Method and wire for reducing or eliminating resistance in power transmission line

A technology for power transmission lines and resistance, which is applied in the field of reducing or eliminating the resistance of power transmission lines, and can solve problems such as power loss, density influence, multi-consumption of non-ferrous metal materials, etc., to achieve the effects of reducing consumption, increasing density, and eliminating power loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

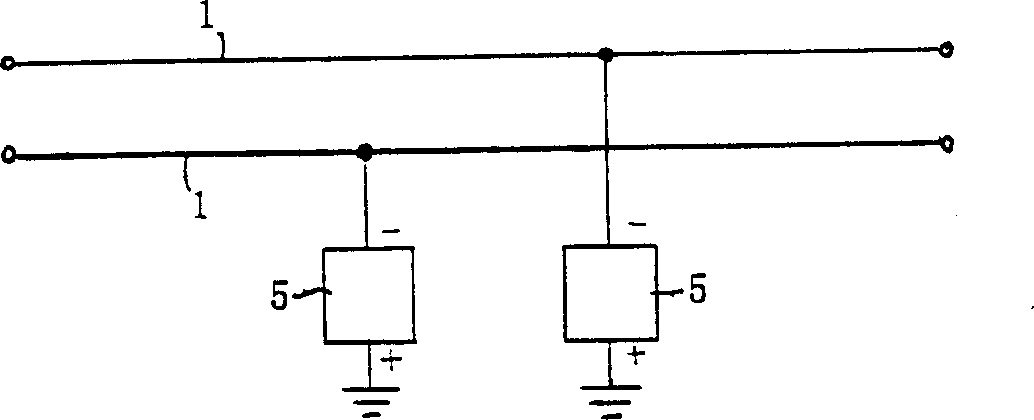

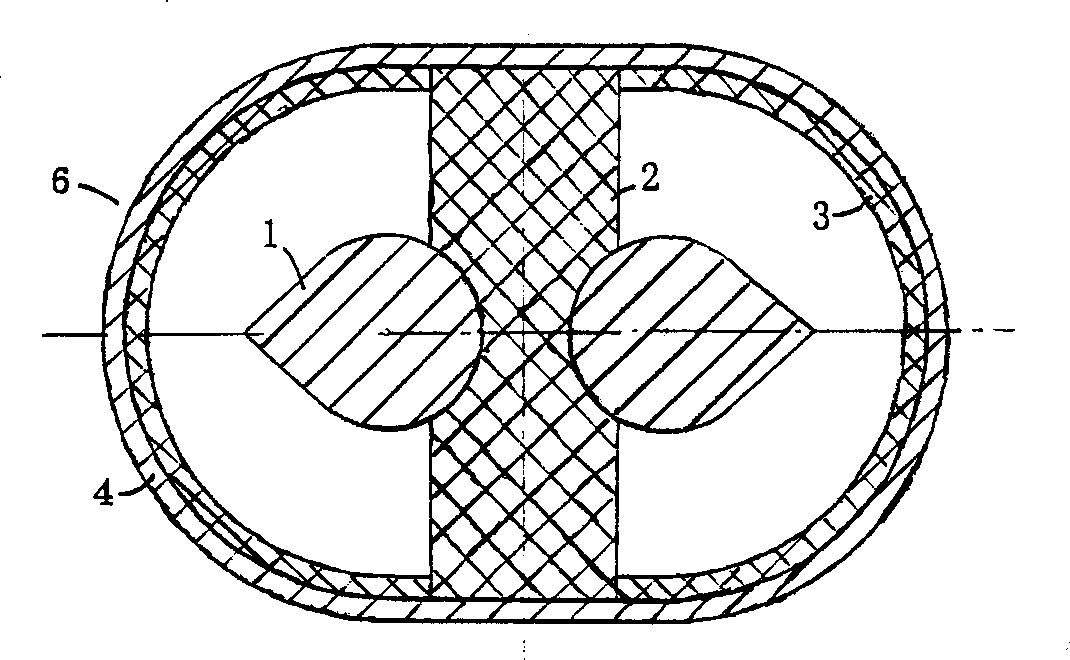

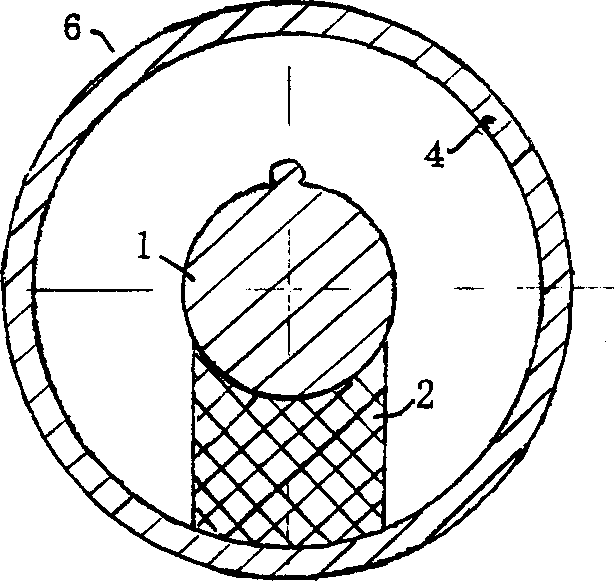

[0020] The method for reducing or eliminating the resistance of the power transmission line of the present invention includes making a lead 1 with a conductive material, connecting the negative pole of the electrostatic generator 5 or the high-voltage DC power supply 5 to the lead 1 of the power transmission line, and connecting the electrostatic generator 5 or the high-voltage The positive pole of the DC power supply 5 is grounded, and at least one electrostatic generator 5 or high-voltage DC power supply 5 is utilized to deliver negative charges to the lead 1, so that the lead 1 has a negative charge. According to the theory of quantum mechanics, the negative charge on the lead 1 will tend to Electron pairs are composed of electrons with parallel and opposite spins, and the negative charges on the wire 1 and / or electron pairs composed of negative charges are used to transmit electromagnetic field energy, and the resistivity of the wire 1 will be reduced or eliminated.

[0021...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com