Movable injection station and its injection and polymerization technique

A technology of injection system and mother liquor, which is applied in the fields of production fluids, wellbore/well components, earth-moving drilling, etc. It can solve the problems of inability to adapt to different blocks and formations of oil fields, difficult maintenance, and low utilization rate, and achieve easy relocation and repeatability. The effect of utilization, reduction of the number of equipment, and reduction of project investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

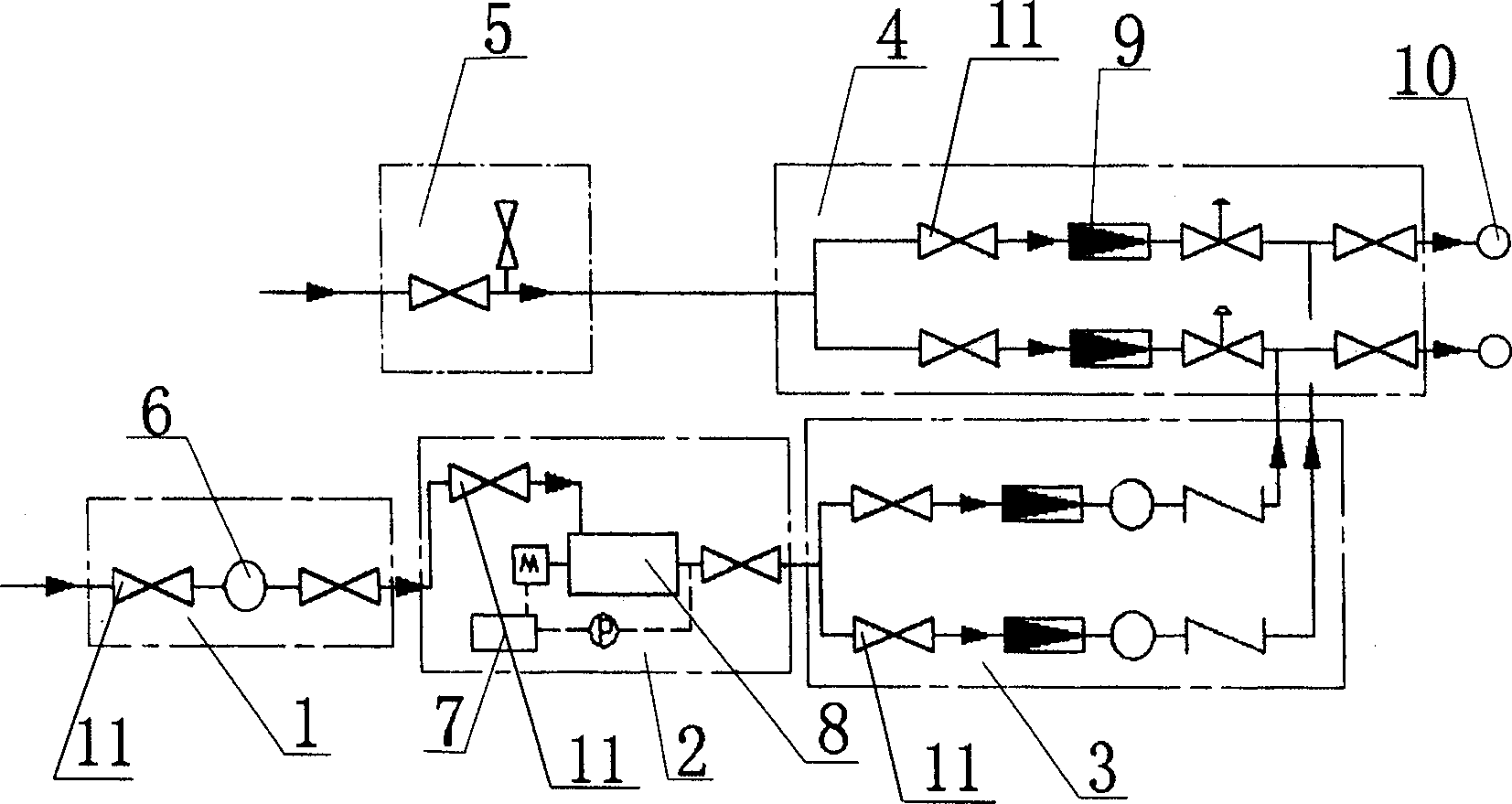

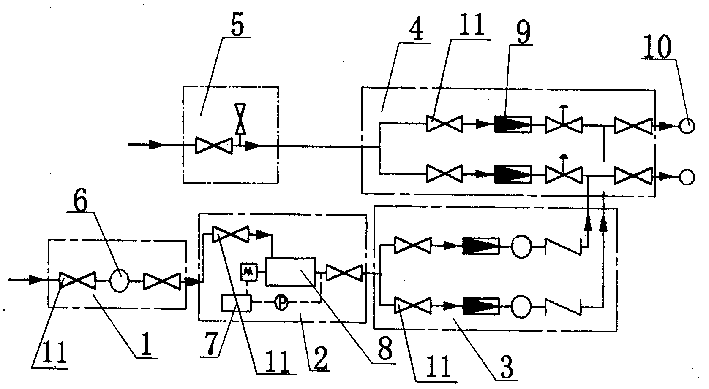

Image

Examples

Embodiment 1

[0024] Example 1: Part of the inventive technology was adopted in the production capacity construction of Xingsi 4~6 areas of No. 4 and Xingbei 1#~3#, 5#~8# injection stations in Daqing Oilfield No. 4 Plant. Taking "No. 6 Injection Station" as an example, 20 sets of injection pumps, 20 sets of valve groups, and 1 mother liquor storage tank will be built, and the project investment will be 6.30 million yuan. And use this invention, because cancel mother liquor storage tank, storage tank platform and valve chamber, reduce land occupation, saved engineering investment and be 500,000 yuan. After 3 to 4 years of production and operation, the injection pump room can be relocated as a whole for reuse.

Embodiment 2

[0025] Example 2: The technology of this invention has been completely adopted in Xingbei 4# injection station in the production capacity construction of Xingsi 4-6 area of No. 4 Oil Production Plant of Daqing Oilfield. The total investment of the original project is 5.91 million yuan, of which the relocation part investment is 3.93 million yuan, and 30% of the relocation part investment will be lost after demolition, transportation and installation; it covers an area of 3000m 2 . Using this invented technology, only one relocation can save investment of 2.76 million yuan in the construction of the new injection station, accounting for about 47% of the total investment of the new injection station, and only covers an area of 600m 2 , save the land area; at the same time, the injection station can be reused, and the relocation is convenient.

[0026] It can be seen that due to the reduction in the number of polymer injection pumps, the corresponding reduction in mechanic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com