Plate-type double-side symmetrical-discharging ozone generator discharging chamber

A technology of ozone generator and discharge chamber, which is applied in the field of plate-type double-sided symmetrical discharge ozone generator discharge chamber, can solve the problems of the overall structure of the ozone generator, the complex structure of the discharge chamber, and the decline in the efficiency of the discharge chamber, so as to avoid heat Aggregation, simple structure, and the effect of increasing power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

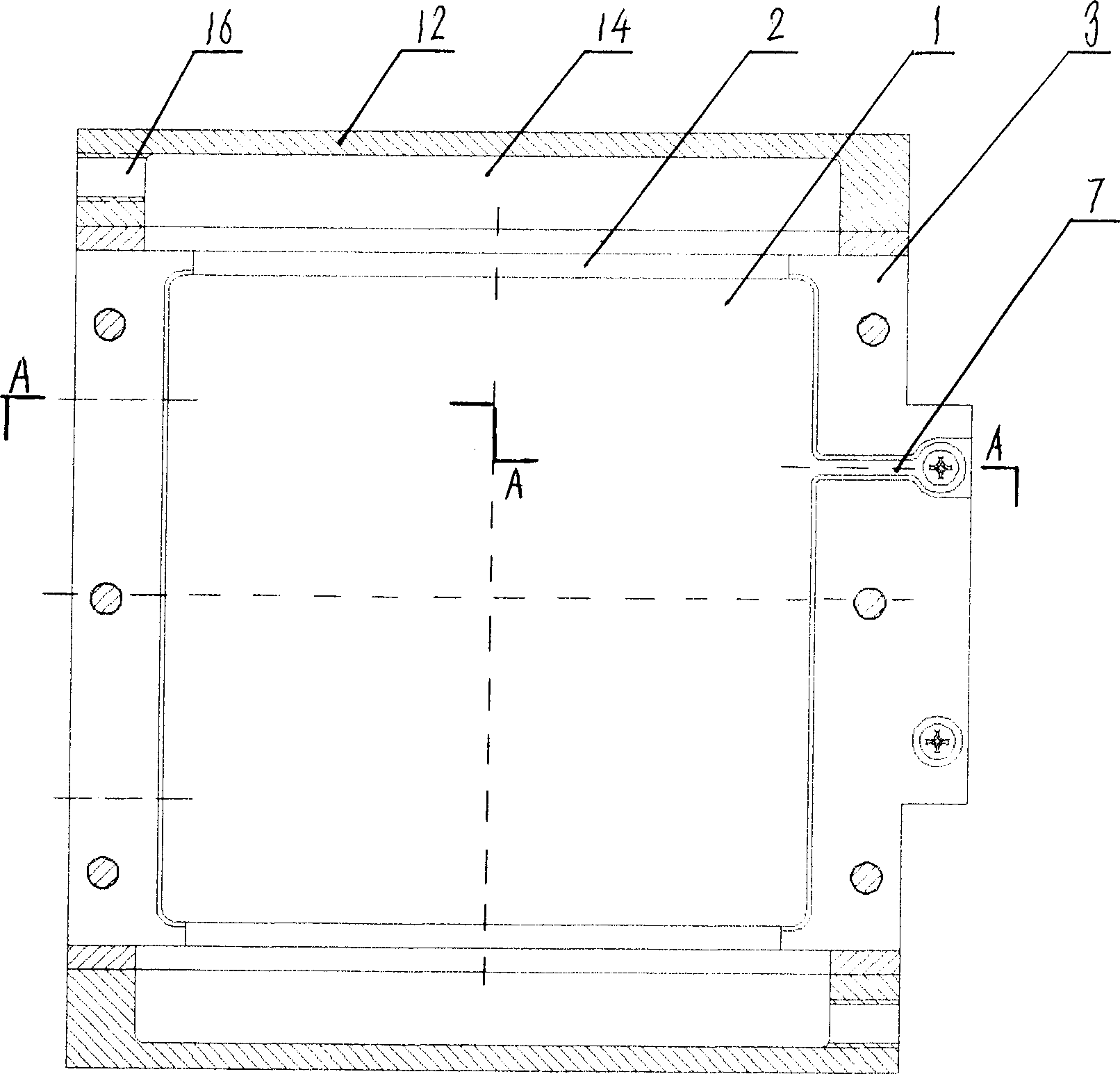

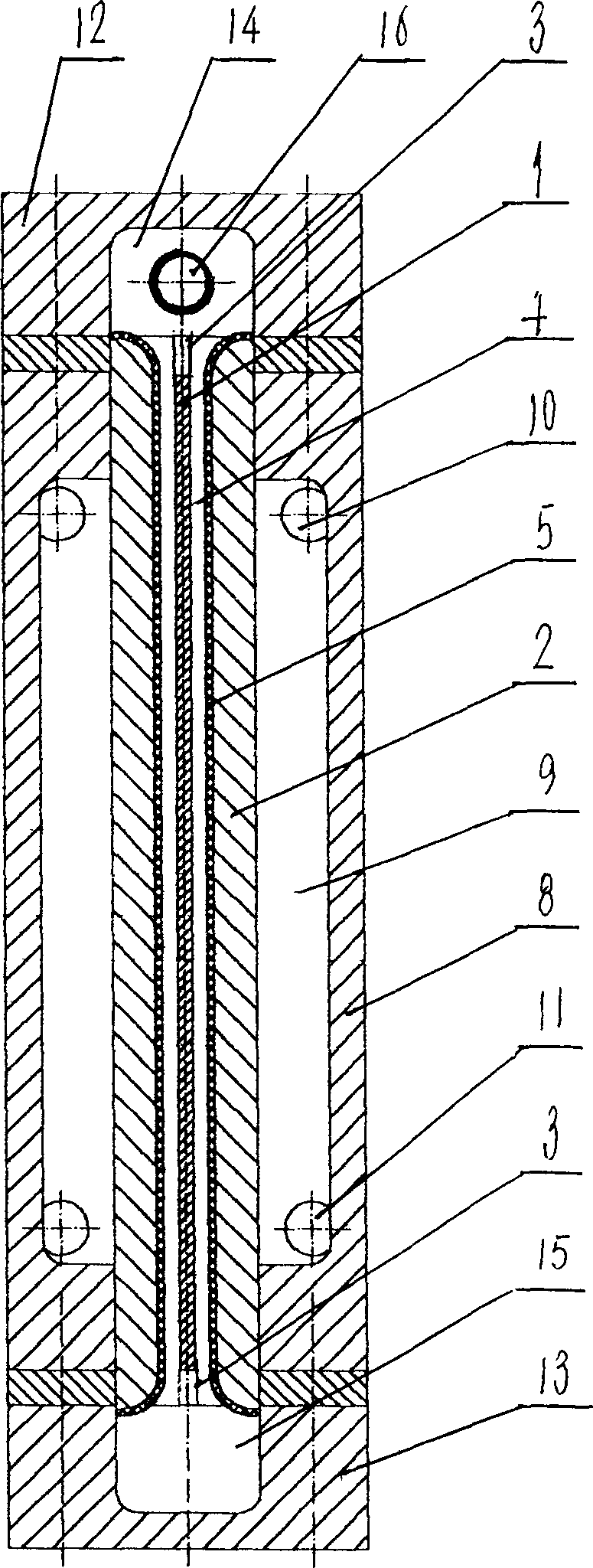

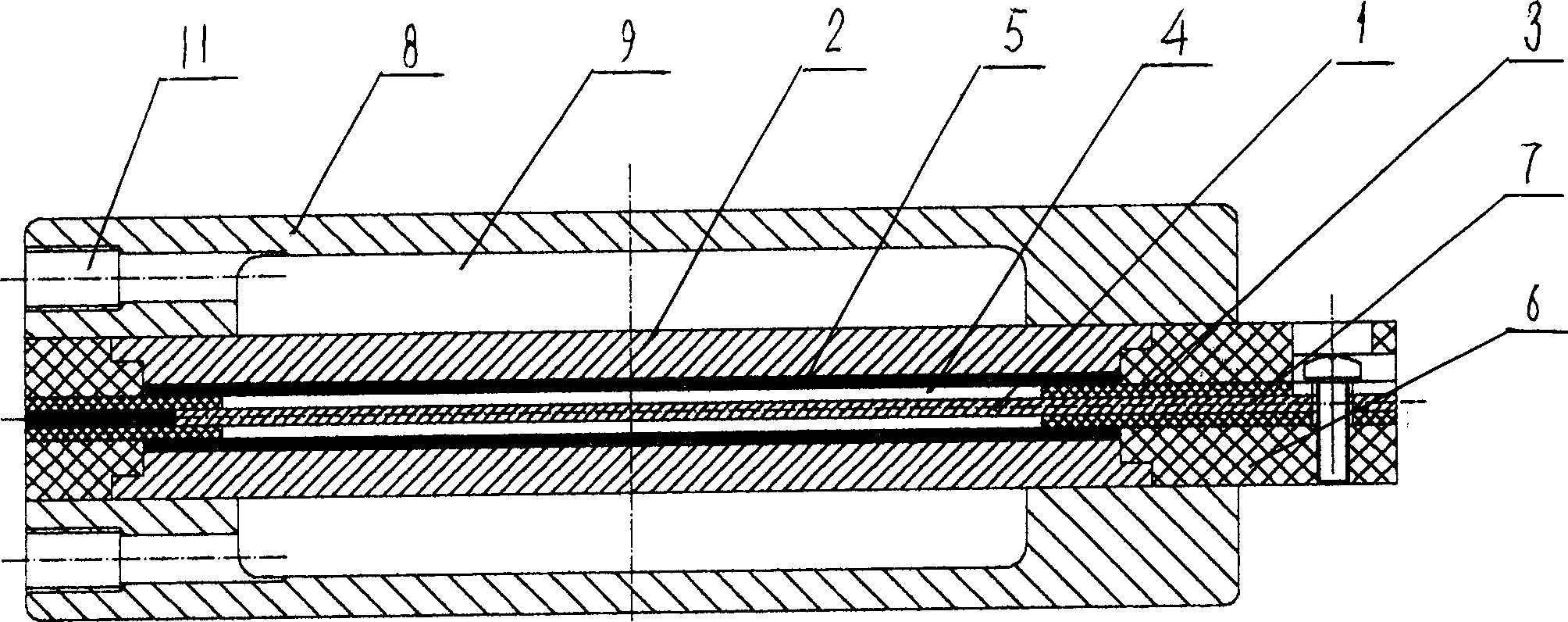

[0011] Such as Figure 1-3 The discharge chamber of the present invention's plate-solid double-sided symmetrical discharge ozone generator is mainly composed of a high-voltage pole plate, a ground pole plate, an outer shell, and an upper and a lower end cover. The high-voltage pole plate 1 is a rectangular flat plate made of stainless steel and its thickness is less than 0.5mm. The ground plate 2 includes two rectangular metal plates, which are symmetrically installed and fixed on the front and rear sides of the high-voltage pole plate 1 through the left and right insulating plates 3 and maintain a certain discharge gap 4 with the high-voltage pole plate 1. The size of the discharge gap 4 can be 0.3-0.8mm and is controlled by the thickness of the insulating plate 3. The inner surface of the ground plate 2 has a dielectric layer 5 of a certain thickness, such as an enamel dielectric layer directly sintered on a low-carbon steel ground plate or a ceramic dielectric layer attach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com