Decolouring method of printing and dyeing waste water

A technology for printing and dyeing wastewater and wastewater, applied in chemical instruments and methods, water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of unreported oxidative degradation research, secondary pollution, high cost, and achieve good decolorization. Effect, no secondary pollution, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

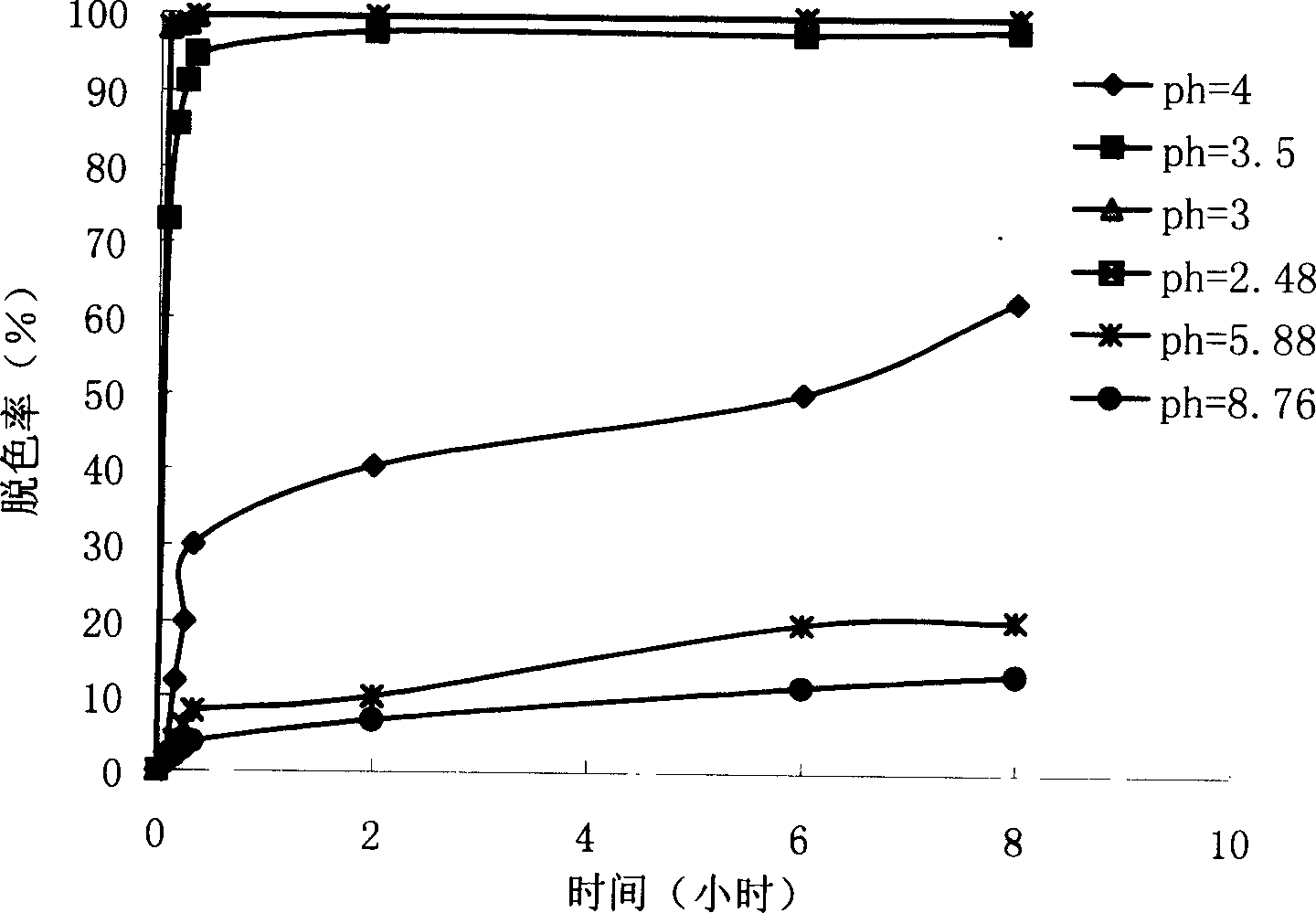

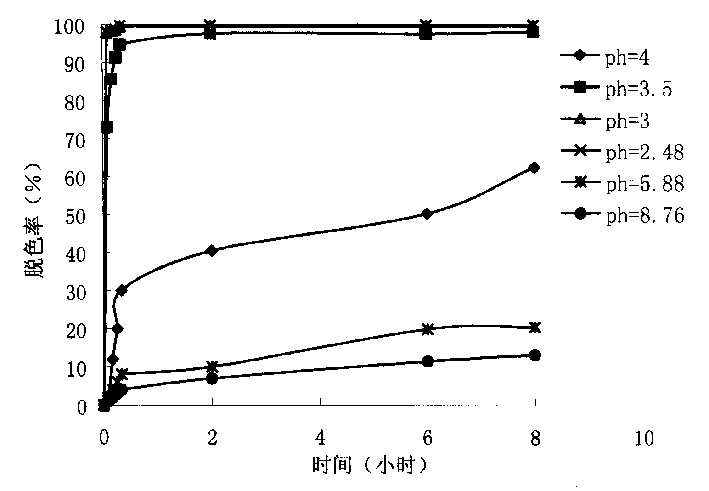

[0030] 50ml of printing and dyeing wastewater of X-3B (a common industrial dye produced by Tianjin Xinxin Dye Factory) with an initial concentration of 20mg / l was placed in a 100ml Erlenmeyer flask, and its pH value was measured with HNO 3 and NaOH adjusted to 3. The natural manganese and potassium ore is collected from Xiangtan manganese ore, washed with tap water, naturally dried, crushed and sieved to obtain 160-200 mesh manganese and potassium ore, and the dosage is 0.2g. Put the Erlenmeyer flask into a constant temperature shaker in a water bath, shake at 200r / min for half an hour at 25°C, and the decolorization rate of X-3B is almost 100%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com