Base material using vinegar sludge as raw material for cultivating seedling and cultivation and its production method

A manufacturing method and technology of vinegar grains, which are applied to the substrate for plant seedling raising and cultivation using vinegar grains as raw materials and the field of manufacture thereof, can solve the problem of high drying process cost, achieve easy operation, increased economic benefit and simple production process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

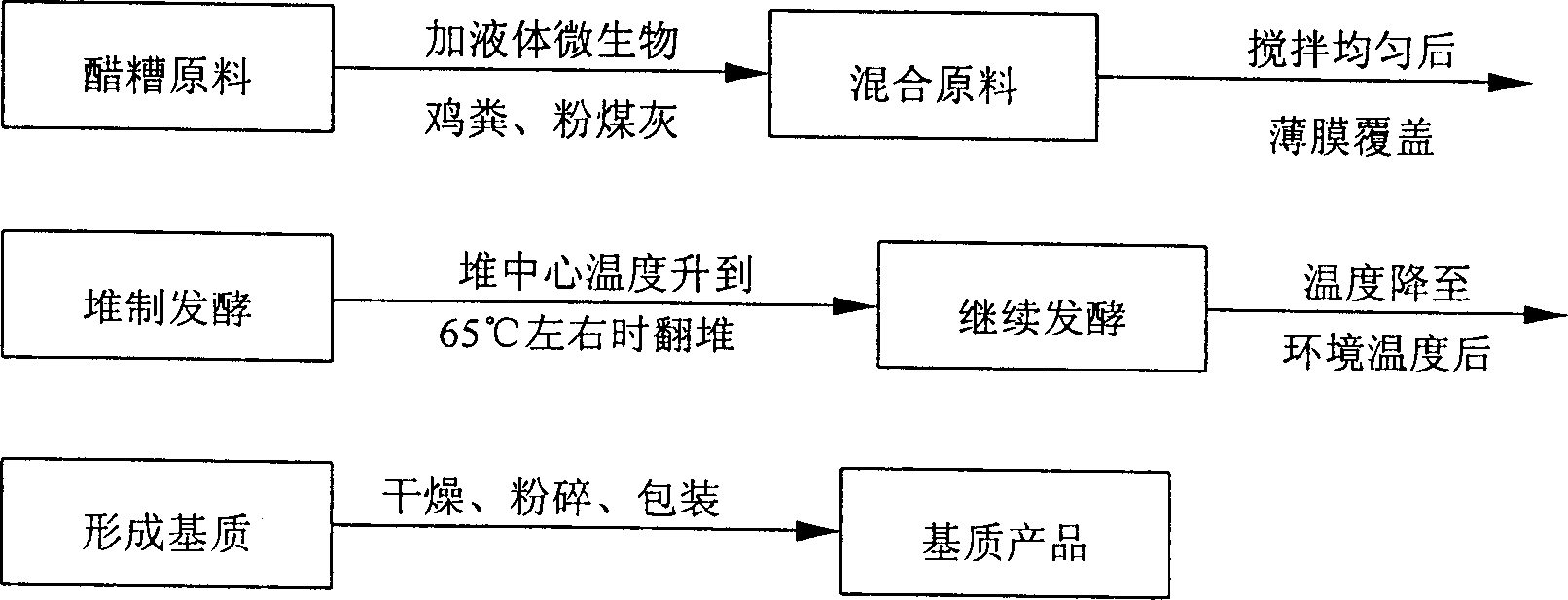

[0014] According to the process proposed in this study, the fermentation test of vinegar lees was carried out. Every 10 tons of ash was used, stirred evenly, covered with plastic cloth, and fermented. Use a temperature detector to measure the temperature change in the pile. When the temperature rises to 65°C, turn the pile once, then cover it with plastic cloth and continue to pile up. The implementation results show that the production process is practical and feasible, and the composting time needs 35 days from June to August, 45 days from October to November, and 55 days from December to January to complete the whole fermentation process.

[0015] The vinegar lees substrate fermented according to this method has been tested by many units in the suburbs of Zhenjiang City, Jiangsu Province, and the effect is good. Compared with conventional rockwool or peat mixture substrates, vegetables grown on vinegar residue substrates emerged faster and grew better. For example, the res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com