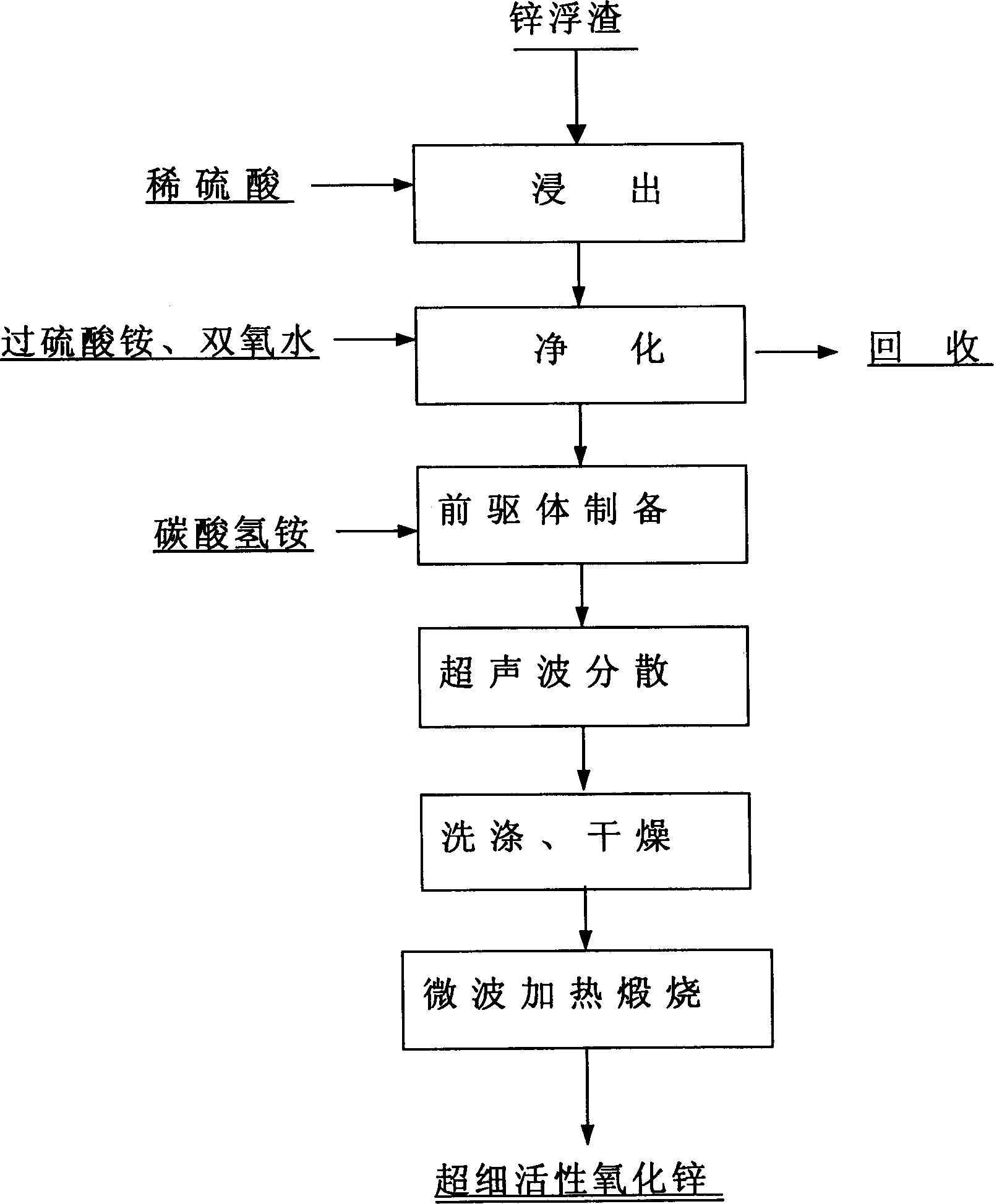

Preparation of active zinc oxide from zinc dross by ultrasonic-microwave process

A technology of active zinc oxide and zinc scum, applied in the direction of improving the process efficiency, can solve the problems of high raw material price, high process energy consumption, limiting the wide application of ultra-fine active zinc oxide, etc., and achieve the effect of shortening the calcination time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment one: 1. raw material

[0026] Zinc dross is taken from a zinc factory, its composition and weight percentage: Zn 75-80%, Fe0.5-0.7%, S 1.2-2.0%, Cd (trace), Pb 0.087%, SiO 2 0.31%, As 0.088%, Sb 0.0023%, Co 0.0006%, Mn 0.84%, CI 0.5-2.0%. 2. Zinc dross leaching

[0027] Use dilute sulfuric acid (1.4mol / L) to leach 1000g of zinc scum. The leaching conditions are as follows: the temperature is normal temperature, leaching and stirring for 50min, leaching for 2h, and the solid-liquid ratio is 1:6. Under this condition, the leaching rate of zinc is 92.5%. The leaching solution is filtered to remove SiO in the raw material 2 . 3. Zinc sulfate solution purification

[0028] The purification of zinc sulfate solution is divided into three stages of purification, the first stage removes manganese; the second stage removes iron and arsenic; the third stage removes impurities such as lead, cadmium, and cobalt. 3.1 Manganese removal

[0029] Ammonium persulfate i...

Embodiment 2

[0034] Embodiment two: 1. raw material

[0035] Zinc dross is taken from a zinc factory, its composition and weight percentage: Zn 74-84%, Fe0.5-0.68%, S 1.6-2.0%, Cd (trace), Pb 0.08%, SiO 2 0.30%, As 0.078%, Sb 0.004%, Co 0.0008%, Mn 0.54%, CI 0.8-2.2%. 2. Zinc dross leaching

[0036] Use dilute sulfuric acid (1.8mol / L) to leach 2000g of zinc scum. The leaching conditions are as follows: the temperature is normal temperature, the leaching is stirred for 60min, the leaching is 1.8h, and the solid-liquid ratio is 1:8. Under this condition, the leaching rate of zinc is 93.0%. The leaching solution is filtered to remove SiO in the raw material 2 . 3. Zinc sulfate solution purification 3.1 Manganese removal

[0037] Ammonium persulfate is used to directly remove manganese in zinc sulfate solution. The optimal process conditions for manganese removal are: temperature 93°C, pH value 5.4, reaction 3.5h, manganese removal rate over 99.90%, manganese content 0.00014g / L. 3.2 Iro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com