Filtration and purification system for pH neutral solutions

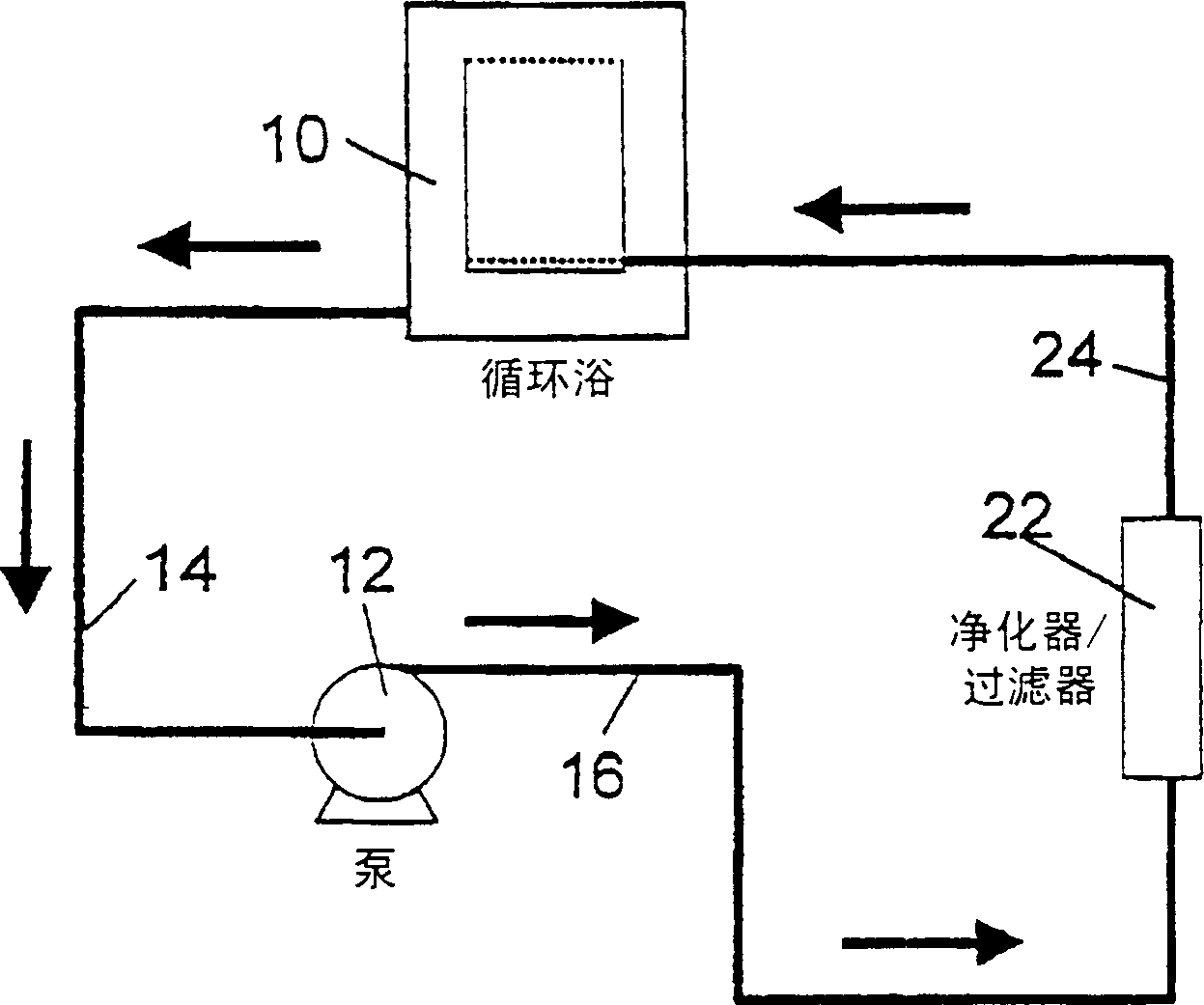

A neutral solution and solution technology, which is used in the field of filtration and purification systems for pH neutral solutions, can solve the problems of reducing the porosity of composite materials, reducing the flow rate of liquids passing through porous composite materials, and achieving the effect of small mass transfer resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Embodiment 1

[0039] Examples Example 1: Continuous immobilization of multiple ligands

[0040] This example describes the use of a cartridge (10,000 cm surface area) containing a folded film of hydrophilic polyethylene 2 ) (ETCHGUARD(R); Millipore Corp.) with three ligands (SL 415, SL 420, and SL 407; IBC Advanced Technologies, Inc., American Fork, Utah) immobilized sequentially. The SL 415 ligand was first immobilized on the membrane. The cartridge was activated with 15 gms EDAC in 1.2 L of DI water for 15 minutes, followed by the addition of 15 gms EDAC in the same solution over 10 minutes or more. In the coupling step, the activation cassette was contacted with 59 gms SL 415 macrocyclic ligand solution in 1 L DI water. The coupling is effective with or without decanting the activation solution, and the contact time for the coupling reaction can be several hours or as long as overnight. Cassettes were washed with DI water in preparation for secondary ligand att...

