Plastic substrate useful for making bio-chip

A slide and plastic technology, applied in the field of plastic slides, can solve problems such as interference with biochip analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Chemically modify the surface of polystyrene slides for immobilization of proteins, or small molecule compound thing

[0036] A polystyrene material slide is used, the size of which is equivalent to a conventional glass slide used in a microarrayer or a laser scanner, and the polystyrene material slide has 2 grooves, and the depth of the grooves is 0.05 MM. The polystyrene slide was rinsed with doubly distilled water, followed by 95% ethanol (ETOH) for at least 2 hours at room temperature. The cleaned polystyrene slides were rinsed three more times with doubly distilled water and then dried. The dried polystyrene slides were immersed in 0.4% glutaraldehyde in 0.1 M phosphate buffer solution (pH 5.0) for 4 hours at room temperature, rinsed with double distilled water, and then incubated at 60 Immersion in 3M NH at °C 4 OH solution (pH 11.0) for 4 hours. The resulting polystyrene slides were treated with 100 mM 1,4-butanediol diglycidyl ether (pH 11.0) overnig...

Embodiment 2

[0038] Surface modification of polystyrene slides for DNA immobilization

[0039] The polystyrene slide with 2 grooves used in Example 1 was used, rinsed with double distilled water, and then rinsed with 95% ETOH at room temperature for at least 2 hours. The cleaned polystyrene slides were rinsed three more times with doubly distilled water and then dried. The resulting polystyrene slides were immersed in a reagent solution containing 1.12% polylysine (Sigma), 0.03% dimethyl sulfoxide (DMSO) in 50 mM carbonate for 30 minutes at room temperature Buffer, pH 9.5. The treated polystyrene slides were removed, rinsed 4 times with double distilled water, and then placed in a Laminar Flow to dry. The resulting treated polystyrene material slides can be used to fabricate DNA chips.

