Method for forming gratings by laser direct writing device

A technology of circular grating and laser beam, which is applied in the field of circular grating and manufacturing measurement length, which can solve the problems of many manufacturing processes, unfavorable indexing measurement, and poor linearity, so as to improve work efficiency and reliability, simplify hardware processes, and improve the grid line edge. clear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

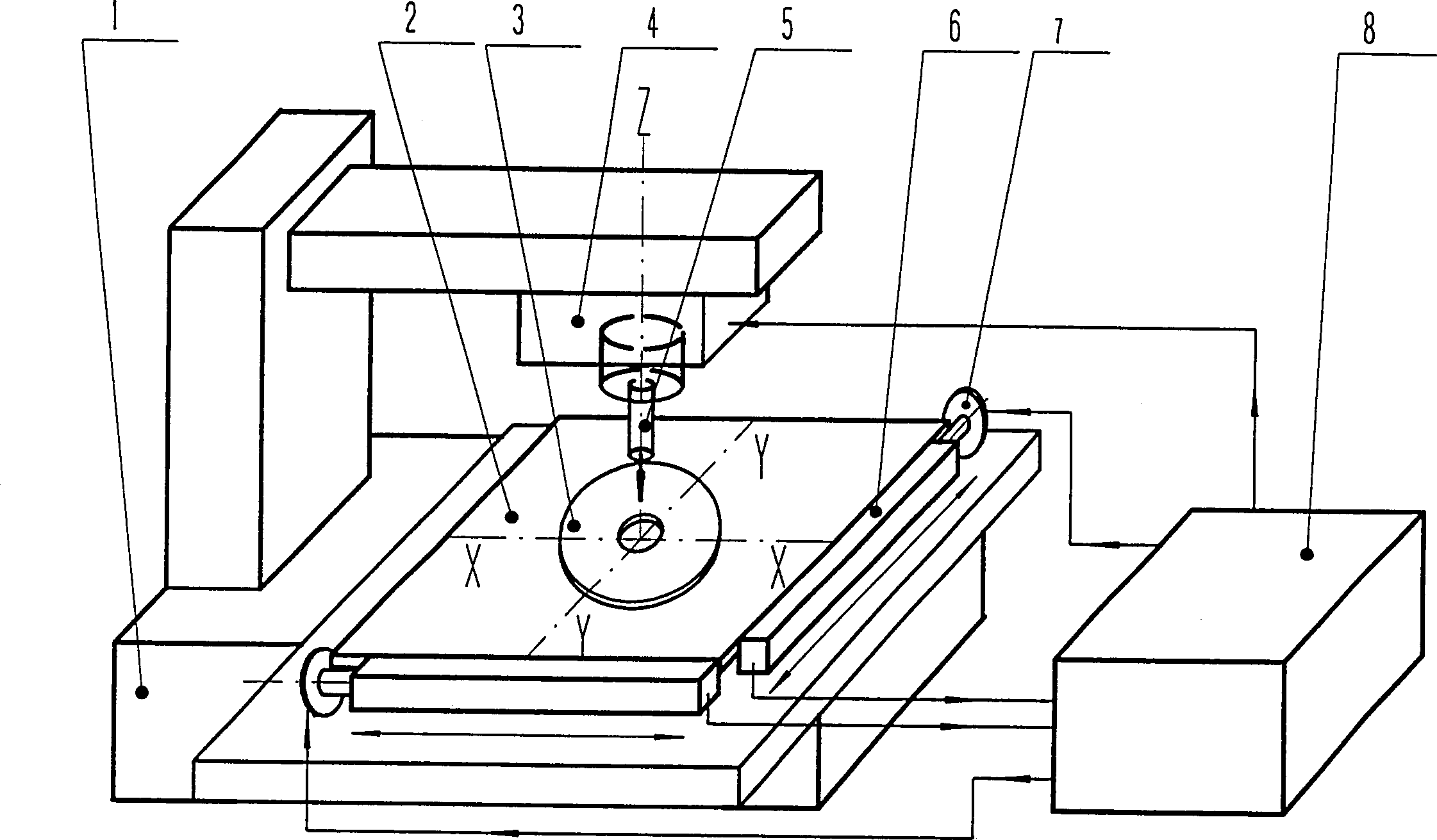

[0027] The present invention will be described below in detail by taking a circular grating as an example according to the accompanying drawings, and this example is also suitable for manufacturing long gratings or gratings of other shapes.

