Diffusion film for diffusion board

A technology of diffusion film and diffusion plate, which is applied in the field of diffusion film, can solve the problems of time-consuming process and other problems, and achieve the effects of accelerating the formation rate, avoiding polymerization reaction, and increasing toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] A diffusion film for a diffusion plate according to a preferred embodiment of the present invention will be described below with reference to related drawings.

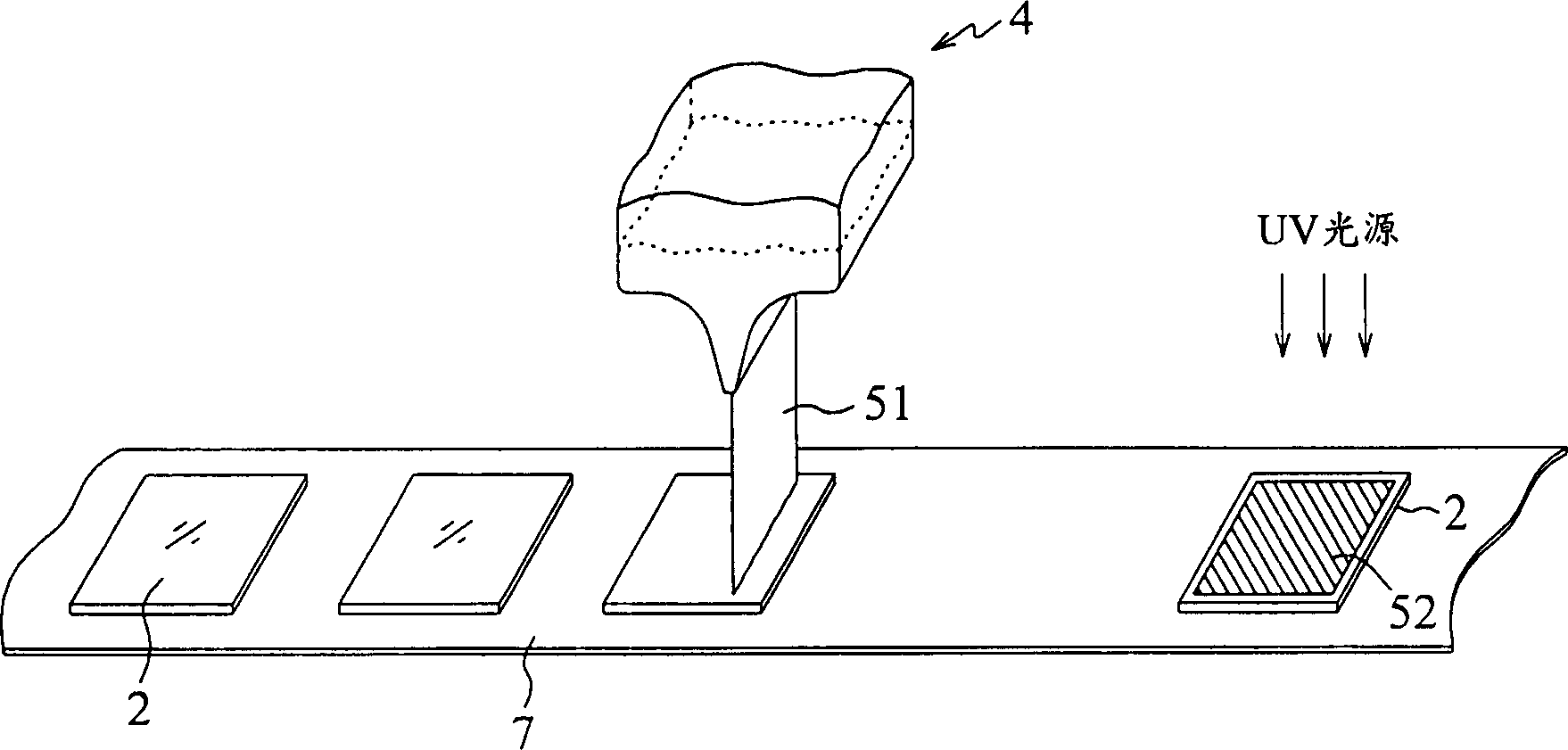

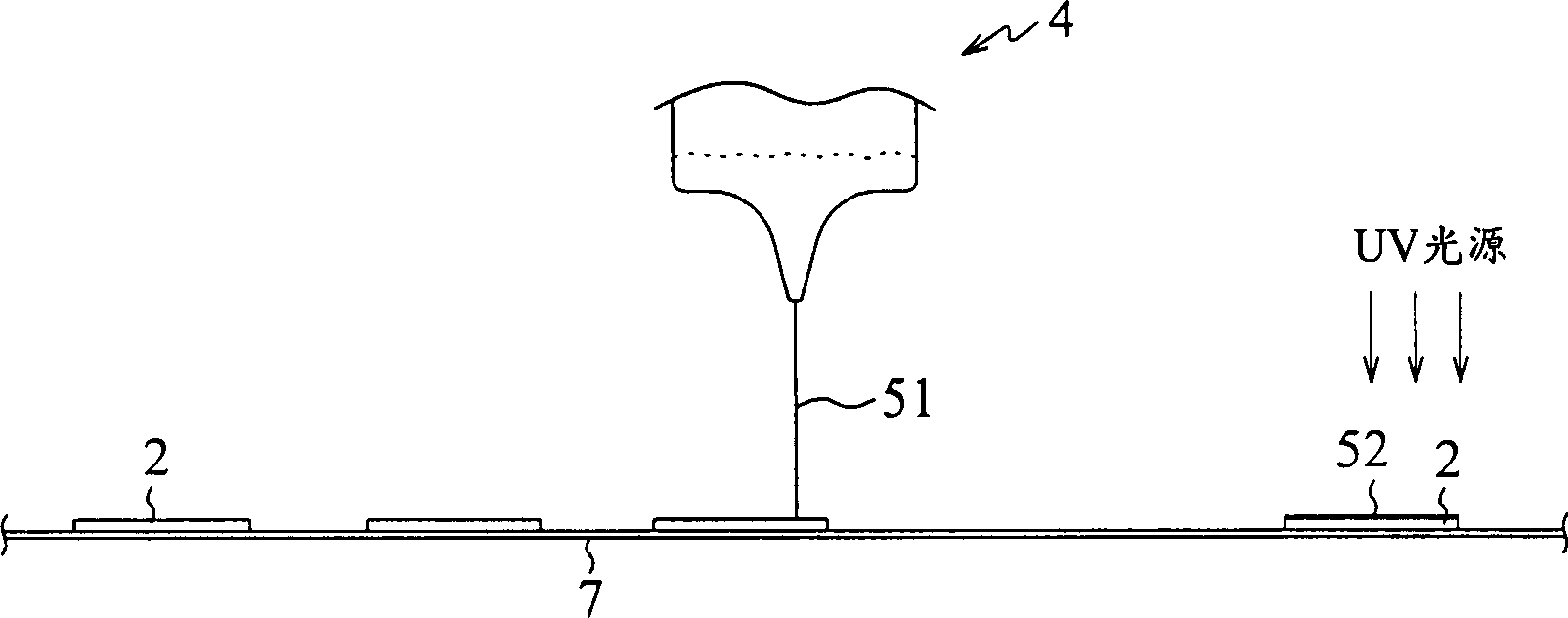

[0014] The diffusion film used in the diffusion plate of the present invention is formed by curtain coating and photocuring. Such as figure 1 and figure 2 As shown, a transparent substrate 2 is provided, such as an acrylic (Aerylic) plate, polycarbonate (PC) plate, or strengthened glass, etc., on a conveyor belt 7, so that the substrate 2 can be conveyed sequentially; When the substrate 2 reaches the stage of coating the diffusion material 51, the liquid diffusion material 51 flows out from a container 4 in the form of a waterfall, so that the diffusion material 51 can be evenly coated on the substrate 2. This coating method is called a waterfall. curtain coating method.

