Supported tungstic acid catalyst for synthesizing glutaraldehyde and its producing method

A technology for synthesizing glutaraldehyde and supporting type, applied in the chemical industry, can solve problems such as difficulty in separating homogeneous catalysts, and achieve the effects of many times of recycling, simple preparation and wide operating range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

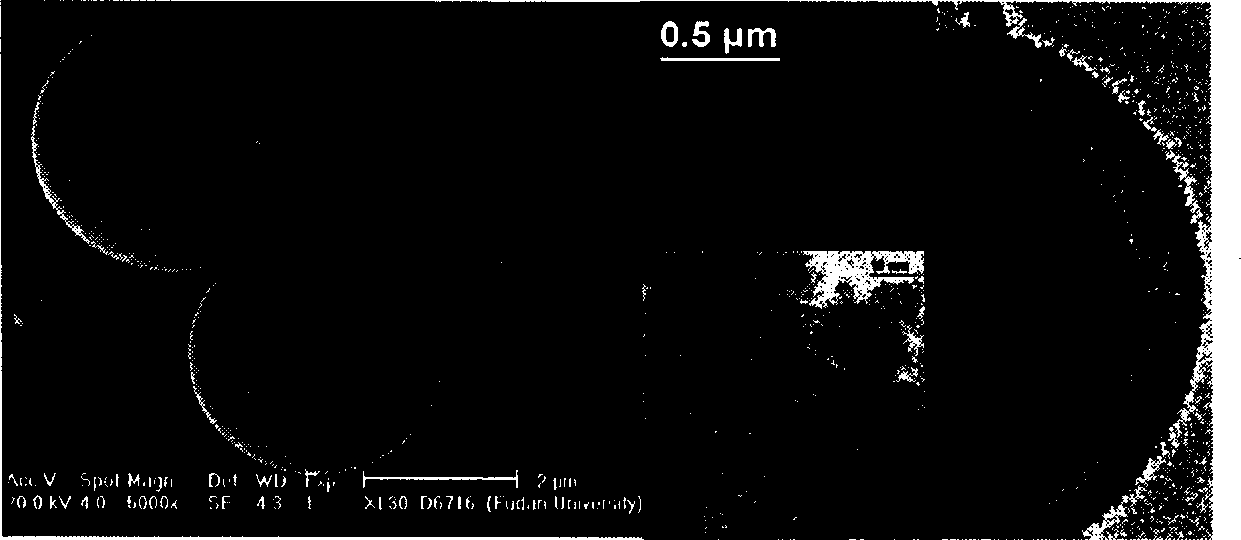

Image

Examples

Embodiment 1

[0016] Example 1: At room temperature, electromagnetic stirring, 12.5ml of 3MTiCl 4 The solution was dropped into 50ml of distilled water, stirred for 1h, 40g of urea was added, stirred for 20min, 5.0g of ammonium sulfate was added, stirred for 2h, 50ml of absolute ethanol was added, stirred for 4h. The resulting clear solution was transferred to a 200ml autoclave and sealed, crystallized at 80°C for 20h, and then taken out; filtered, washed with water, washed with ethanol, and dried under vacuum at 80°C for 24h. Available white TiO 2 Powder, marked as 1# carrier.

Embodiment 2

[0017] Example 2: At room temperature, electromagnetic stirring, 12.5ml of 3MTiCl 4 The solution was dropped into 50ml of distilled water, stirred for 1h, added 30g of urea, stirred for 20min, added 5.0g of ammonium sulfate, stirred for 2h, added 50ml of absolute ethanol, stirred for 4h. The resulting clear solution was transferred into a 200ml autoclave and sealed, crystallized at 100°C for 20h, and then taken out; filtered, washed with water, washed with ethanol, and dried under vacuum at 80°C for 24h. Available white TiO 2 Powder, marked as 2# carrier.

Embodiment 3

[0018] Example 3: In an oil bath at 95°C, weigh 0.054g of xanthosungstic acid in 15ml of deionized water, stir for 20min, add 0.89g of oxalic acid, and stir for 1h to obtain a clear solution; add 1g of carrier #1, stir and evaporate, 120 Bake at ℃ for 24h, treat at 500℃ for 3h, granulate, sieving through 40-60 mesh to obtain 3# catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com