Single optical fiber tracing type high precision continuous liquid level measuring method

A measurement method and tracking technology, applied in the field of measurement and control, can solve the problems of the long-term drift of the sensor, the measurement results are easily affected by the change of liquid density, and it is difficult to achieve high-precision measurement. Reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

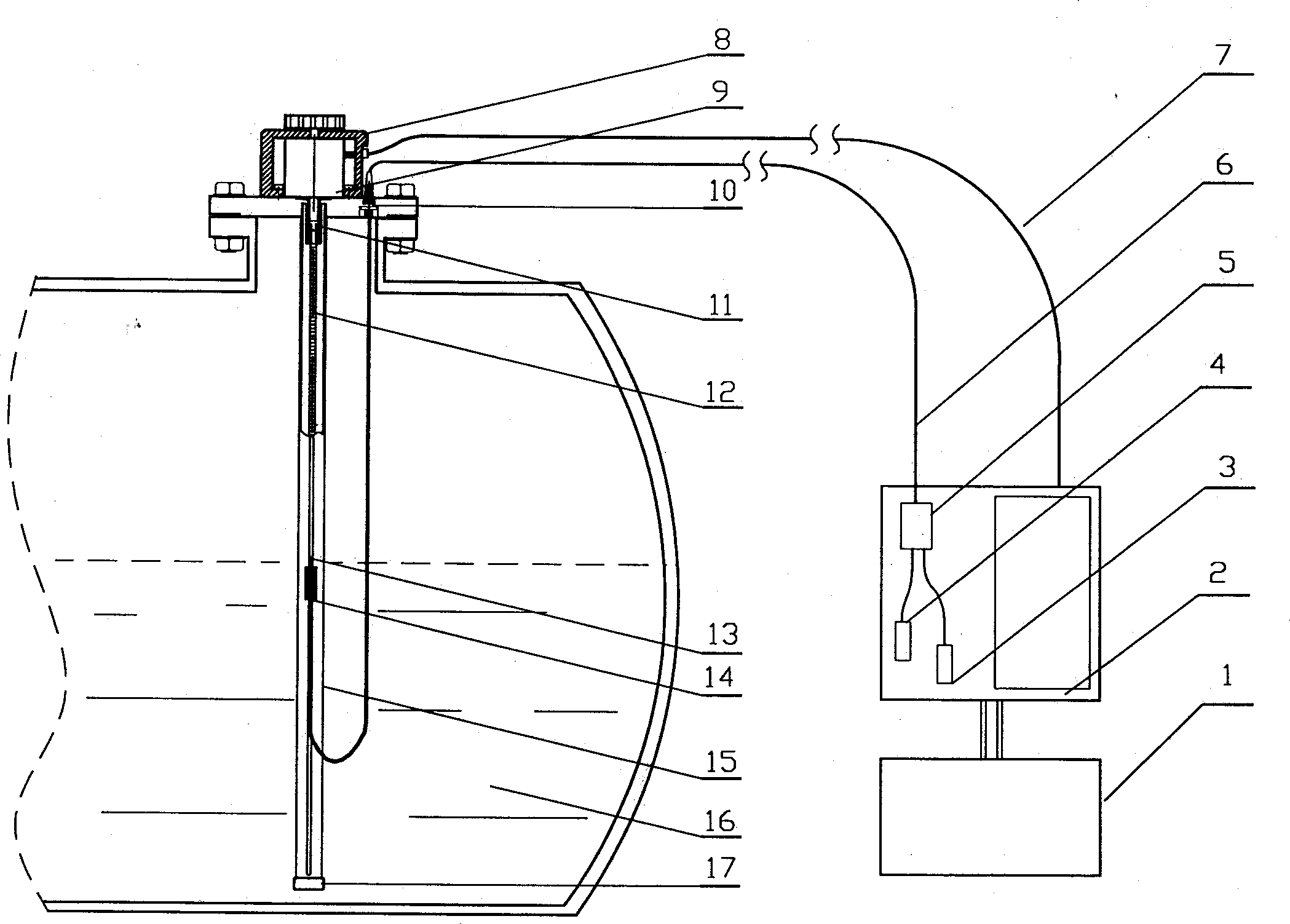

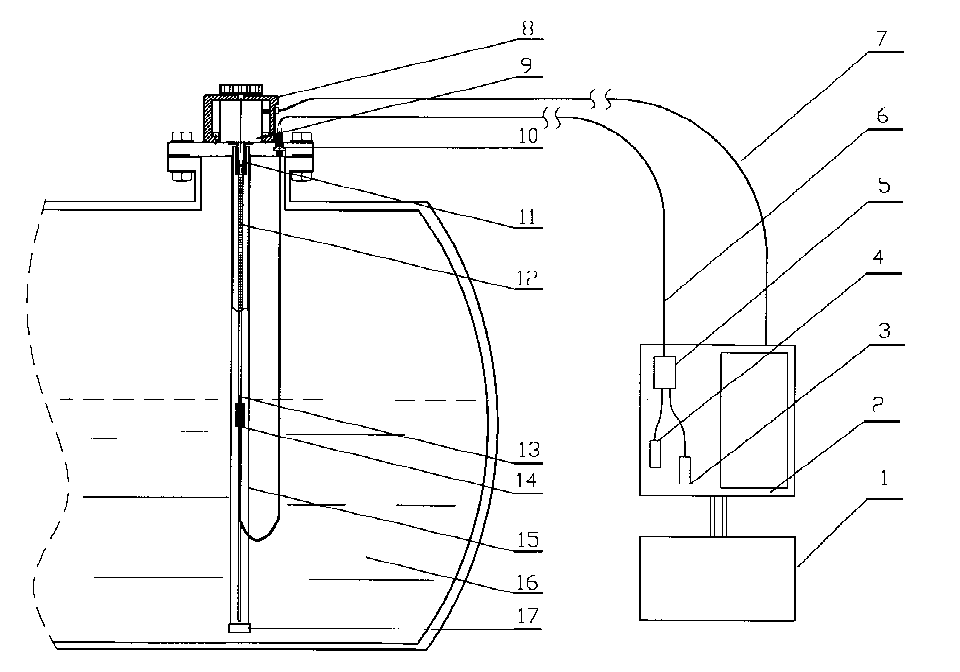

[0007] The best embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0008] As shown in the accompanying drawing, the optical signal with a central wavelength of 850nm sent by the LED (3) is transmitted to the optical signal fixed on the slider (14) through the optical fiber coupler (5), the single-core optical cable (6) and the sealed optical fiber union (10). Optical fiber sensing head (13). The sensing head is an 80-90 degree conical tip made by arc melting or optical grinding at the end of a common multimode communication fiber. When the probe is placed in the air, a part of the light can form total reflection at the tip of the cone, and transmit back to the PIN photodetector (4) via the same optical fiber (6) and coupler (5), and the intensity of the signal is I0; When the sensing probe is placed in the liquid (16), since the refractive index of the liquid is higher than that of the air, the total reflecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com