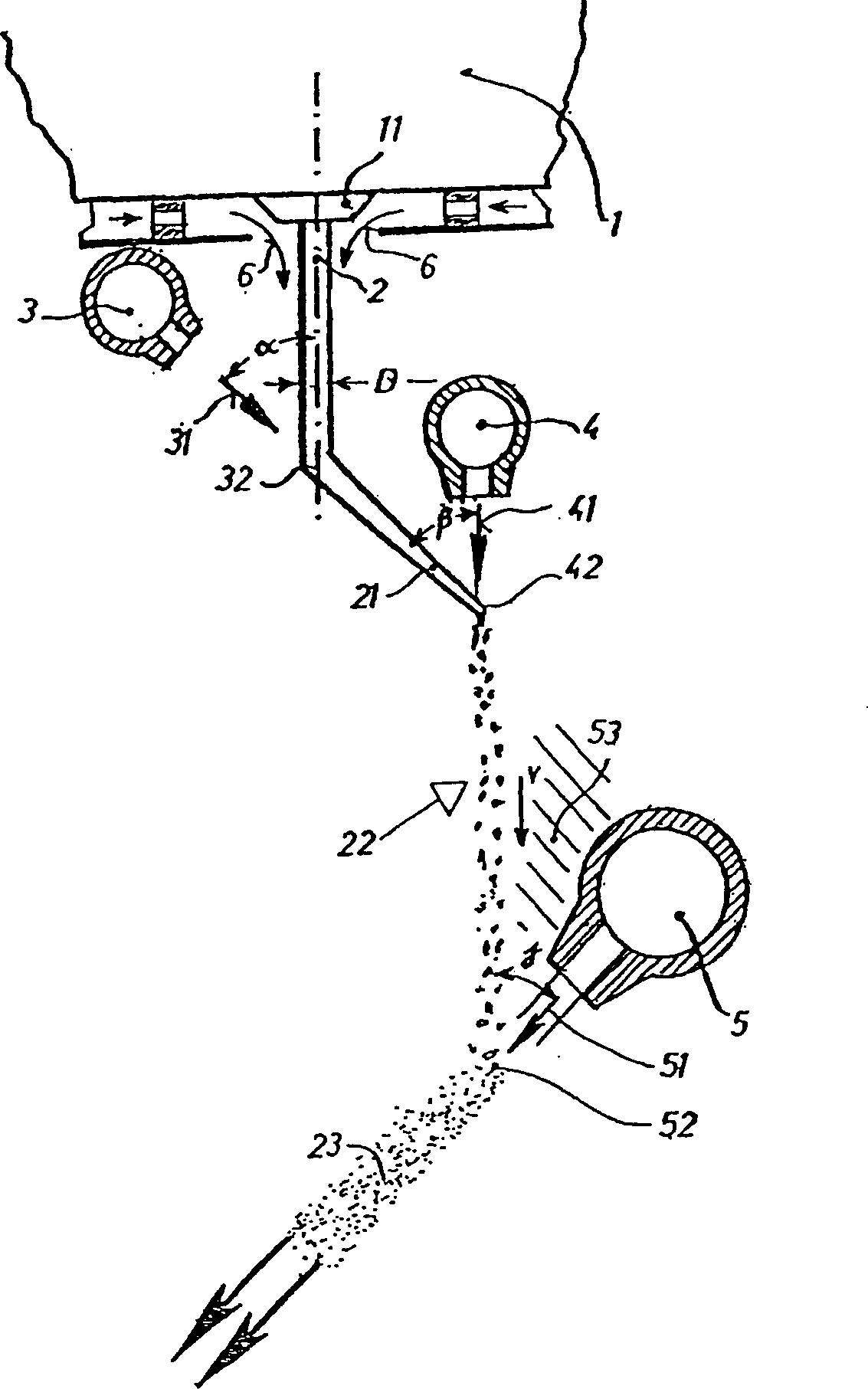

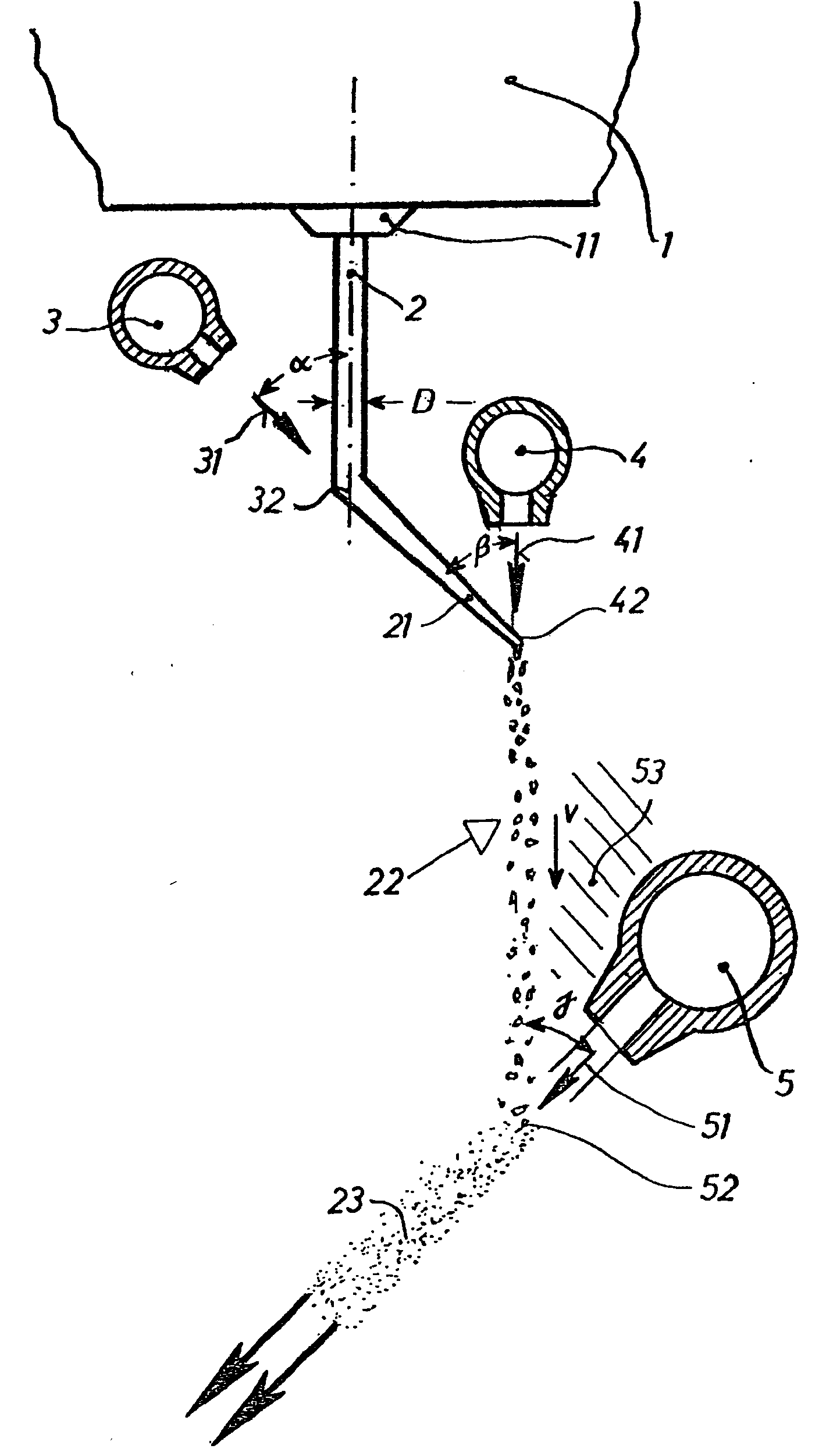

[0032] As in figure 1 As can be seen in the schematic diagram in a metallurgical vessel 1, there is a kind of overheated melt, which flows out of the vessel in the vertical direction through a wind eye brick / nozzle body (Düsenstein) 11, forming a casting stream with a diameter of D 2.

[0033] The device 3, which is advantageously designed as a flat beam nozzle device, is used in a first step at an acute angle α with a deflecting medium 31, such as water, a water-gas mixture or a gas, to act on the vertical casting stream 2, wherein the casting stream 2 In the area 32, it is shot so that its surface area is enlarged and widened.

[0034] The broadened pouring stream 21 that is substantially or still continuously distributed over a large area is then loaded by a loading system 4 with a media stream 41 that is advantageously formed to have a wide shape at an acute angle β. When the pouring stream 21 widened in the second step and the medium stream 41 meet, the pouring stream 21 wid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com