Rhodium triiodid preparation method

A technology of rhodium triiodide and hydriodic acid, which is applied in iodide preparation, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of uncontrollable reaction conditions, unavoidable chlorine, etc., and achieve easy washing and filtration, and less loss of rhodium Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

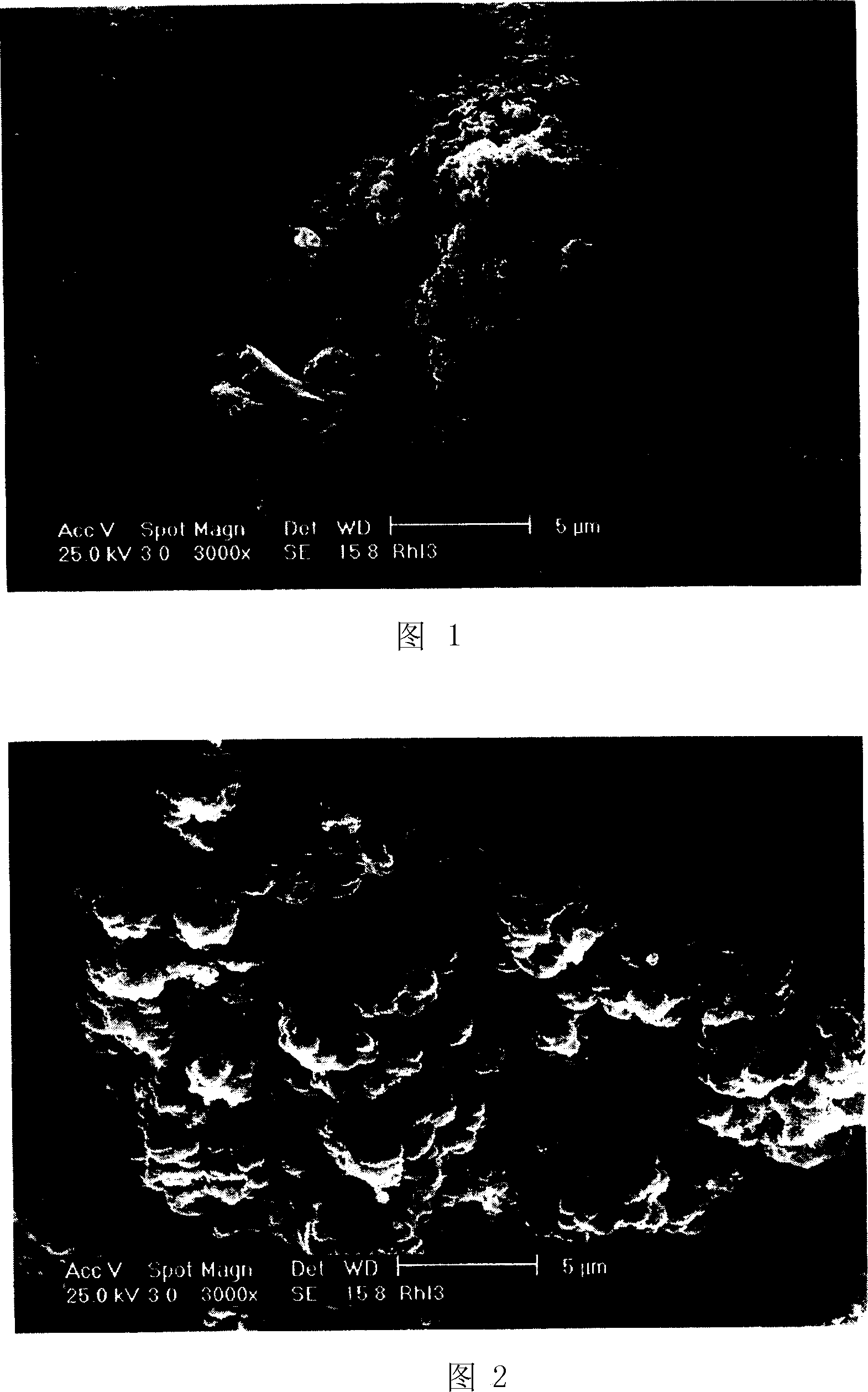

[0021] Add the hydroxide of 5g trivalent rhodium in the there-necked flask, then add 30ml of HI solution with a mass percent concentration of 45%, stir, heat to boiling, keep for 2 hours, then filter while hot, wash the filter cake, remove soluble impurities, When the conductivity in the washing solution is lower than 50 μS / cm, place the obtained product rhodium triiodide in an oven and carefully dry it. The final product obtained is gray black powder with a rhodium content of 22.3% and a single-pass yield of 75%. . It can be seen from Figure 1 that the particles have a loose porous structure with a diameter of less than 5 μm and uniform size.

[0022] The reaction filtrate can be directly recycled. Add 45% HI solution to the filtrate and repeat the previous process to convert the trivalent rhodium hydroxide in the filtrate into products. The total yield of rhodium can be close to 100% after determination.

Embodiment 2

[0024] Change the amount of HI solution to 40ml, and other operations are the same as in Example 1, the rhodium content is 21.3%, and the yield per pass is 78.5%.

Embodiment 3

[0026] Change the reaction time to be 4 hours, other operations are the same as in Example 2, the rhodium content is 19.5%, and the yield per pass is 92.0%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com