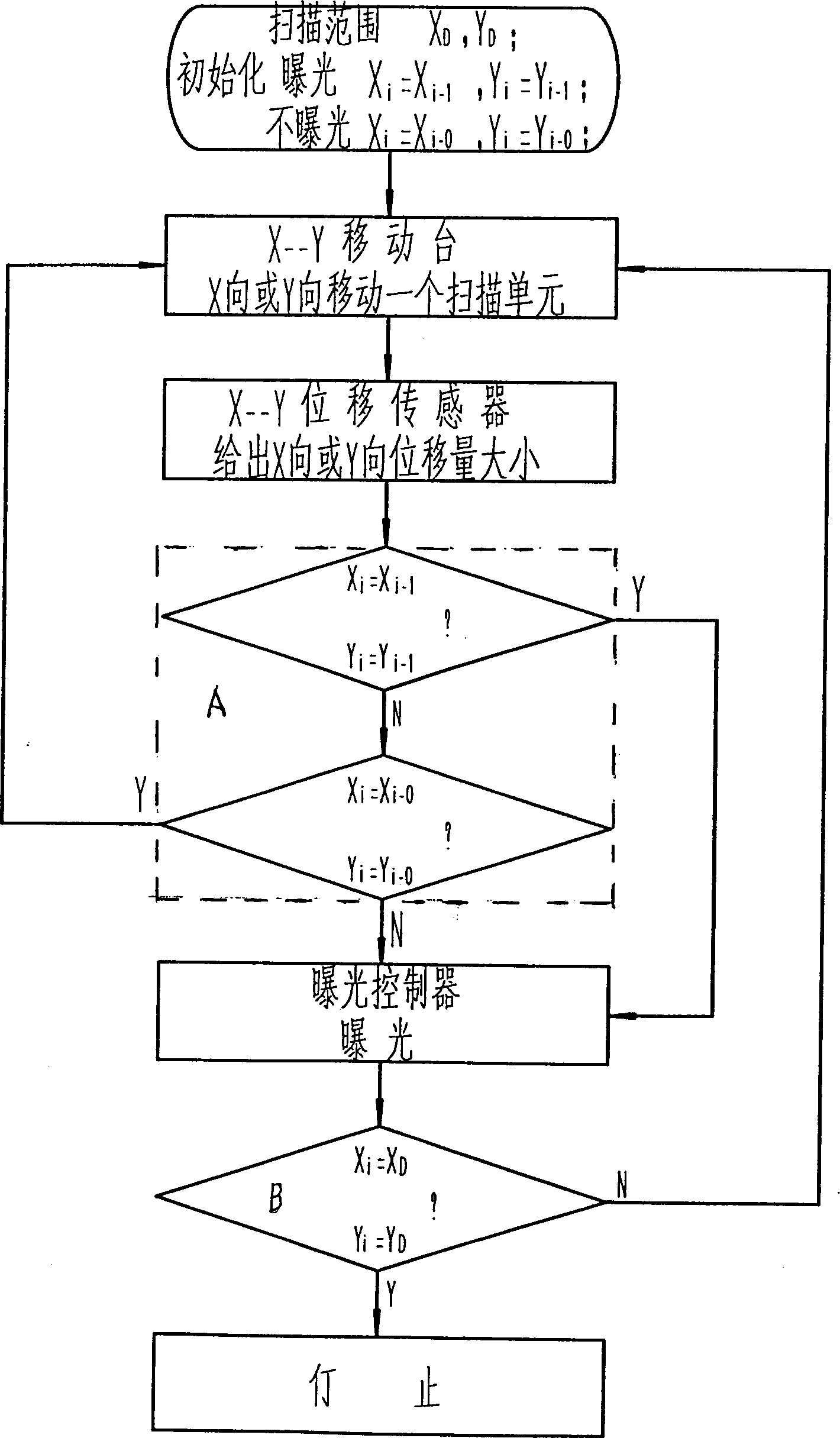

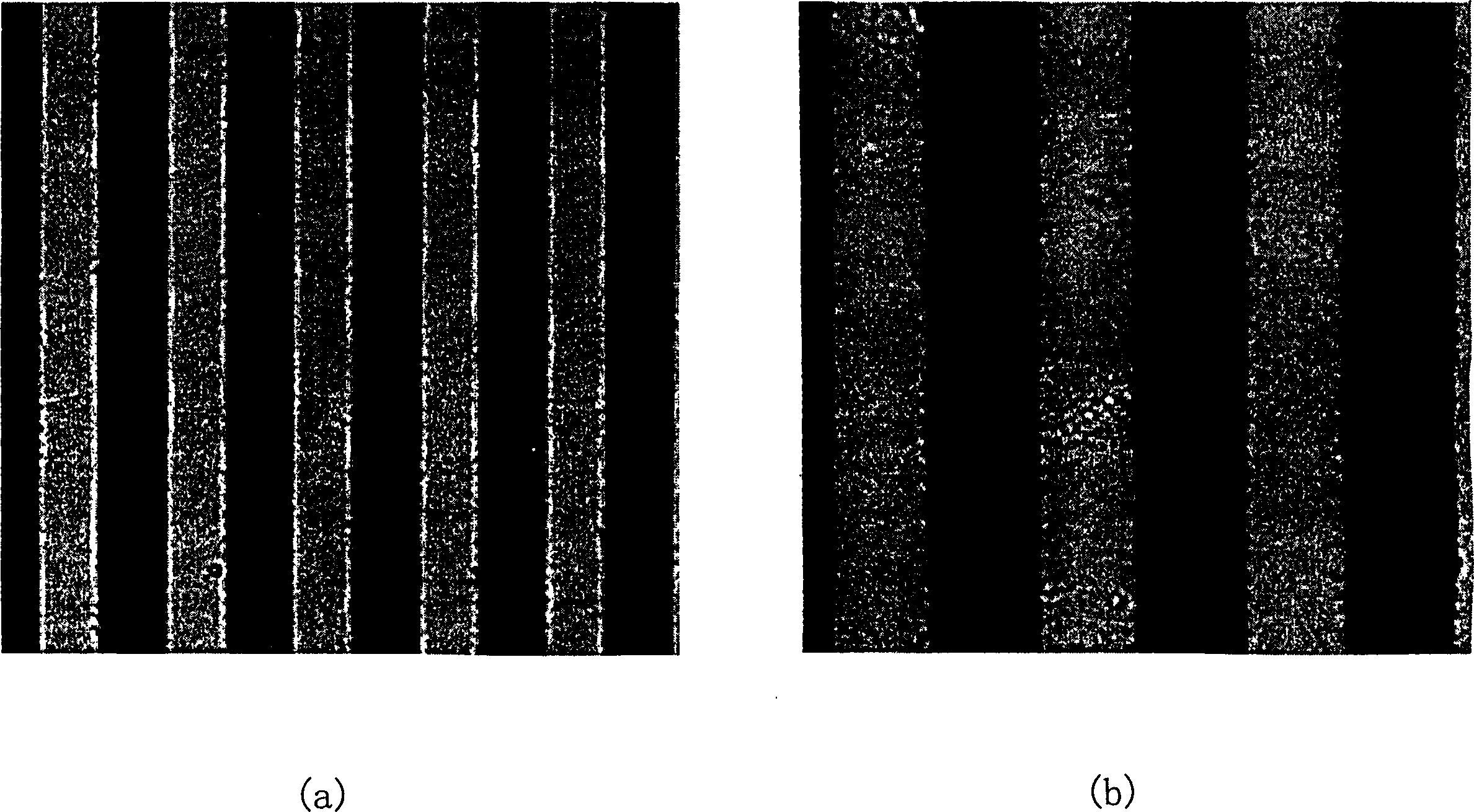

[0028] figure 1 The computer [8] in is a special-purpose computer, and various special-purpose programs are housed in it to form the computer control system. The opening or closing of the light source exposure in the exposure controller [4] is controlled by a dedicated computer. The light beam diameter of the light scanning head [5] can be adjusted, the smallest can reach 0.7 μm, and the precision is 0.1 μm. The diameter of the scanning light is related to the processing quality and efficiency. If the scanning light is too thick, the edge quality of the grating line will be reduced; if the scanning light is too thin, it will improve the quality of the line, but it will increase the time for manufacturing the grating. Therefore, it is g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com