Transparent bar-type soap composition

A composition, bar-shaped technology, applied in the direction of soap detergent composition, transparent solid soap/detergent, detergent composition, etc., can solve problems such as lack of transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

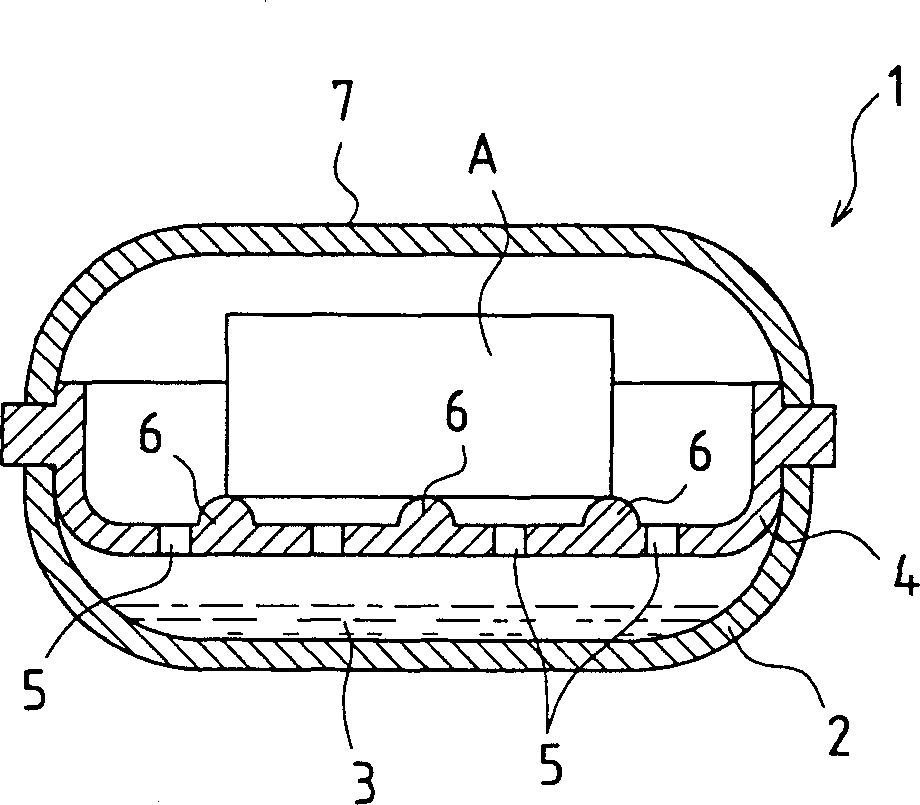

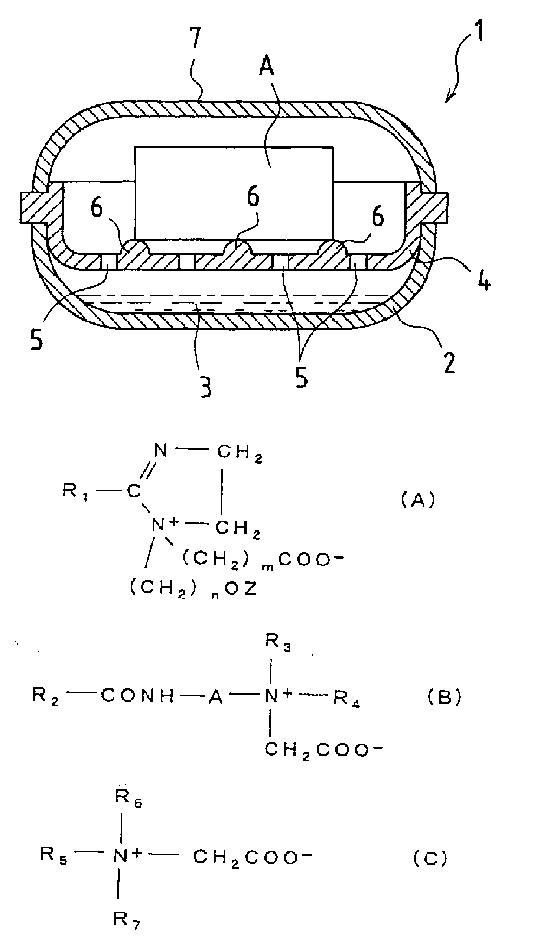

Image

Examples

Embodiment 1-5

[0049] First, mixed fatty acids were prepared according to the recipe listed in Table 1 and neutralized with aqueous sodium hydroxide solution. The neutralized mixture was dried to obtain mixed fatty acid sodium salts.

[0050] mixed fatty acids

mixed components

Mixing amount (parts by weight)

20

40

15

20

5

[0051] In the second step, according to the formula listed in Table 2, the composition of the transparent bar soap of Examples 1-5 was prepared by the method described below. In these soap compositions, the amount of mixed fatty acid sodium salts differs from one another.

[0052] mixed components

Example

1

2

3

4

5

20

25

30

35

40

Cocoimidazolinium Betaine

5

...

Embodiment 6-8

[0121] Mixed fatty acids were prepared according to the formula listed in Table 4, and neutralized with aqueous sodium hydroxide solution. The neutralized mixture is dried to obtain mixed fatty acid sodium salts.

[0122] mixed fatty acids

mixed components

Mixing amount (parts by weight)

20

10

20

30

35

[0123] In the second step, according to the formula listed in Table 5, the composition of the transparent bar soap of Examples 6-8 was prepared by the method described below. In these soap compositions, the amount of mixed cocoimidazolinium betaines differed from one another.

[0124] mixed components

Example

6

7

8

mixed fatty acid sodium salt

25

25

25

Cocoimidazolinium Betaine

2

7

10

Polyoxyethylene (60)...

Embodiment 9-12

[0133] First, mixed fatty acids were prepared according to the recipe listed in Table 7 and neutralized with aqueous sodium hydroxide solution. The neutralized mixture was dried to obtain mixed fatty acid sodium salts.

[0134] mixed fatty acids

mixed components

Mixing amount (parts by weight)

30

15

20

35

[0135] In the second step, according to the formula listed in Table 8, the composition of the transparent bar soap of Examples 9-12 was prepared by the method described below. In these soap compositions, the amount of polyoxyethylene (35) polyoxypropylene (40) diol was different from each other.

[0136] Coordinated components

Example

9

10

11

12

mixed fatty acid sodium salt

30

30

30

30

Cocoimidazolinium Betaine

5

5

5

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com