Implant with bioactive coating and manufacturing method thereof

A manufacturing method and bioactive technology, applied in coatings, drug delivery, pharmaceutical formulations, etc., can solve problems such as poor bonding strength between coatings and substrates, increased tendency and degree, and reduced biological activity, so as to avoid peeling and cracking, Improve the compactness and maintain the effect of stable degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

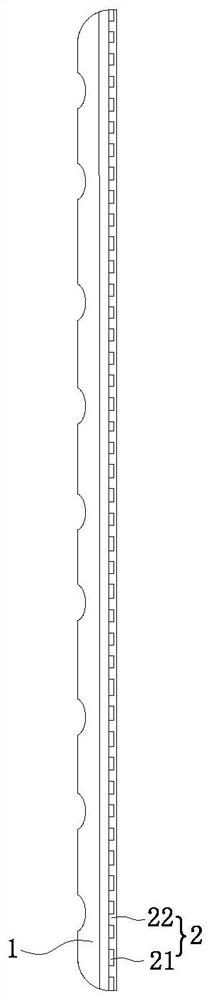

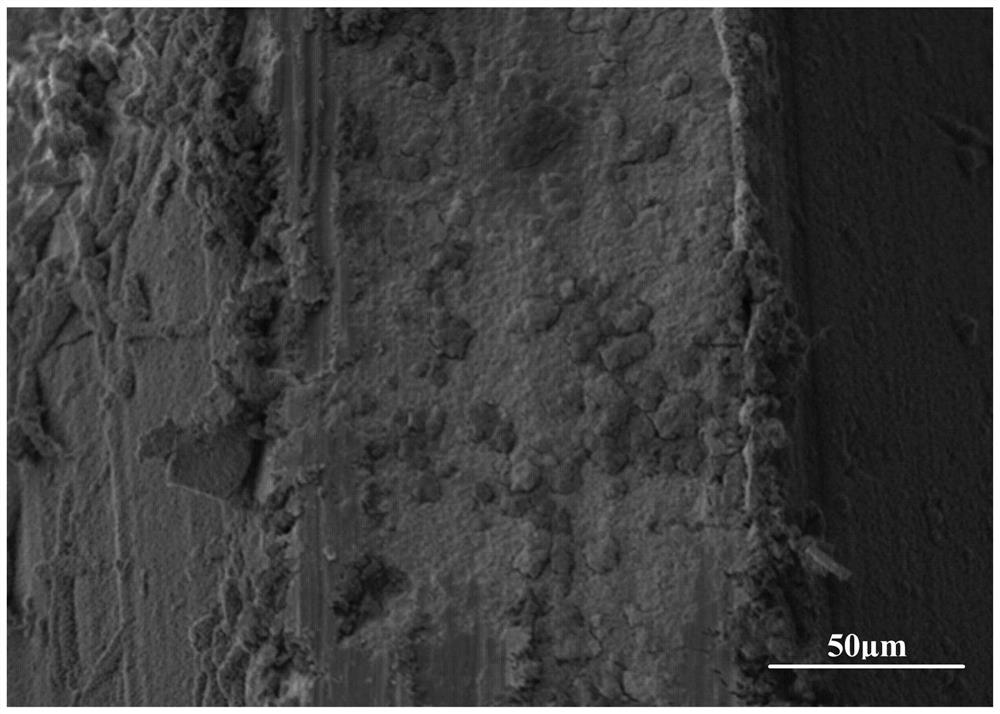

[0065] The present invention provides an implant with a bioactive coating, comprising a metal implant and a bioactive coating formed on the surface of the metal implant, the bioactive coating comprising textured discontinuous bioactive Glass coating and carbonated hydroxyapatite layer overlying the textured discontinuous bioactive glass coating.

[0066] refer to figure 1 , take the metal implant as the locking plate as an example, the locking plate 1 has a bioactive coating 2 on the surface of one side that fits the bone tissue, and the bioactive coating 2 includes textured discontinuous bioactive glass Coating 21 and carbonated hydroxyapatite layer 22 overlying the textured discontinuous bioactive glass coating.

[0067] The textured discontinuous bioactive glass coating here refers to that the textured bioactive glass coating is arranged on the surface of the metal implant in a discontinuous manner, that is, the bioactive glass coating has multiple bioactive glass coatings...

Embodiment 2

[0080] The present invention also provides a method for preparing the implant with the bioactive coating provided in Example 1, comprising the following steps:

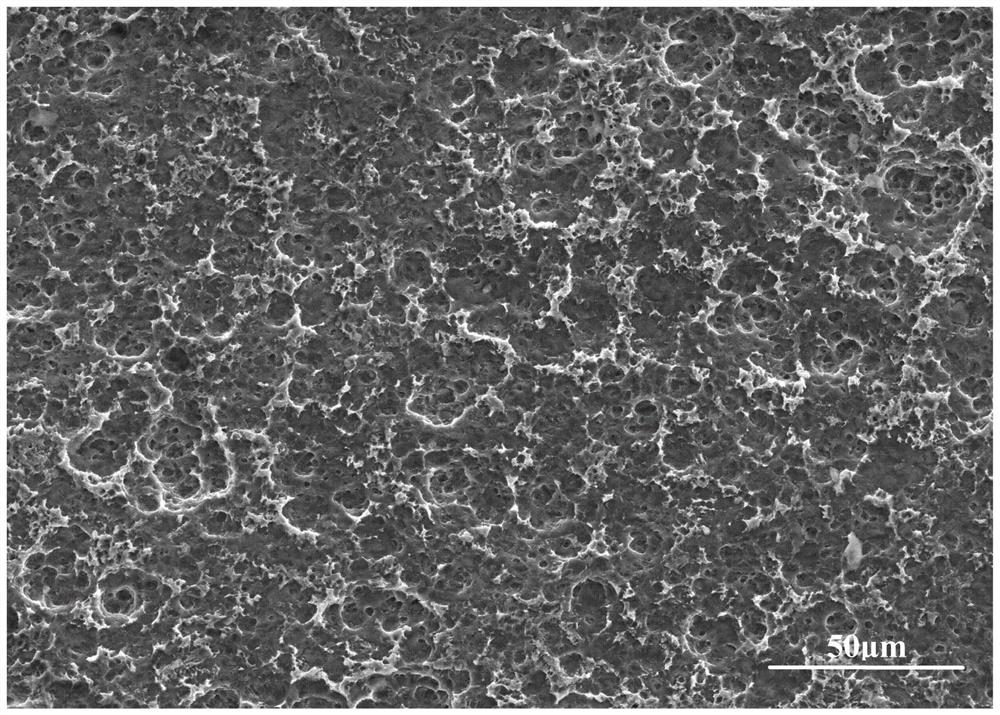

[0081] S1. Sandblasting and acid etching treatment: the metal implant is subjected to acid washing treatment, and then the clean metal implant is subjected to multi-level micro-nano treatment to form a multi-level micro-nano level on the surface of the clean metal implant. hole structure.

[0082] The metal implants were cleaned before sandblasting and acid etching. The metal implants were first cleaned with acetone and deionized water, and then cleaned in H 3 PO 4 , HNO 3 , HF mixed acid solution soaked for 10min, then washed with deionized water and absolute ethanol respectively, dried in a 50 ℃ oven for use.

[0083] The multi-level micro-nano-scale hole structure on the surface of the metal implant is realized by sandblasting and acid etching in sequence. Among them, the sandblasting treatment can use ceramic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com