Diluted magnetic ZnO-base semiconductor prepared by sol-gel method

A technology of magnetic semiconductor and gel method, which is used in semiconductor/solid-state device manufacturing, inorganic material magnetism, inductor/transformer/magnet manufacturing, etc. It can solve the problems of difficult to obtain p-n junction homogeneous contact and difficult to obtain p-type materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

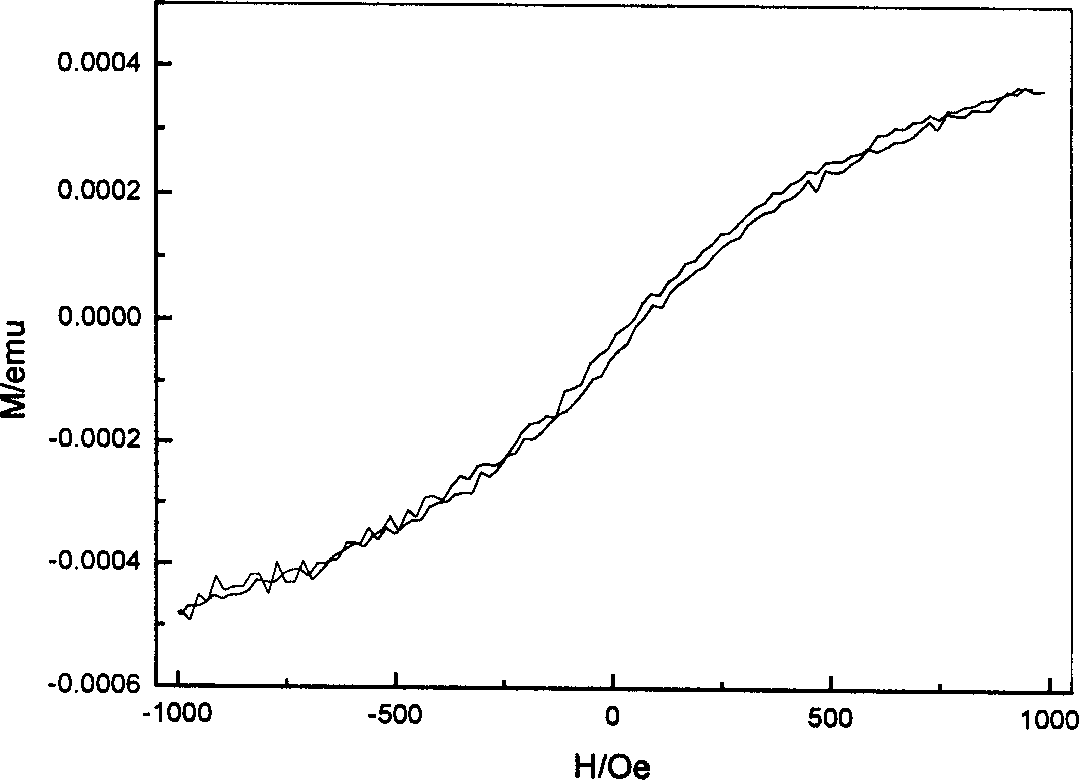

Image

Examples

Embodiment Construction

[0012] Specific steps are as follows:

[0013] 1. Prepare ZnO colloidal solution. Dissolve a certain amount of analytically pure zinc acetate and ferrous chloride in absolute ethanol, and stir evenly

[0014] Stir, and add an appropriate amount of lactic acid dropwise until the solution is about to precipitate. Stirring was continued for 2 hours. Finally get ZnO glue

[0015] body solution. The atomic concentration ratio of iron and zinc is 1 to 15%; the colloidal ratio of Mn, Co and Ni is the same as that of Fe, also in

[0016] 1~15%. Salts of Mn, Co and Ni can be used, as well as chlorides or sulfates.

[0017] 2. Add a drop of 0.02ml of ZnO colloidal solution on the pre-cleaned Si wafer,

[0018] The rate is uniformly coated on the Si wafer.

[0019] 3. The film is placed at room temperature to 100°C for 10 to 30 minutes, and then heat-treated at 240 to 300°C for 5-10 minutes.

[0020] 4. Repeat steps 2 and 3 above several times to obtain ZnO films with differe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com