Paper pulp packing material and mfg. method thereof

A technology of packaging materials and manufacturing methods, applied in the field of pulp sheets and pulp molded products, can solve the problems of lack of softness, poor impact cushioning, hardness, etc., and achieve the effect of not being easily scratched

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

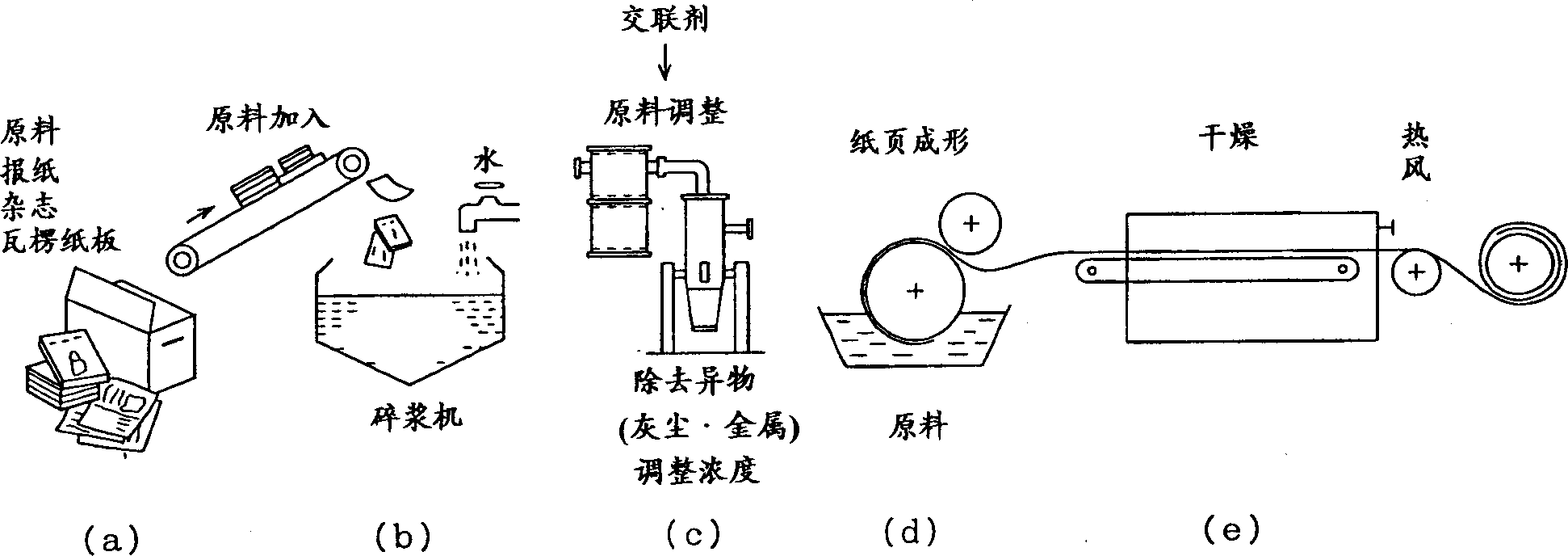

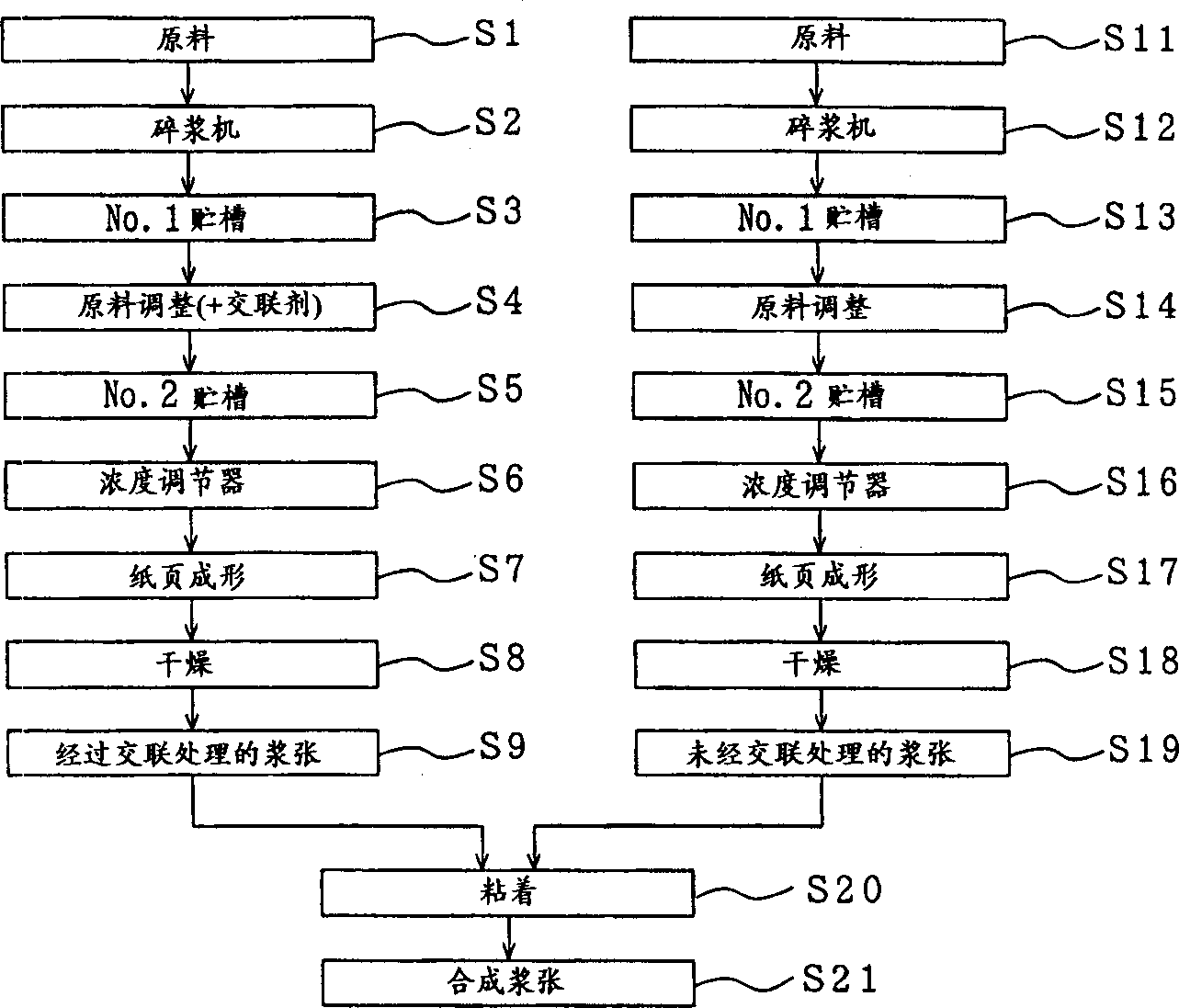

[0026] figure 1 It is an explanatory diagram of the pulp sheet manufacturing method according to Embodiment 1 of the present invention, figure 2 Flow chart of its fabrication method.

[0027] First, waste paper (pulp) such as newspapers, magazines or corrugated cardboard as raw materials is added to the pulper, and water is added to soften and disperse ( figure 1 (a, b), figure 2 , S1-S2). Next, store the impregnated, softened and dispersed raw material in No. 1 storage tank, and slowly supply it to a stock adjuster. Cross-linking agents such as epichlorohydrin make the pulp fiber cross-linking reaction, store the adjusted raw material in the No2 storage tank, and slowly supply it to the concentration regulator to adjust its concentration ( figure 1 (c), figure 2 , S3-S6). Then, utilizing the raw material adjusted in this way, it is formed into a pulp sheet ( figure 1 (d), figure 2 , S7), it is dried to obtain a cross-linked pulp for the first layer ( figure 1 (e)...

