Polarization method for generating single polarization

A single-polarization, polarization technology, applied in prisms, nonlinear optics, instruments, etc., can solve the problems of performance differences, device performance degradation, limited application scope, etc., to achieve the effect of reducing trouble, small insertion loss, and improving coupling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

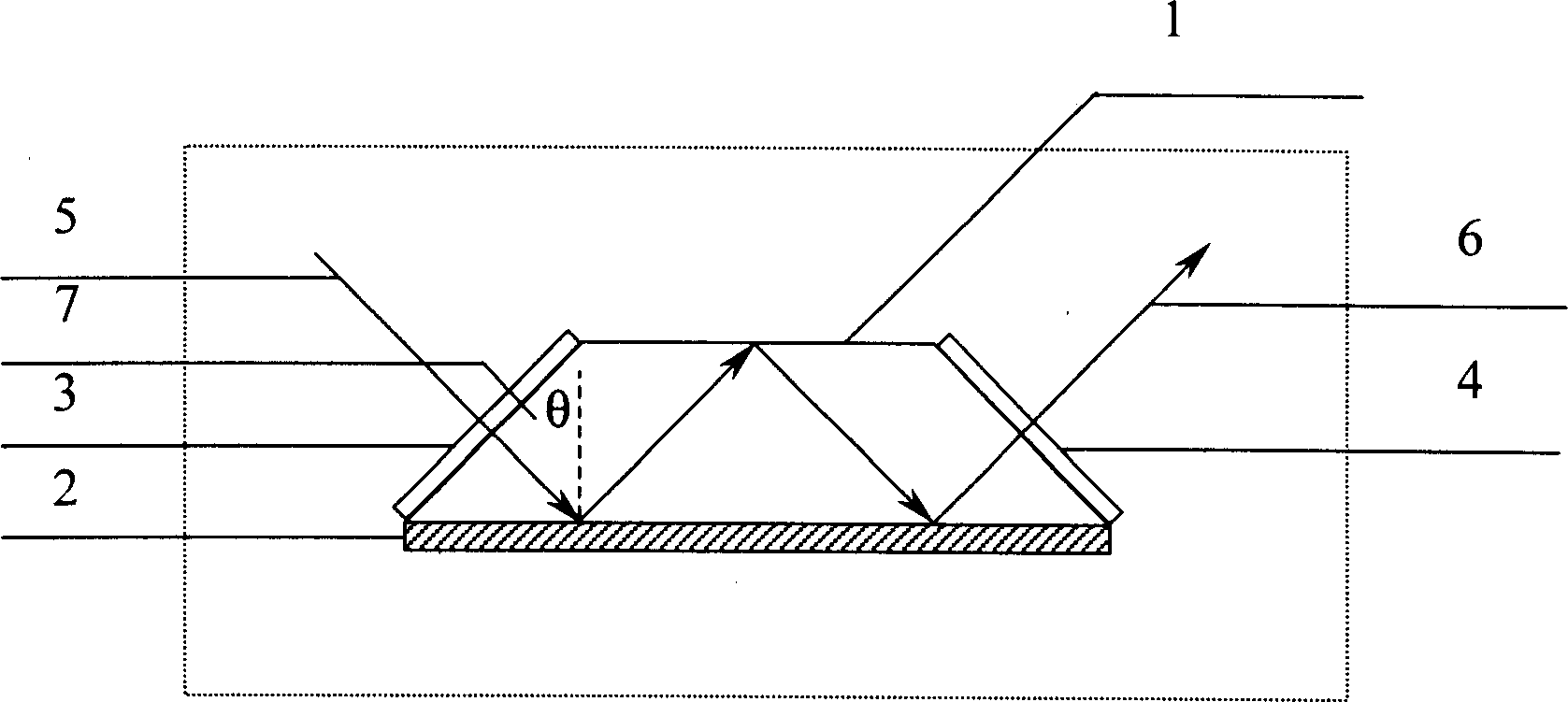

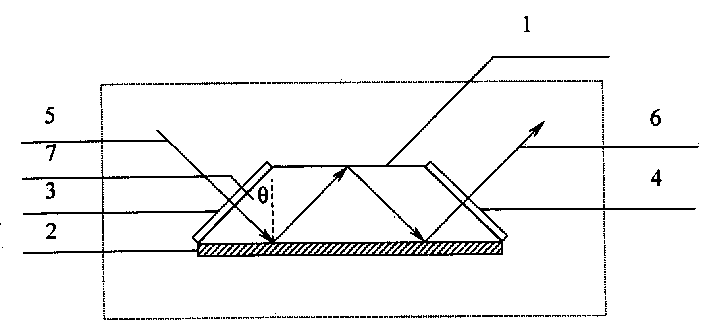

[0024] Step 1: The material of the elongated prism 1 is an elongated prism with a high refractive index (ZF6, n=1.7355). The wavelength of the incident laser 5 is 690.0nm, and the material of the metal film 2 on the bottom surface is silver (ε=-19.69+i1.24 at a wavelength of 690.0nm). The bottom angle of the elongated prism 1 is 36.3 degrees, its height is about 1cm, the length of the upper bottom surface is 2.7cm, and the length of the lower bottom surface is about 5.4cm, which meets the two reflection conditions and enables the laser beam to form two reflections on its lower bottom surface ; And a layer of anti-reflection coatings 3, 4 are vapor-deposited on the outgoing and incident surfaces of the elongated prism 1 to reduce its reflection loss.

[0025] Step 2: Make the selected incident laser beam 5 incident on the lower bottom surface of the elongated prism 1 at a certain angle of 36.3 degrees, and excite the surface plasmon waves propagating on the interface between th...

Embodiment 2

[0028] Step 1: The material of the elongated prism 1 is an elongated prism with a high refractive index (ordinary optical glass, n=1.5). The wavelength of the incident laser 5 is 560.0nm, and the material of the metal film 2 on the bottom surface is silver (ε=-11.89+i0.83 at a wavelength of 560.0nm). The bottom angle of the elongated prism 1 is 44.3 degrees, its height is about 1.2cm, the length of the upper bottom surface is 2.5cm, and the length of the lower bottom surface is about 4.9cm. reflection, and a layer of anti-reflection coatings 3 and 4 are vapor-deposited on the outgoing and incident surfaces of the elongated prism 1 to reduce its reflection loss.

[0029] Step 2: Make the selected incident laser beam 5 incident on the lower bottom surface of the elongated prism 1 at a certain angle of 44.3 degrees, and excite the surface plasmon wave propagating on the interface between the elongated prism 1 and the metal film 2 on the bottom surface. The outgoing beam 6 is rec...

Embodiment 3

[0032] Step 1: The material of the elongated prism 1 is an elongated prism with a high refractive index (ordinary optical glass, n=1.5). The incident laser wavelength is 1550.0nm, and the metal film material is gold (ε=-117.34+i10.95 at a wavelength of 1550.0nm), which is plated on the bottom surface of the elongated prism 1 by sputtering, with a thickness of 26nm. The base angle of the elongated prism 1 is 42.1 degrees, its height is about 0.8cm, the length of the upper base is 3.5cm, and the length of the lower base is about 5.3cm, which satisfies the three reflection conditions, so that the laser beam can form three reflections on its lower base, and A layer of anti-reflection coatings 3 and 4 are evaporated on the outgoing and incident surfaces of the elongated prism 1 to reduce its reflection loss.

[0033] Step 2: make the selected incident laser beam 5 incident on the lower bottom surface of the elongated prism 1 at a certain angle of 42.1 degrees, and excite the surfac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com