Embodiment 2

[0042] Next, the third ligand SL 420 is immobilized in the same steps as the activation and coupling described above. The activation medium was 1.2 L of 75% IPA and 25% DI water. The SL 420 ligand was prepared by dissolving 30 gms ligand in 1 L of 75% IPA (790ml) and 25% DI water (210ml). After the coupling reaction, the cartridge was washed with a mixture of 75% IPA (790ml) and 25% DI water (210ml). Membranes were treated with cassettes to determine macrocyclic ligand capacity. Its Cu capacity is 0.034mol / cm 2 . Example 2: Simultaneous immobilization of multiple ligands

[0043] This example describes the use of a cartridge (10,000 cm surface area) containing a folded film of hydrophilic polyethylene 2 ) (ETCHGUARD®; Millipore Corp.) co-immobilized three ligands (SL 415, SL 420 and SL 407; IBC Advanced Technologies, Inc.). The SL 415 ligand was first immobilized on the membrane. The cartridge was activated with 15 gmsEDAC in 1.2 L DI water for 15 minutes, followed by t...

Embodiment 3

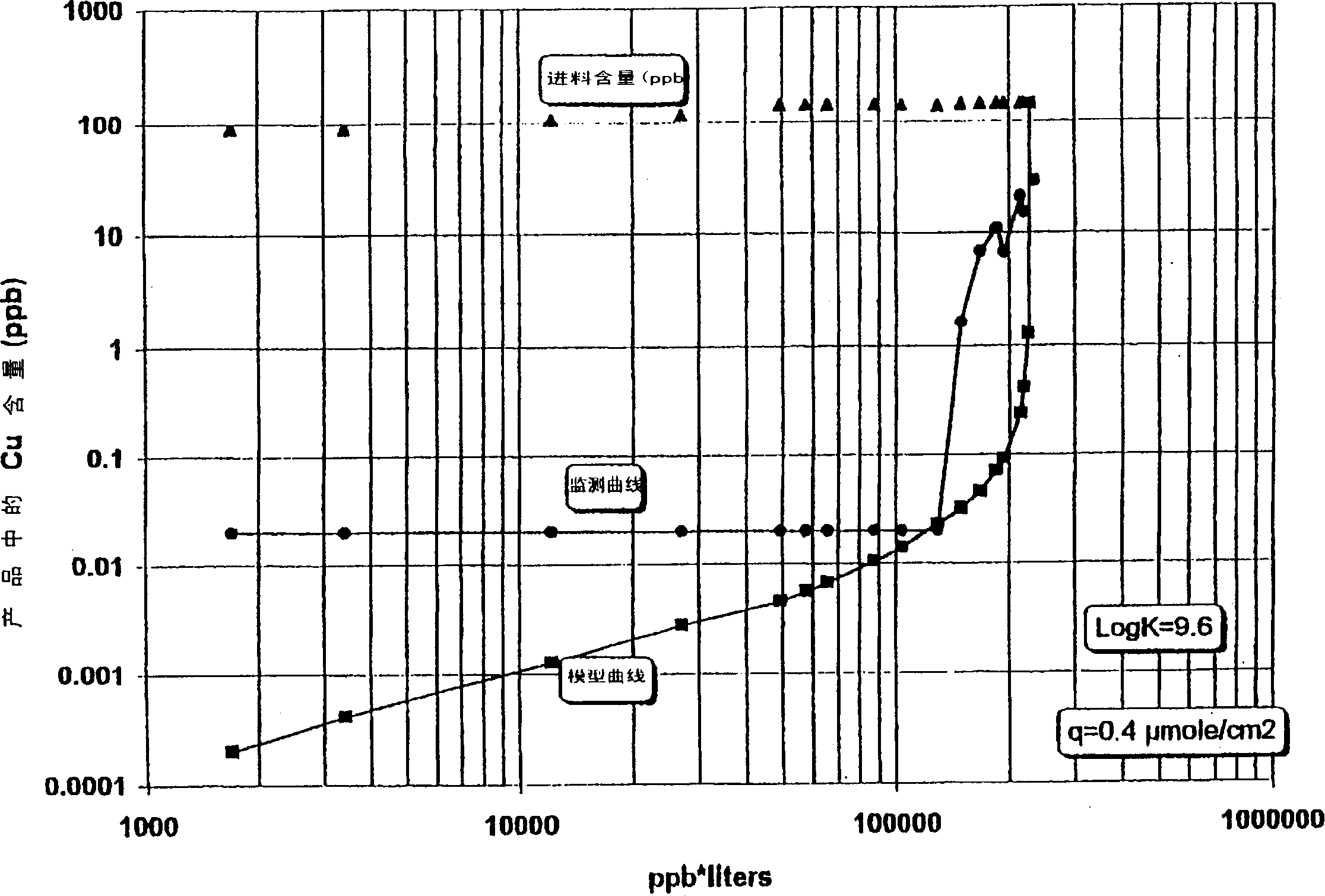

[0045] Embodiment 3: the purification of water

[0046] This example describes the purification of an aqueous solution containing Cu in a single-pass flow mode using a ligand membrane device of the present invention. This solution was passed through a folding cartridge device made with Cu-ligand (SL 420)-immobilized-membrane (hydrophilic polyethylene). The device has a membrane area of about 10,000 cm 2 And the ligand capacity is 0.4mol / cm 2 (SL 420). The feed concentration was maintained at about 100 ppb Cu and the solution flow rate was maintained at 1 gpm. The Cu concentration of the purified product (effluent) was monitored to determine its breakthrough rate. The Cu concentration (ppb) in the product is relative to the total volume throughput (in ppb * L represents), that is, the product of the total volume of the processed product (liter) and the feed concentration (ppb), plotted, and the results are plotted in figure 2 . The data shows that the purifier continuo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface area | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com