Dehydrogenation method of CO2 raw material gas for synthesizing urea

A carbon dioxide, raw gas technology, applied in chemical instruments and methods, preparation of organic compounds, inorganic chemistry, etc., can solve problems such as unusability, and achieve the effect of eliminating explosions, eliminating explosion hazards, and solving potential safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

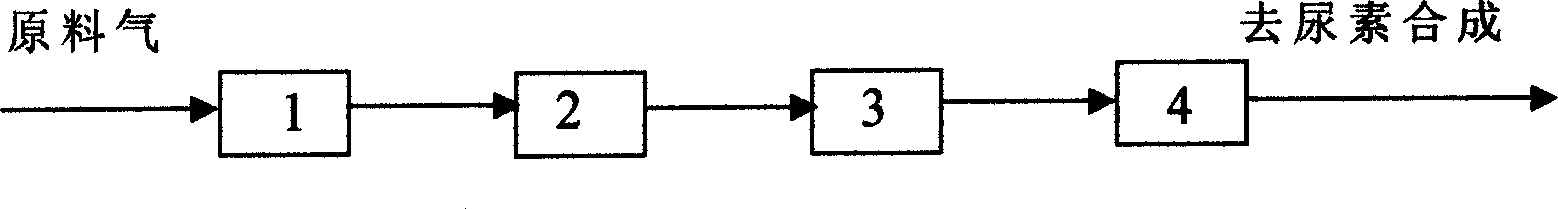

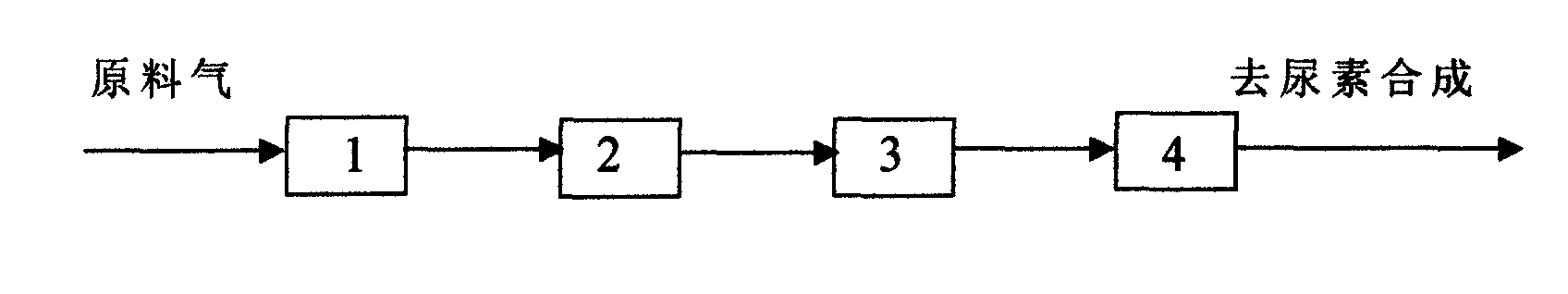

[0018] A certain nitrogenous fertilizer plant uses coal as raw material, and when the urea production capacity of expansion and transformation reaches 200,000 tons / year, the CO2 raw material gas dehydrogenation method for urea synthesis of the present invention is adopted, and its process flow is shown in the attached figure 1 As shown, when the inlet temperature of the TH-2 dehydrogenation catalyst is at 140-160°C, the H2 content can be removed from 0.3-0.6% to 50-300ppm, and a satisfactory effect has been achieved. Table 1 lists five operations Monthly and 10-month data.

[0019] Table 1 Data of urea dehydrogenation new technology running for 5 and 10 months in 2000

[0020] Date (May)

Outlet temperature °C

Date (October)

Outlet temperature °C

1

140-143

160-165

1

150-155

170-175

3

140-149

160-167

3

150-153

170-174

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com