Method of preparing boron-phosphor-silicon fluorine glass

A technology of borophosphosilicate glass and fluoroalkoxysilane, which is applied in the field of making fluorine-doped borophosphosilicate glass, and can solve problems such as the viscosity reduction of dielectric films

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

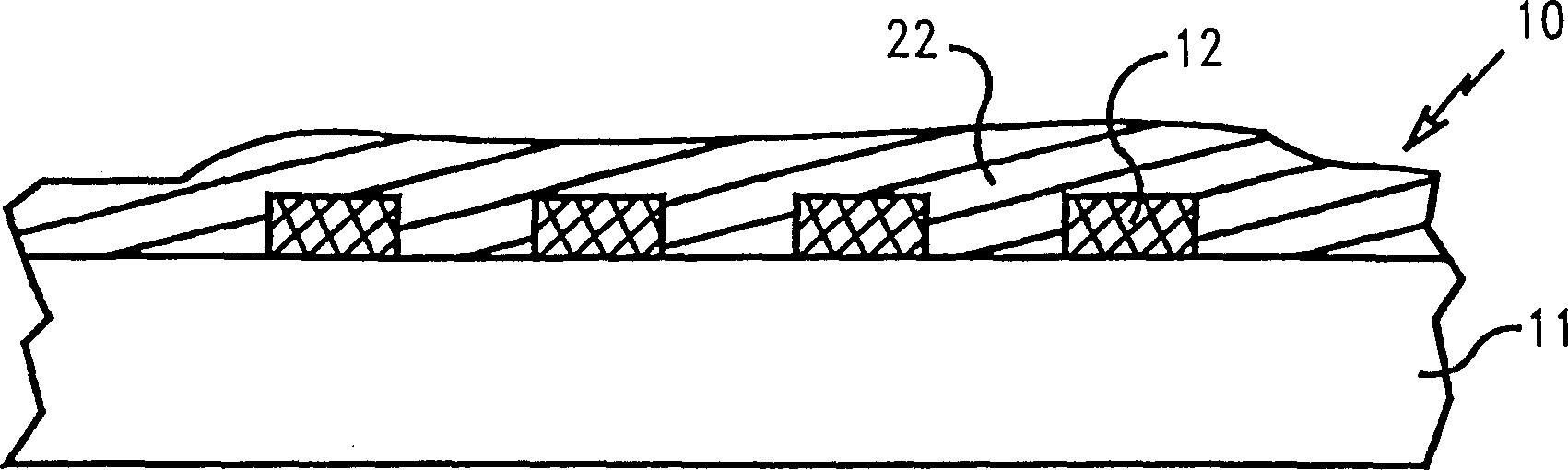

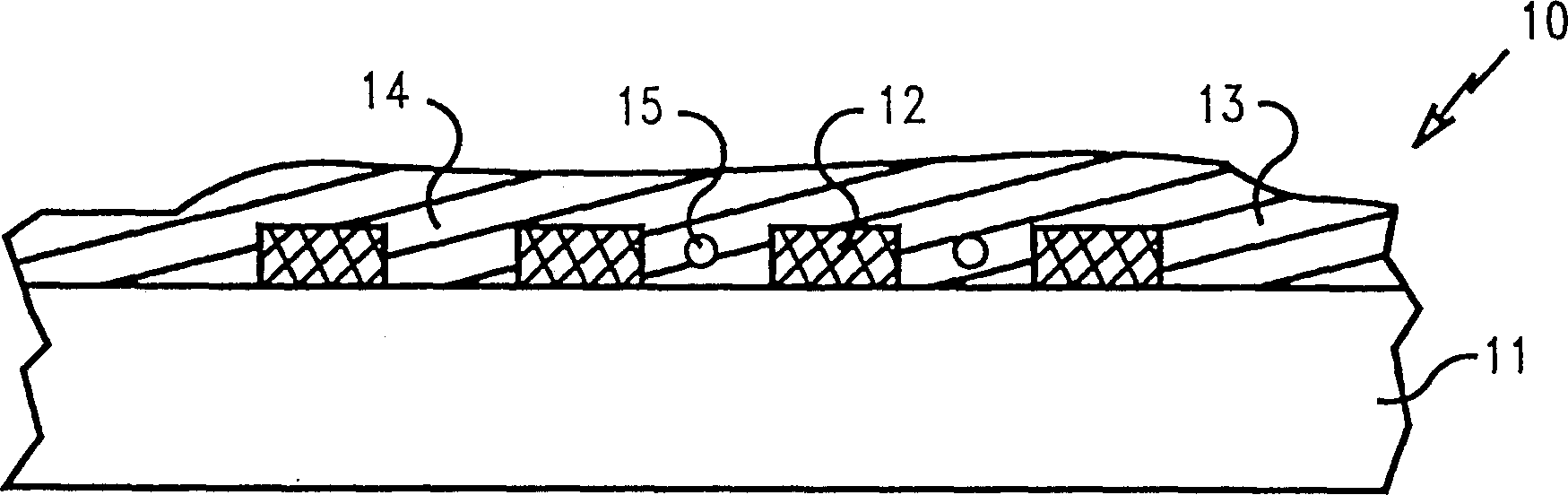

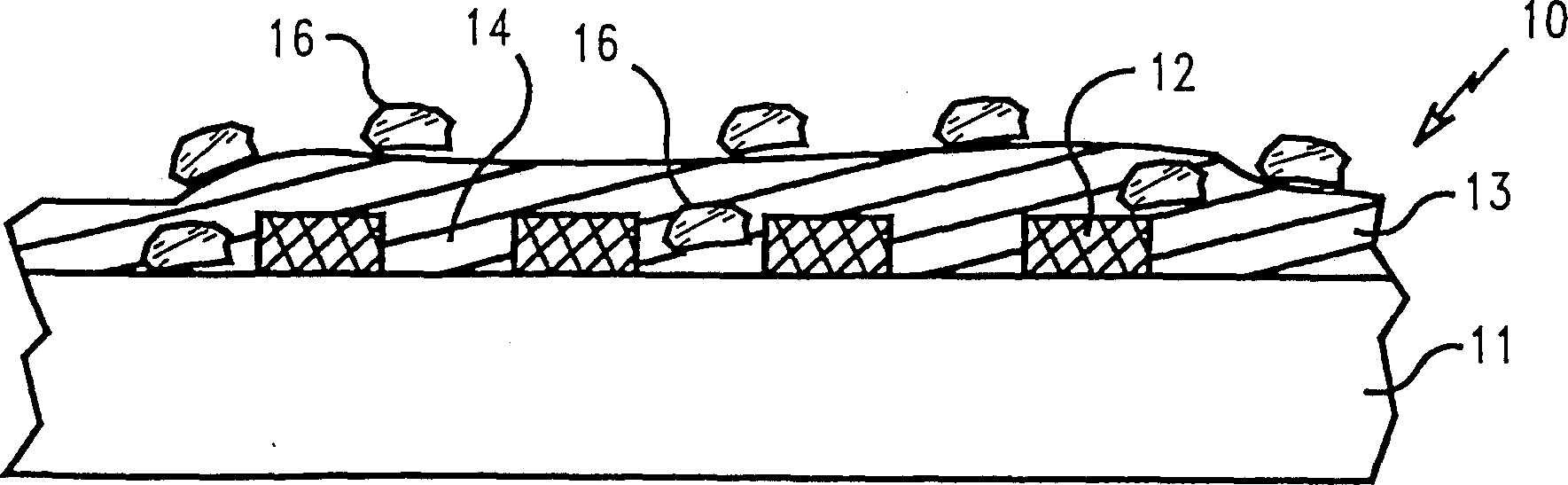

[0030] In describing the preferred embodiment of the invention, reference will be made to Figure 1-4 , wherein the same reference numerals represent the same elements of the present invention. The various elements of the invention in the figures are not necessarily drawn to scale.

[0031] According to the present invention, a fluorine-containing BPSG insulating planar layer (hereinafter referred to as F-BPSG) is formed on the surface of semiconductor wafers and other electronic component substrates. This F-BPSG layer is characterized as being substantially free of voids and surface crystals, and is a glass layer that can be easily reflowed at relatively low reflow temperatures consistent with presently proposed semiconductor wafer fabrication processes.

[0032] The term "semiconductor wafer" as used herein is meant to include wafer surface structures such as bumped leads, trenches, and transistors. The composition of structures on the surface of a semiconductor wafer is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com