Method of producing heparin oligosaccharide using heparinase

A technology of heparin oligosaccharide and heparinase, applied in the field of enzyme engineering, can solve the problems of high price, low anticoagulation, high antiproliferative activity and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

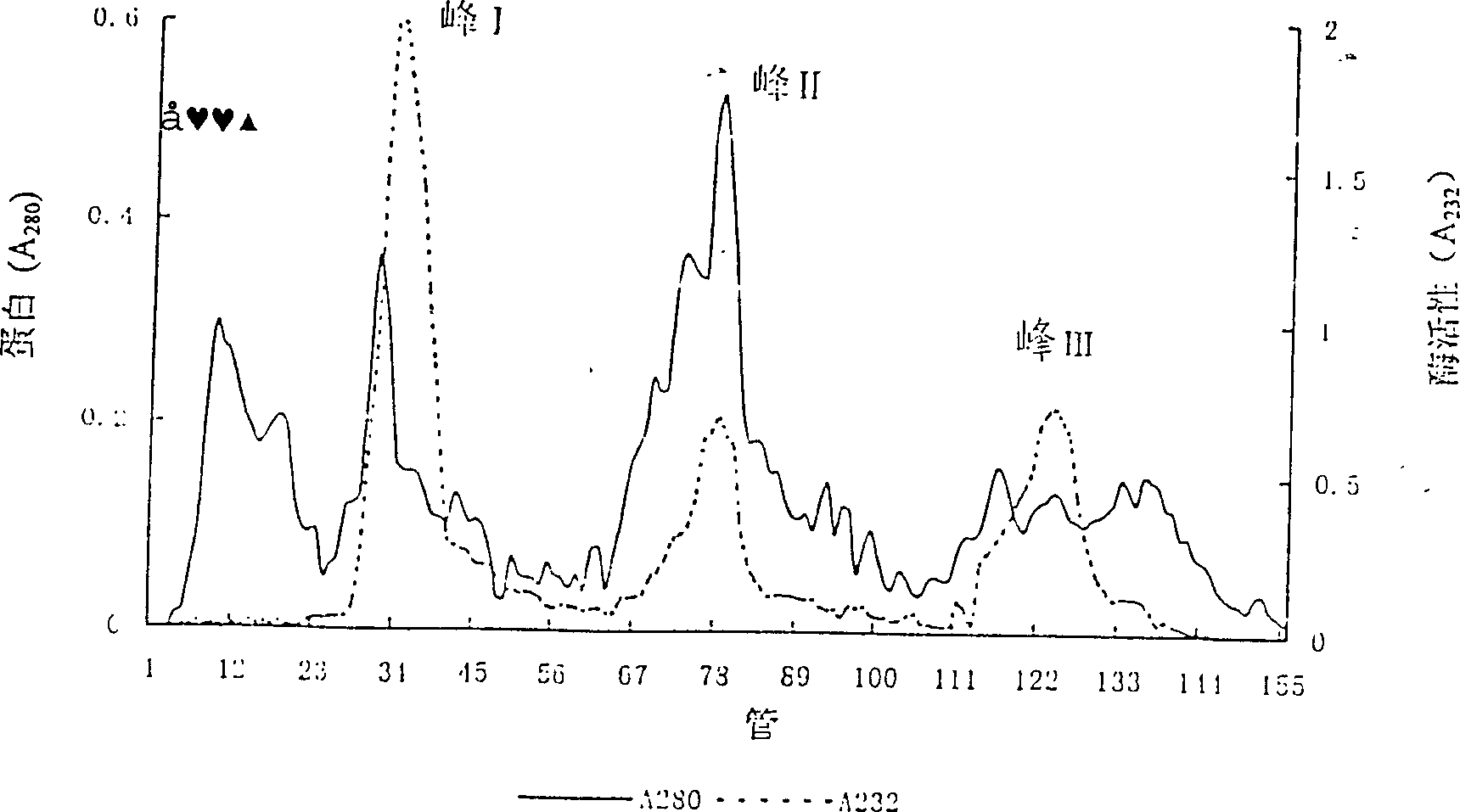

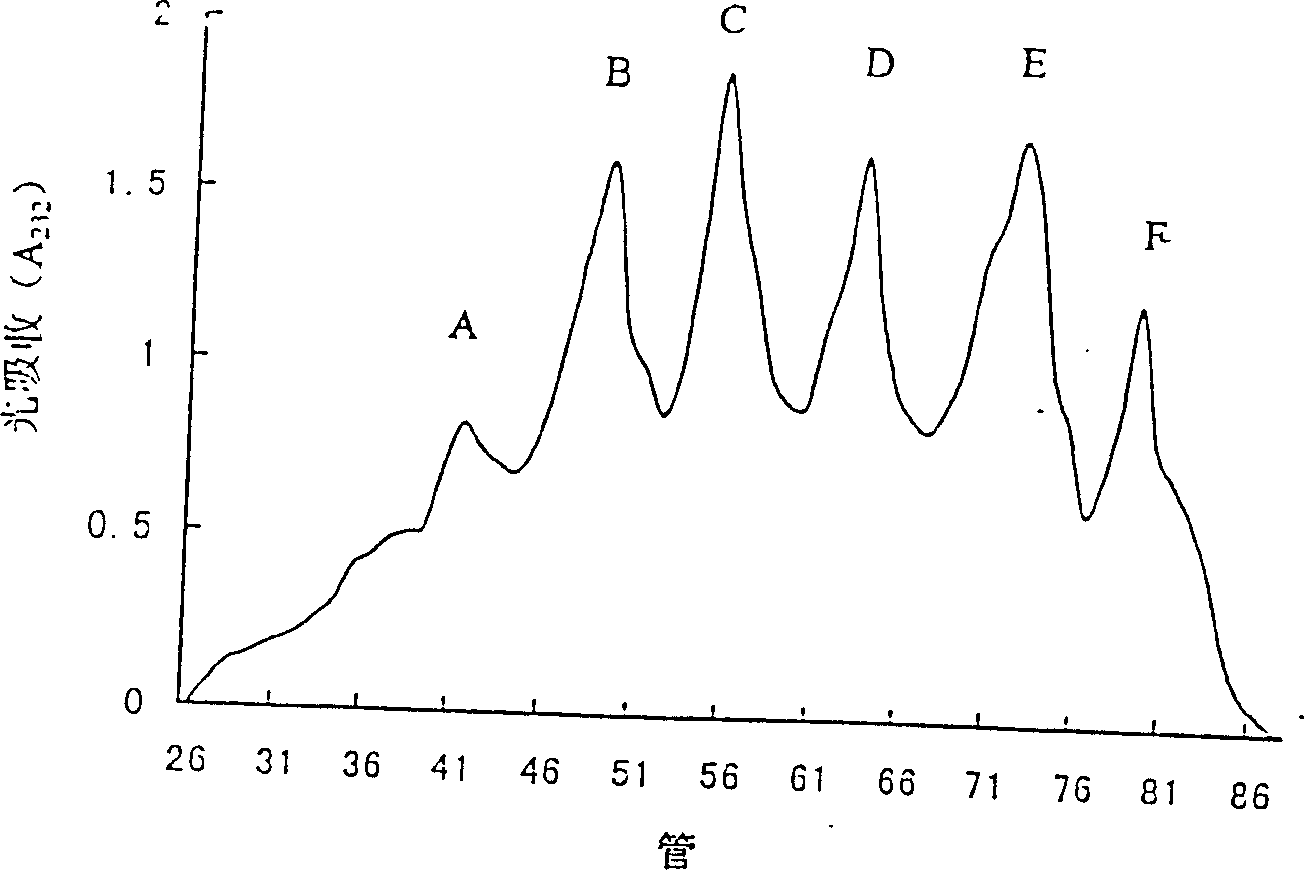

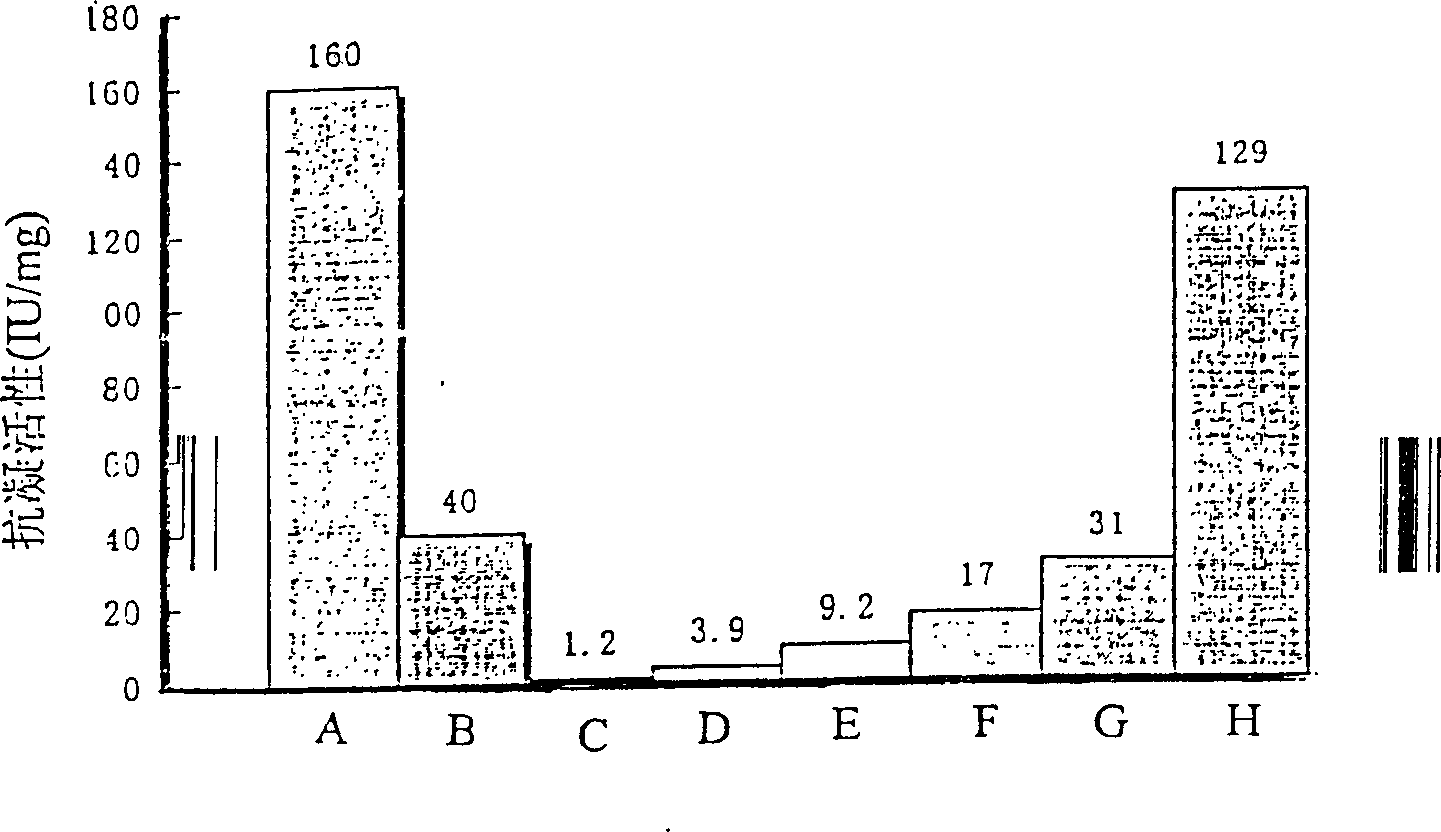

Method used

Image

Examples

Embodiment

[0019] 1. Strain cultivation and identification: Inoculate the heparanase-producing strain HC-6155 on a common beef juice slant medium, cultivate it at 30°C for 48 hours, and then insert it into a 500ml Erlenmeyer flask containing 50ml of fermentation medium , at 30 DEG C, cultivate 16 hours on a shaker at 200 rpm, then transfer to a 500ml Erlenmeyer flask filled with 50ml of the same medium at a 2% inoculum size, and cultivate for 36 hours under the same conditions. It is identified by external morphology, physiological and biochemical reaction characteristics and molecular biological methods. The external shape of the bacteria is rod-shaped, non-motile Gram-negative bacteria, which produce light purple pigments, and do not use citric acid, KNO 3 , Tween, malonic acid, etc., do not produce H 2 S gas can utilize glucose, sucrose, arabinose, and rhamnose. And according to the phylogenetic analysis results based on the 16s rRNA gene sequence, it was confirmed that the strain w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com