Embodiment approach 2

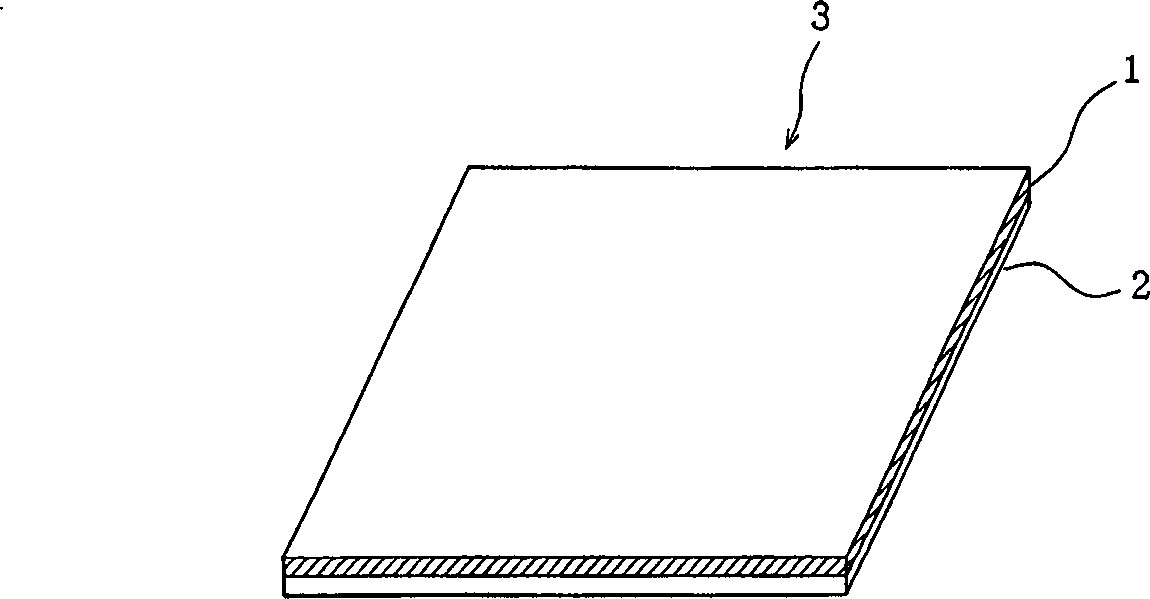

[0034] Figure 4 It is an explanatory diagram of the pulp sheet production method according to Embodiment 2 of the present invention. Here, PET (polyethylene terephthalate) or the above-mentioned biodegradable paper is sprayed and coated on one or both sides of the pulp sheet 4 mainly composed of uncrosslinked waste paper (pulp) and the like. After the powder of plastics 5 such as permanent plastics, heat treatment is carried out to it, pulp sheet 4 and plastics 5 are integrated, thus manufacture synthetic pulp sheet 6.

[0035] The synthetic pulp sheet 6 of making like this, though not having very high impact cushioning property, the pulp sheet without cross-linking treatment has shape retention, and the smoothness of the plastic surface coated on it is difficult for being scratched by the packaged object, And it is not easy for dust and dust to adhere. Therefore, it can be used as an outer packaging material or packaging material where a large impact is not generated.

[...

Embodiment approach 3

[0039] Figure 5 A flowchart illustrating a method for producing a synthetic pulp molded article according to Embodiment 3 of the present invention is shown.

[0040] Here, first put waste paper (pulp) such as newspapers, magazines or corrugated cardboard as raw materials into the pulper, add water to soak, soften and disperse ( Figure 5, S31-S32). Next, store the raw material in the No1 storage tank ( Figure 5 , S33), it is slowly supplied to the raw material adjustment machine, while iron flakes and foreign matter are removed, the components that have not been soaked and softened are soaked and softened, and cross-linking agents such as epichlorohydrin are added at the same time to make the pulp fibers undergo cross-linking reactions ( Figure 5 , S34), store the adjusted raw material in the No2 storage tank ( Figure 5 , S35), it is slowly supplied to the concentration regulator to adjust its concentration ( Figure 5 , S36). Then, the raw material is entered into a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com