Carbon-bearing platinum-iron alloy electrocatalyst for PEM electrolyte fuel cell and its preparing method

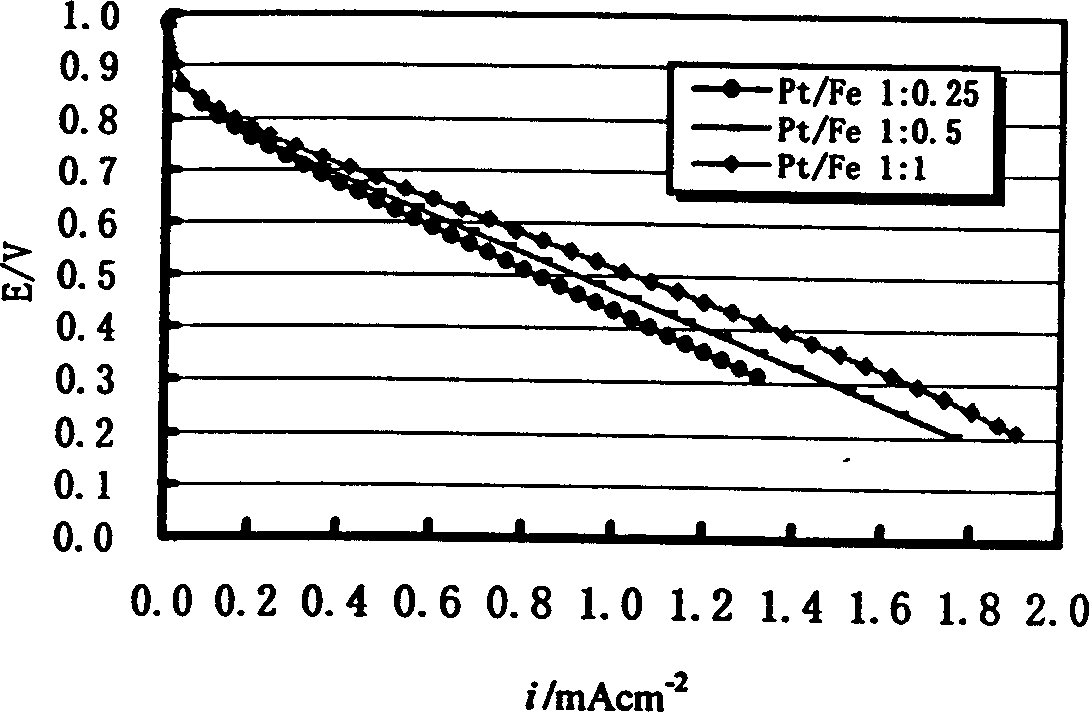

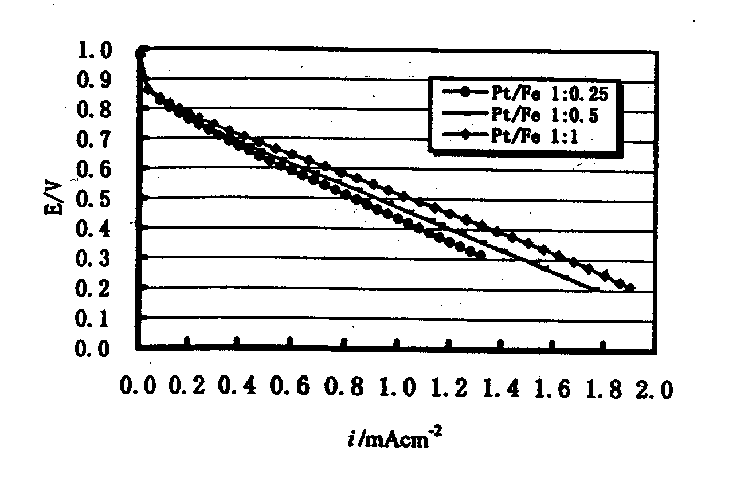

A technology of proton exchange membrane and electrocatalyst, which is applied in the direction of battery electrodes, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc. It can solve the problems of slow discharge, battery energy loss, large polarization overpotential, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Boil Vulcan.XC-72 activated carbon carrier with concentrated nitric acid for 2 hours, wash with distilled water until neutral, filter, discard the filtrate, dry at 100°C, place in a tube furnace, and heat at 500°C for 1 hour under an inert atmosphere. Take 0.60 g of the carbon powder in a small beaker, add distilled water at a liquid-solid ratio of 1:40, and vibrate ultrasonically for 30 minutes to obtain reactant A.

[0030] Take the concentration as 5.00g / dm -3 80ml of metal platinum solution dissolved in aqua regia, dilute with distilled water to a concentration of 2g / dm -3 , add 1% Qutong X-100 surfactant 5ml, add 3g sodium bisulfite (NaHSO3) while stirring, react for 1 hour, and the pH of the solution is about 2.7 at this time, to obtain solution B.

[0031] Dilute B to 200ml with distilled water, add 20ml of 30% H 2 o 2 , the pH value of the solution in the reaction system was adjusted to 7 with 10% NaOH solution to obtain solution C.

[0032] Mix reactants A ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com