Embodiment 3

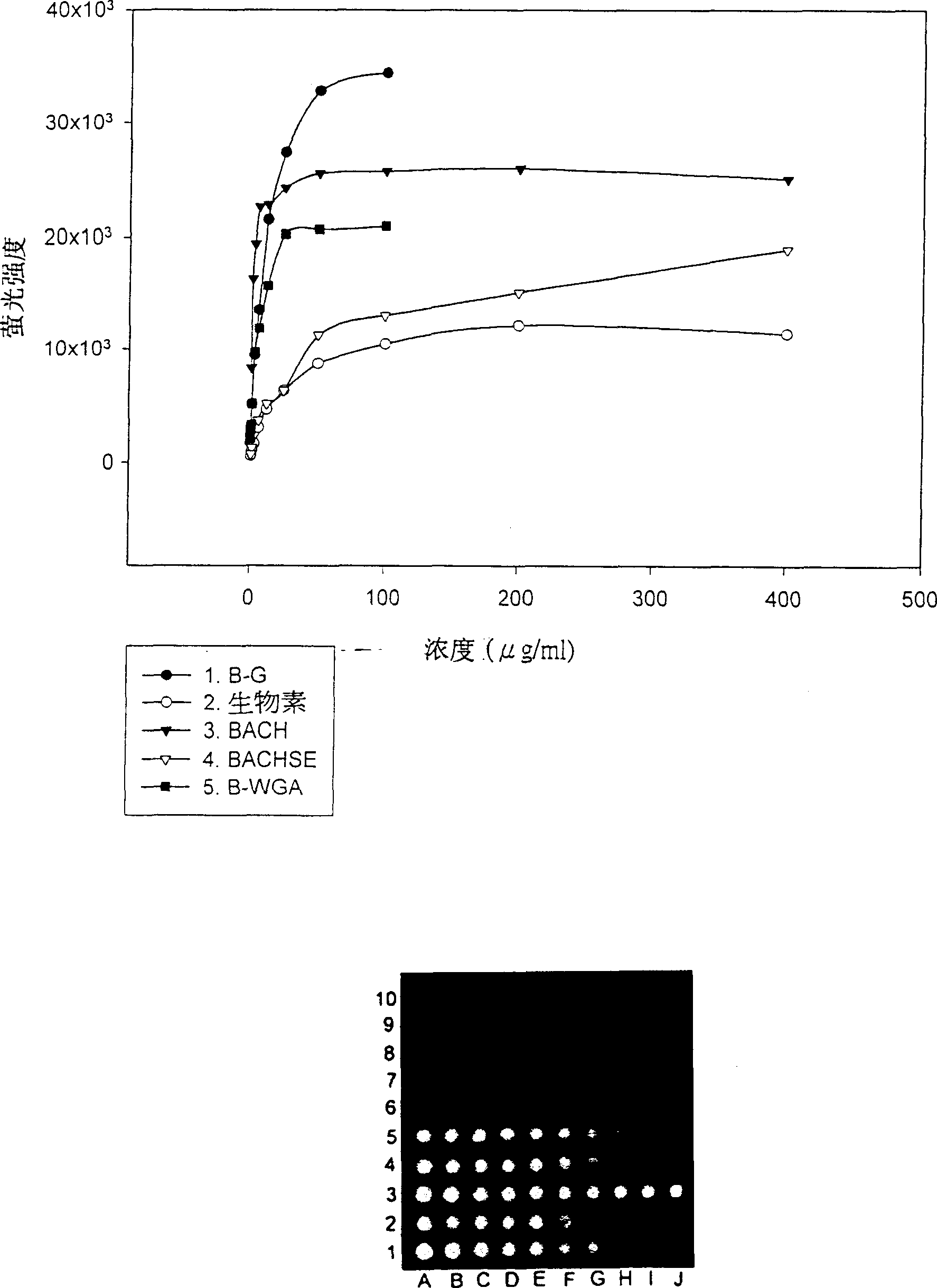

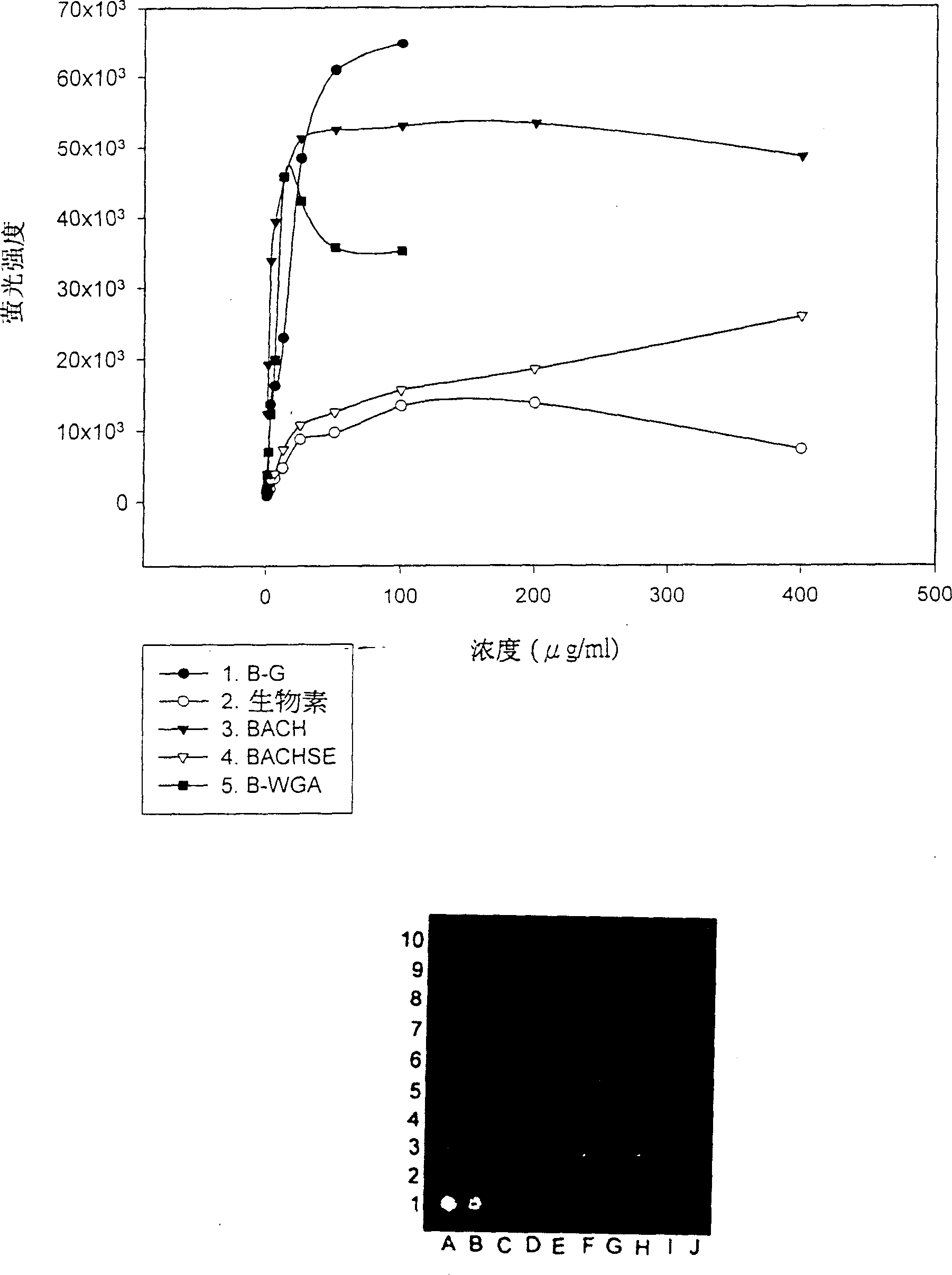

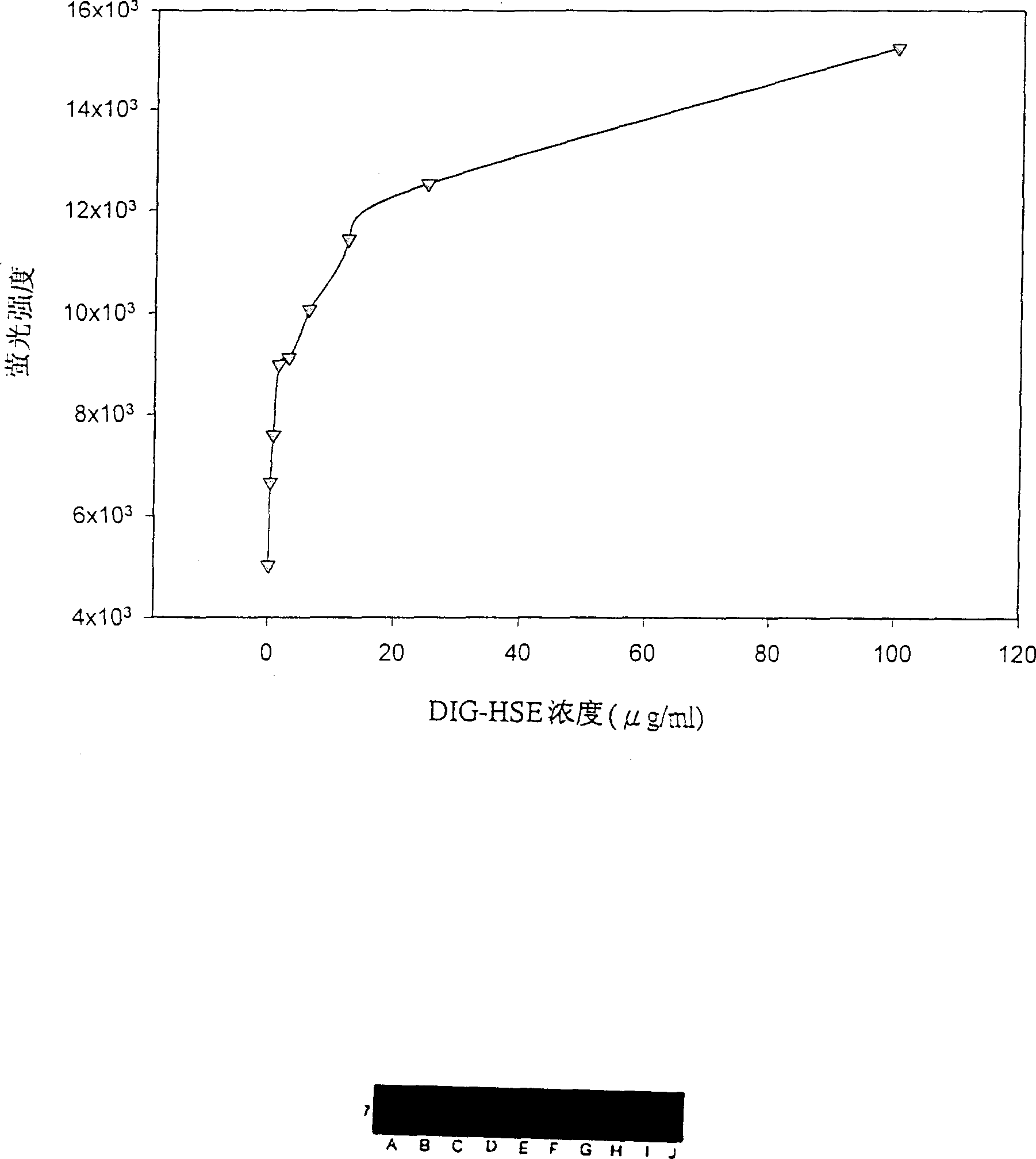

[0041] Fabrication of biochips that immobilize proteins, pendulums, or small-molecule compounds

[0042] Proteins, peptides or small molecule compounds were prepared on the treated polystyrene slides prepared in Example 1 using an automated device MicroGrid II (purchased from BioRobotics) equipped with a 0.4MM solid needle. The protein was dissolved in water-soluble buffer, and the peptide and small molecule compound were dissolved in DMSO to generate a stock solution, and then the stock solution containing protein, peptide and small molecule compound was diluted to 30% DMSO /

[0043] 0.1M carbonate buffer, pH 9.5 (the details of which are described in the "Results" section below). The solid syringe is used to deliver solutions containing proteins, peptides or small molecule compounds and form spots, so before loading each sample, rinse the solid syringe with double distilled water for 2 seconds, and then rinse the solid with 70% ETOH The needles were allowed to dry for 2 s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com