Process for purifying swainsonine by biofermentation

A technology of swainsonine and biological fermentation, applied in the field of bioengineering research, can solve the problems of low swainsonine content and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

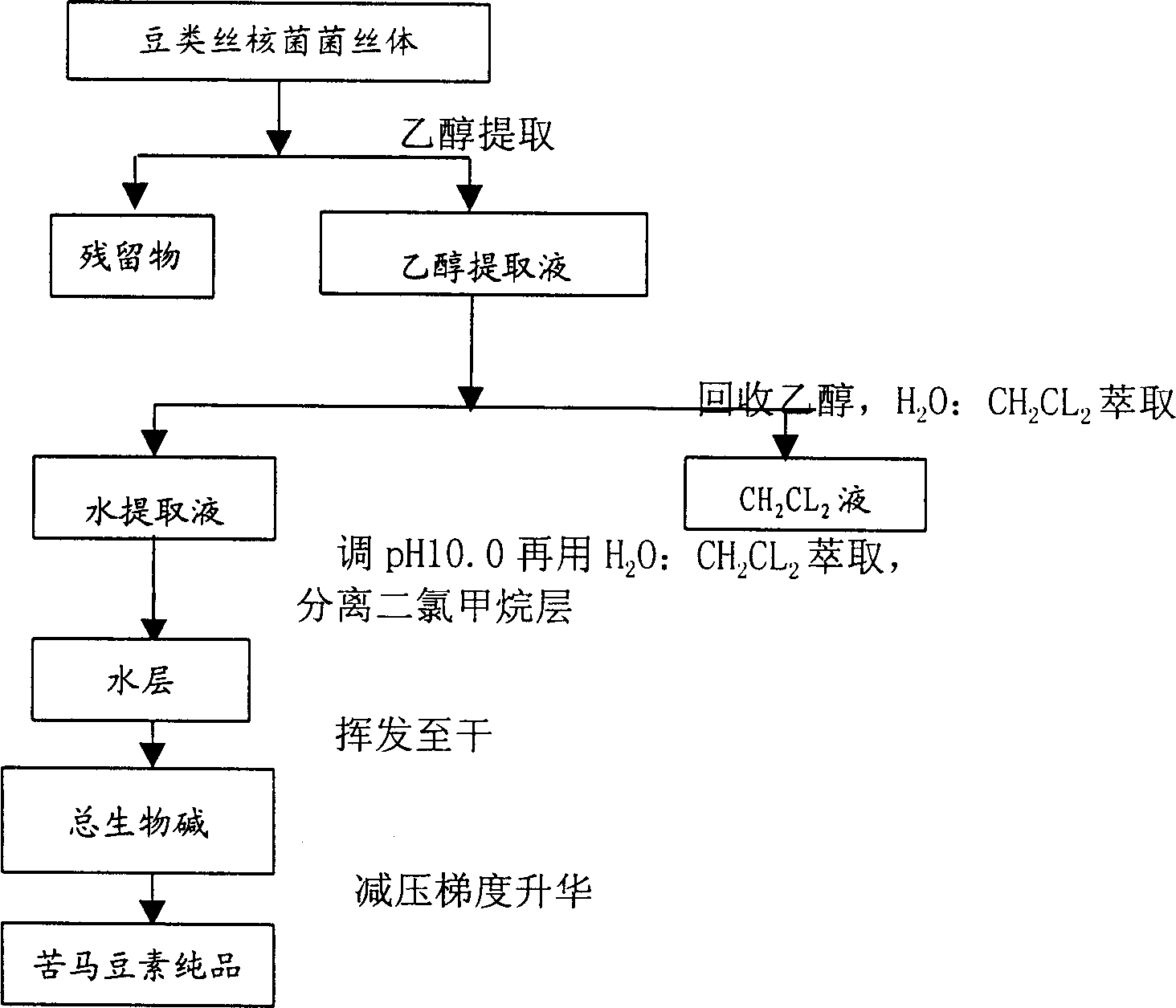

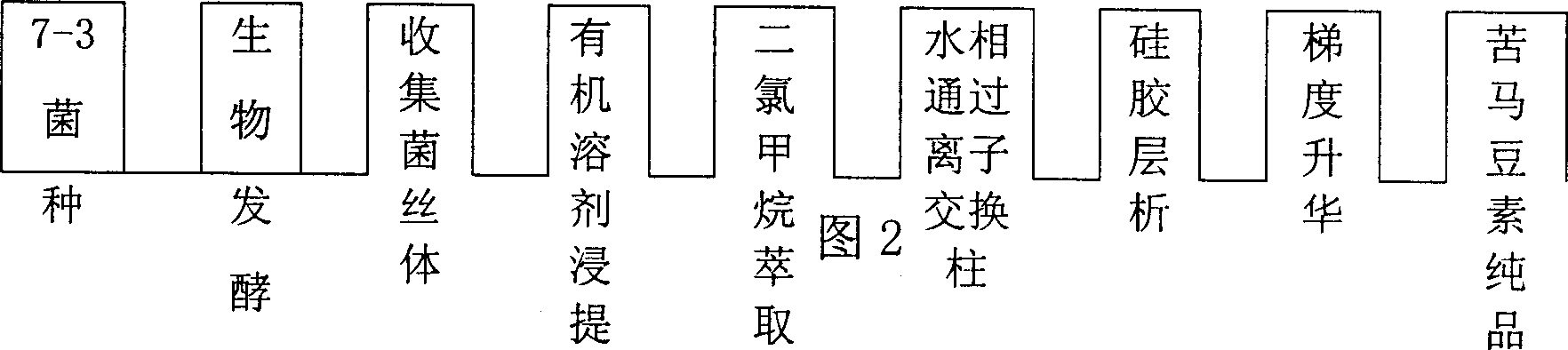

Method used

Image

Examples

Embodiment 1

[0021] Example 1: According to the technical scheme of the present invention, the process of purifying swainsonine is carried out in the following steps:

[0022] 1) Preservation of Rhizoctonia legumes 7-3: Inoculate the self-isolated Rhizoctonia legumes 7-3 PDA medium, store in a refrigerator at 4°C, and pass down once every 20 days;

[0023] The formula of PDA medium is: 200g peeled potatoes, 15g agar, 20g glucose, and 1000ml water;

[0024] 2) Rhizoctonia legumes 7-3 inoculation, culture, and mycelium collection: In a sterile state, inoculate 7-3 strains in Czapek's medium for biological fermentation, culture at 25°C for 2 weeks with aeration, and collect hyphae Body, dry, set aside;

[0025] The formula of Czapek’s medium is composed of 30 g sucrose, 3 g sodium nitrate, 1.3 g dipotassium hydrogen phosphate, 0.5 g magnesium sulfate, 0.5 g potassium chloride, 0.01 g ferrous sulfate, 3 g yeast extract, and 1000 ml water.

[0026] 3) Purification of swainsonine from Rhizoctonia le...

Embodiment 2

[0031] Example 2: According to the technical scheme of the present invention, the process of purifying swainsonine is carried out in the following steps:

[0032] 1) Preservation of Rhizoctonia legumes 7-3: Inoculate the self-isolated Rhizoctonia legumes 7-3 in PDA medium, store in a refrigerator at 4°C, and pass down once every 25 days;

