Ball milling process of preparing lithium nitride for negative electrode material of lithium ion battery

A technology for lithium ion batteries and negative electrode materials, which is applied in the directions of alkali metal compounds, lithium compounds, battery electrodes, etc., and can solve the problems of high reaction temperature, complicated operation, and long time consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

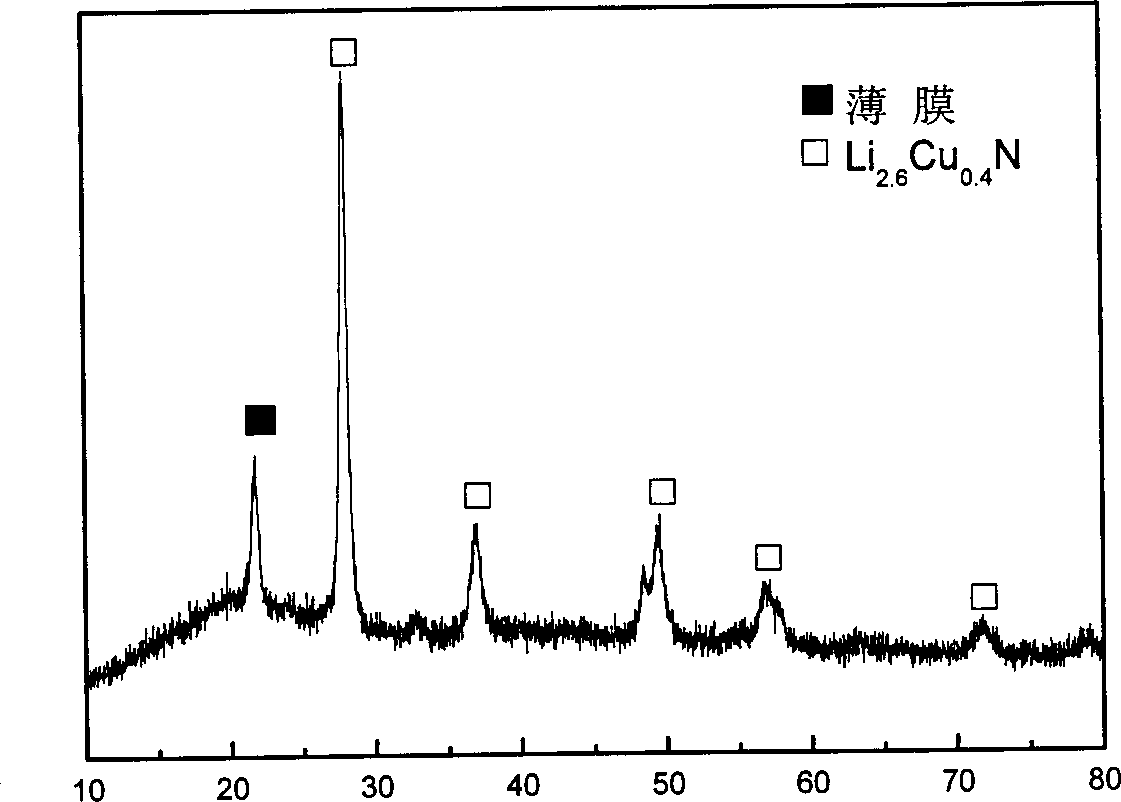

[0027] Preparation of lithium-copper-nitride negative electrode material. Under an Ar atmosphere, a certain amount of lithium nitride powder and metal copper powder (200 mesh) were uniformly mixed according to the ratio of Li:Cu=2.6:0.4, and placed in a Planetary Mono Mill Pulverisette type 6 ball mill. The capacity of the ball mill container is about 80ml, and fifteen steel balls with a diameter of 10mm are built in the container. Both the grinding steel balls and the ball mill container are made of stainless steel. Fill a certain amount of N into the ball mill container 2 The gas is then sealed by an O-ring. The ball mill was rotated at a frequency of 500 rpm for 5 hours at room temperature.

[0028] The prepared Li 2.6 Cu 0.4 The lithium intercalation capacity of the N material for the first time is 750mAh / g, and the capacity retention rate after 20 cycles is 80% (the cut-off charge-discharge voltage is 0-1.3V).

