Flame-retardant emulsion and preparation method and application thereof

A flame-retardant, emulsion technology, applied in the field of flame-retardant materials, can solve problems such as high equipment requirements, complicated preparation process, and difficult waste liquid treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

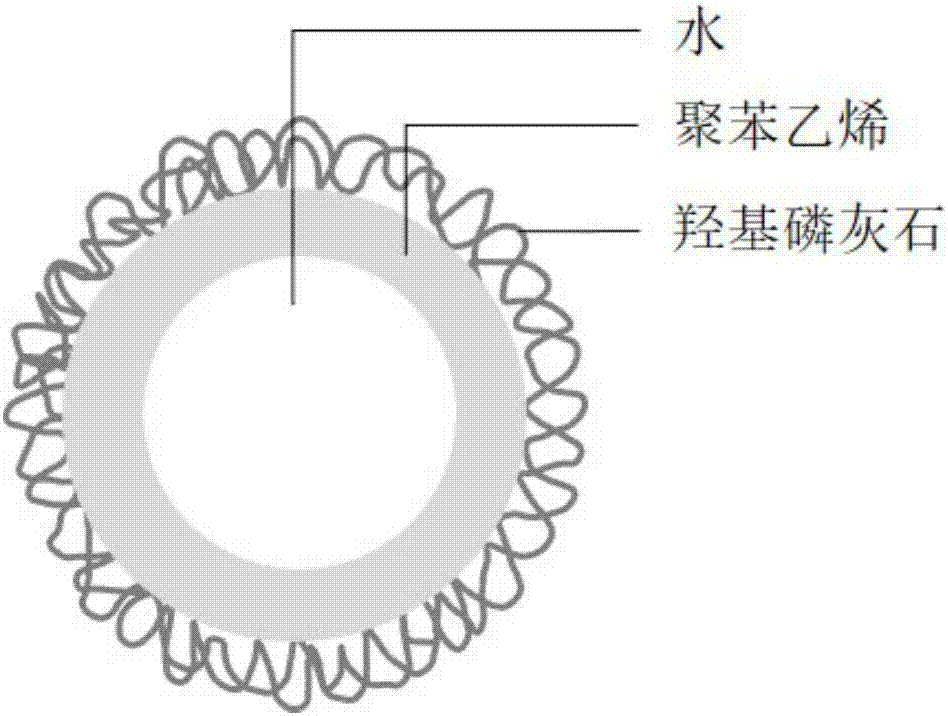

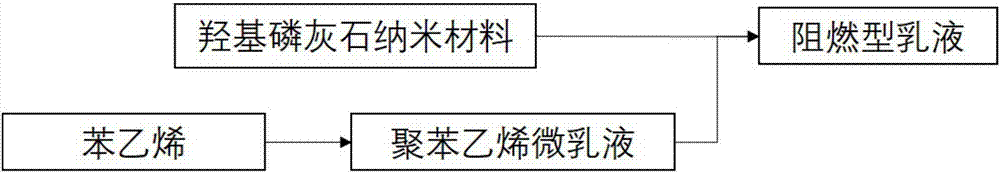

[0029] The preparation process of a kind of flame-retardant emulsion of the present invention is as follows: figure 2 shown.

[0030] Each starting material in the preparation method of the present invention can be purchased from the market or prepared according to the prior art methods. The nano-hydroxyapatite of two-dimensional network structure refers to the prior art (H.Li, D.B.Wu, J.Wu, L.Y.Dong, Y.J.Zhu, X.L.Hu, "Flexible, High-Wettability and Fire-Resistant Separators Based on Hydroxyapatite Nanowires for Advanced Lithium-Ion Batteries", Advanced Materials, 2017) and prepared through further improvement, the specific steps are described in the examples. The hydroxyapatite purchased in the market is generally spherical, rod-shaped or needle-shaped, and does not have a network structure; while the nano-hydroxyapatite prepared by the present invention has a two-dimensional network structure.

[0031] In the experimental operation of the examples, the room temperature is...

Embodiment 1

[0045] A flame retardant emulsion, its preparation method is as follows:

[0046] (1) Mix disodium hydrogen phosphate, calcium chloride and water in a mass ratio of 1:5:500, heat at 100°C for 48 hours, wash with water until neutral, and dry at 105°C to obtain a two-dimensional network Structure of the nanomaterial hydroxyapatite.

[0047] (2) Ammonium persulfate, styrene and water are mixed according to the mass ratio of 1:100:200, and at room temperature (25 ± 1° C.), obtain a polystyrene microemulsion after stirring and reacting at 100 r / min for 30 min; The hydroxyapatite and polystyrene microsphere emulsions prepared in 1) were mixed according to the mass ratio of 10% and 90%, and stirred at 500r / min for 60min at 30°C to complete the assembly process.

[0048] Apply the prepared flame-retardant emulsion to paper (quantitative 80g / m2) at room temperature (about 25°C) 2 The upper and lower surfaces of the A4 copy paper, the same below), the limiting oxygen index (LOI) was m...

Embodiment 2

[0050] A flame retardant emulsion, its preparation method is as follows:

[0051] (1) Mix disodium hydrogen phosphate, calcium chloride and water in a mass ratio of 1:1:200, heat at 300°C for 12 hours, wash with water until neutral, and dry at 105°C to obtain a two-dimensional network Structure of the nanomaterial hydroxyapatite.

[0052] (2) Azobisisobutyronitrile, styrene and water were mixed according to the mass ratio of 1:50:50, and stirred and reacted at 2000r / min for 5min at room temperature (25±1°C) to obtain a polystyrene microemulsion. Mix the hydroxyapatite and polystyrene microsphere emulsion prepared in step (1) according to the mass ratio of 20% and 80%, and stir at 50° C. at 5000 r / min for 20 minutes to complete the assembly process.

[0053] Apply the prepared flame-retardant emulsion to paper (quantitative 80g / m2) at room temperature (about 25°C) 2 The upper and lower surfaces of the A4 copy paper, the same below), the limiting oxygen index (LOI) was measure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com