[0033] The formula of PDA medium is: 1000g peeled potatoes, 75g agar, 100g glucose, and 5000ml water;

[0034] 2) Rhizoctonia legumes 7-3 inoculation, culture and mycelium collection: In a sterile state, inoculate 7-3 strains in Czapek's medium for biological fermentation, and cultivate for 2 weeks with aeration at 27°C to collect the hyphae Body, dry, set aside;

[0035] The formula of Czapek’s medium is composed of 150 g sucrose, 15 g sodium nitrate, 6.5 g dipotassium hydrogen phosphate, 2.5 g magnesium sulfate, 2.5 g potassium chloride, 0.05 g ferrous sulfate, 15 g yeast extract, and 5000 ml water.

[0036] 3) Purification of swainsonine from...

Embodiment 3

[0041] Example 3: According to the technical scheme of the present invention, the process of purifying swainsonine is carried out according to the following steps:

[0042] 1) Preservation of Rhizoctonia legumes 7-3: Inoculate the self-isolated Rhizoctonia legumes 7-3 PDA medium, store in a refrigerator at 4°C, and passage once every 20 days to 30 days;

[0043] The formula of PDA medium is: 2000g peeled potatoes, 150g agar, 200g glucose, and 10000ml water;

[0044] 2) Rhizoctonia legumes 7-3 inoculation, culture and mycelium collection: In a sterile state, inoculate 7-3 strains in Czapek's medium for biological fermentation, culture at 26°C with aeration for 2 weeks, and collect the hyphae Body, dry, set aside;

[0045]The formula of Czapek’s medium is as follows: sucrose 300g, sodium nitrate 30g, dipotassium hydrogen phosphate 13g, magnesium sulfate 5g, potassium chloride 5g, ferrous sulfate 0.1g, yeast extract 30g, and water 10000ml.

[0046] 3) Purification of swainsonine from...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com