Induction heating device for roll and induction heating method

An induction heating device and induction heating technology, applied in induction heating device, induction heating, induction heating control and other directions, can solve the problems of increased high frequency loss of feeder, decreased heating efficiency, increased loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

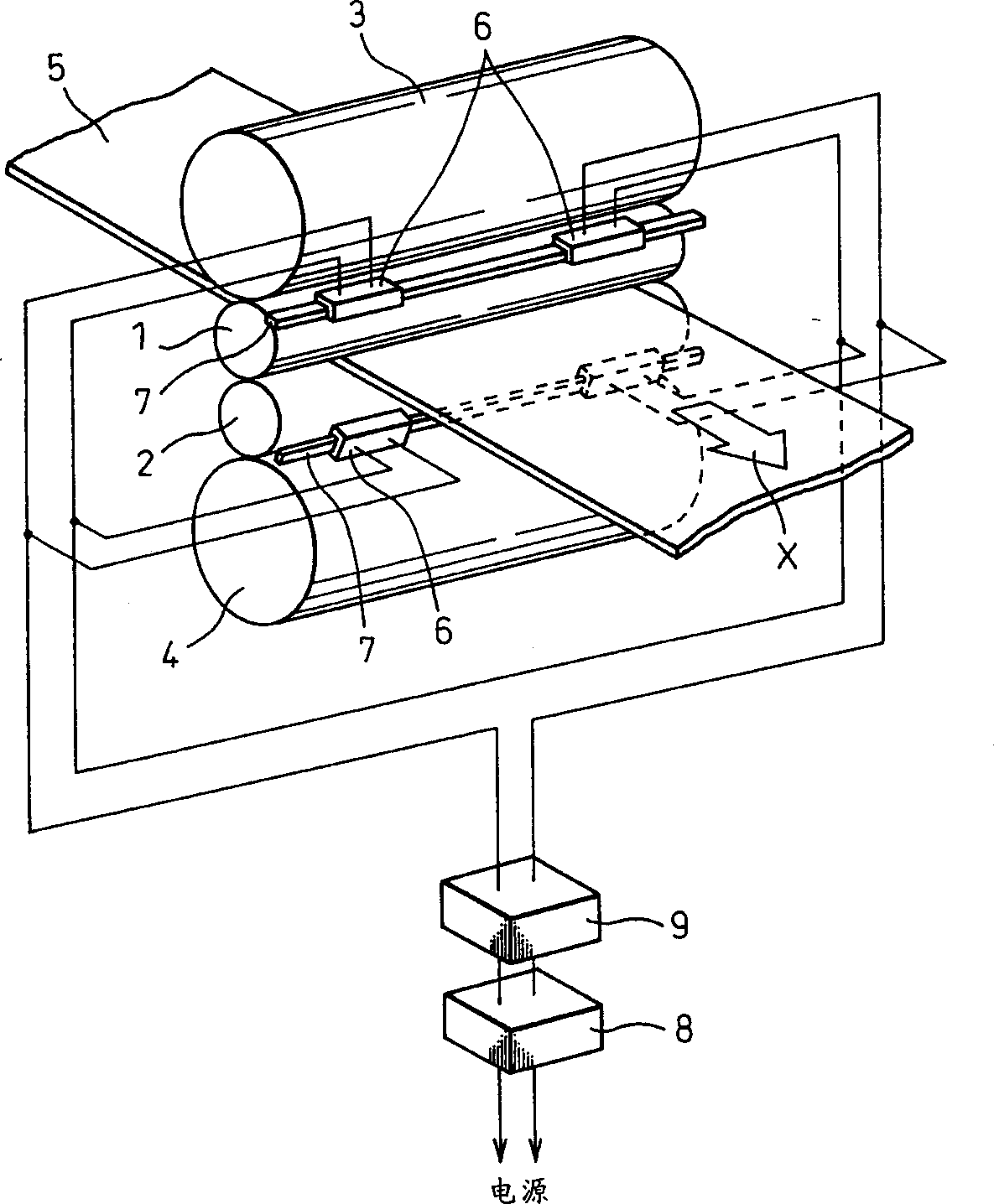

[0026] figure 1 is a schematic diagram for explaining the induction heating device for the roll of the present invention. The basic structure of the induction heating device and Figure 7 The basic structure of the prior art shown is the same. There are four induction heaters 6 arranged on the delivery side (entry side) of the work rolls 1, 2 so that each induction heater 6 can slide on the sliding track 7 arranged parallel to the axis of the work rolls 1, 2, and the induction heater 6 Arranged relative to work rolls 1 and 2. The structures of these induction heaters 1, 2 are the same as those in the prior art, and are powered by a power supply 8.

[0027] However, this power supply unit 8 differs from the prior art power supply 8' in that the power to be supplied to the induction heater 6 is not regulated, but rather provides power of approximately constant intensity. Between the power supply unit 8 and the induction heater 6, a frequency control unit 9 for adjusting the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com