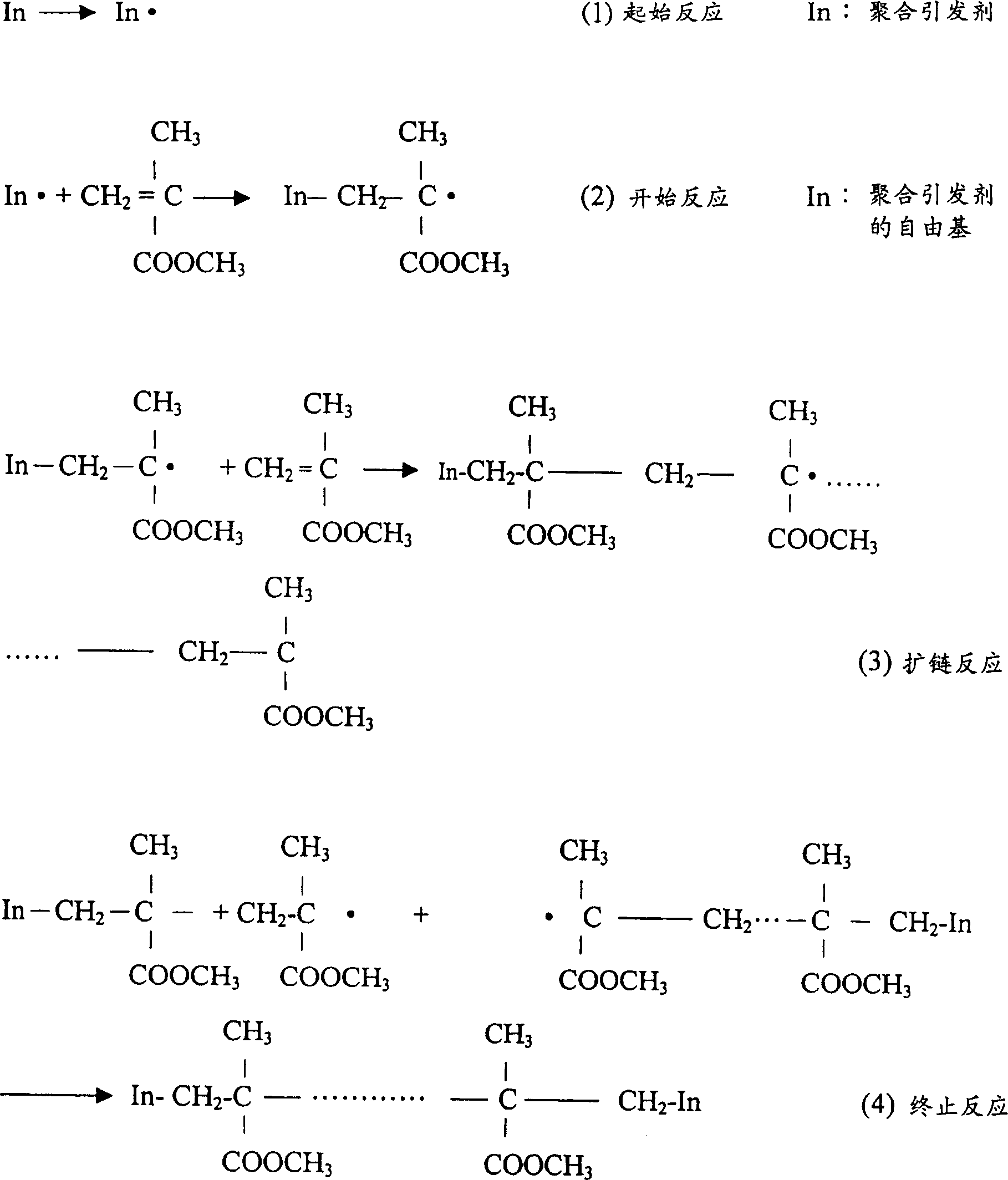

[0015] In this embodiment, the diffusion material 51 mainly includes acrylate, a photoinitiator (Photoinitiator), a diffusion powder (di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com