Embodiment 2

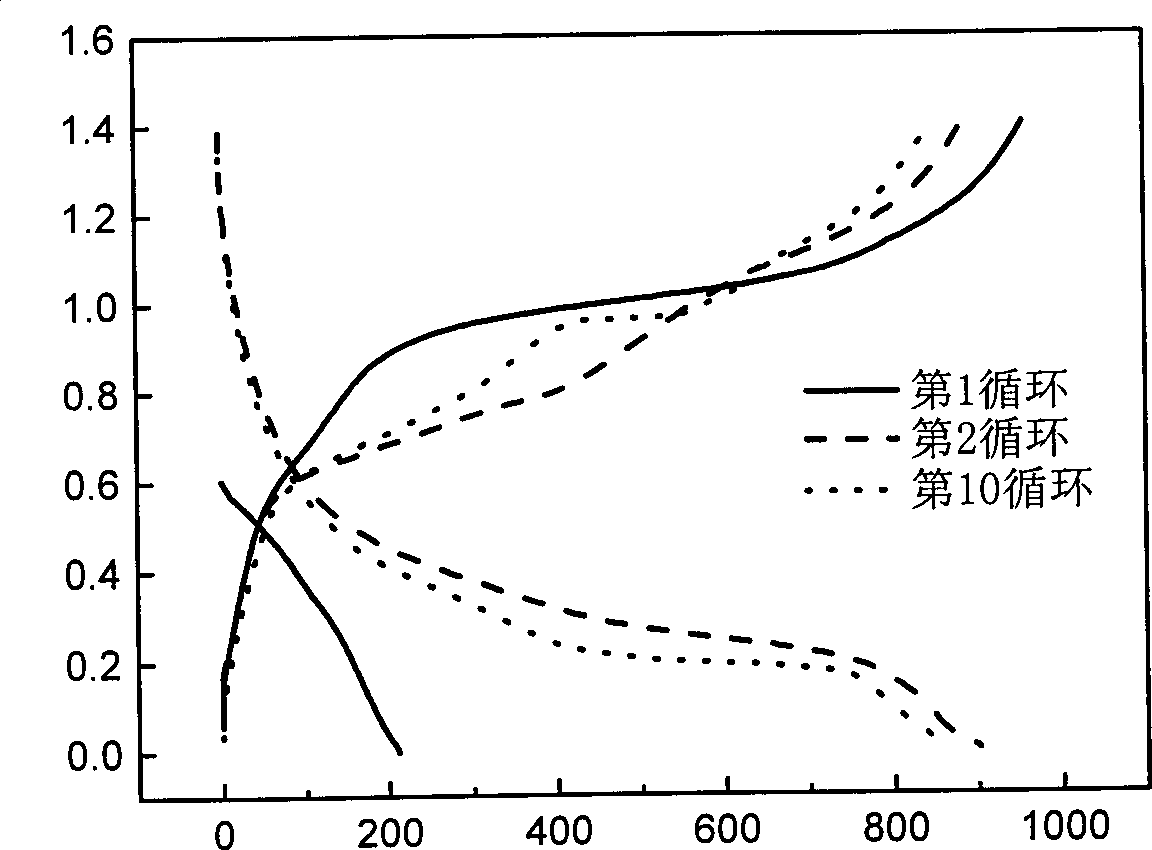

[0030] Preparation of lithium-cobalt-nitride negative electrode material. As described in Example 1, lithium nitride powder and metal cobalt powder (200 mesh) were ball milled in a high energy ball mill for 5 hours according to the ratio of Li:Co=2.6:0.4. The prepared Li 2.6 co 0.4 The first delithiation capacity of the N material is 950mAh / g, and after 10 cycles, the intercalation and delithiation capacity is still 850mAh / g (the cut-off charge and discharge voltage is 0-1.4V).

Embodiment 3

[0032] Preparation of lithium-nickel-nitride negative electrode material. As described in Example 1, lithium nitride powder and metal nickel powder (200 mesh) were ball-milled in a high-energy ball mill for 10 hours according to the ratio of Li:Ni=2.5:0.5. The prepared Li 2.5 Ni 0.5 The reversible intercalation and delithiation capacity of N material is 460mAh / g, while the reported Li 2.5 Ni 0.5 N reversible lithium intercalation capacity is 200mAh / g (cut-off charge and discharge voltage 0-1.4V).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com