Scanning-tunnel microscope needle-tip automatic controlled etching instrument

A scanning tunnel and microscope technology, applied in the field of testing, can solve the problems of low success rate of needle tip, insufficient observation, and insufficient response, and achieve the effect of compact structure, saving manpower, and easy disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

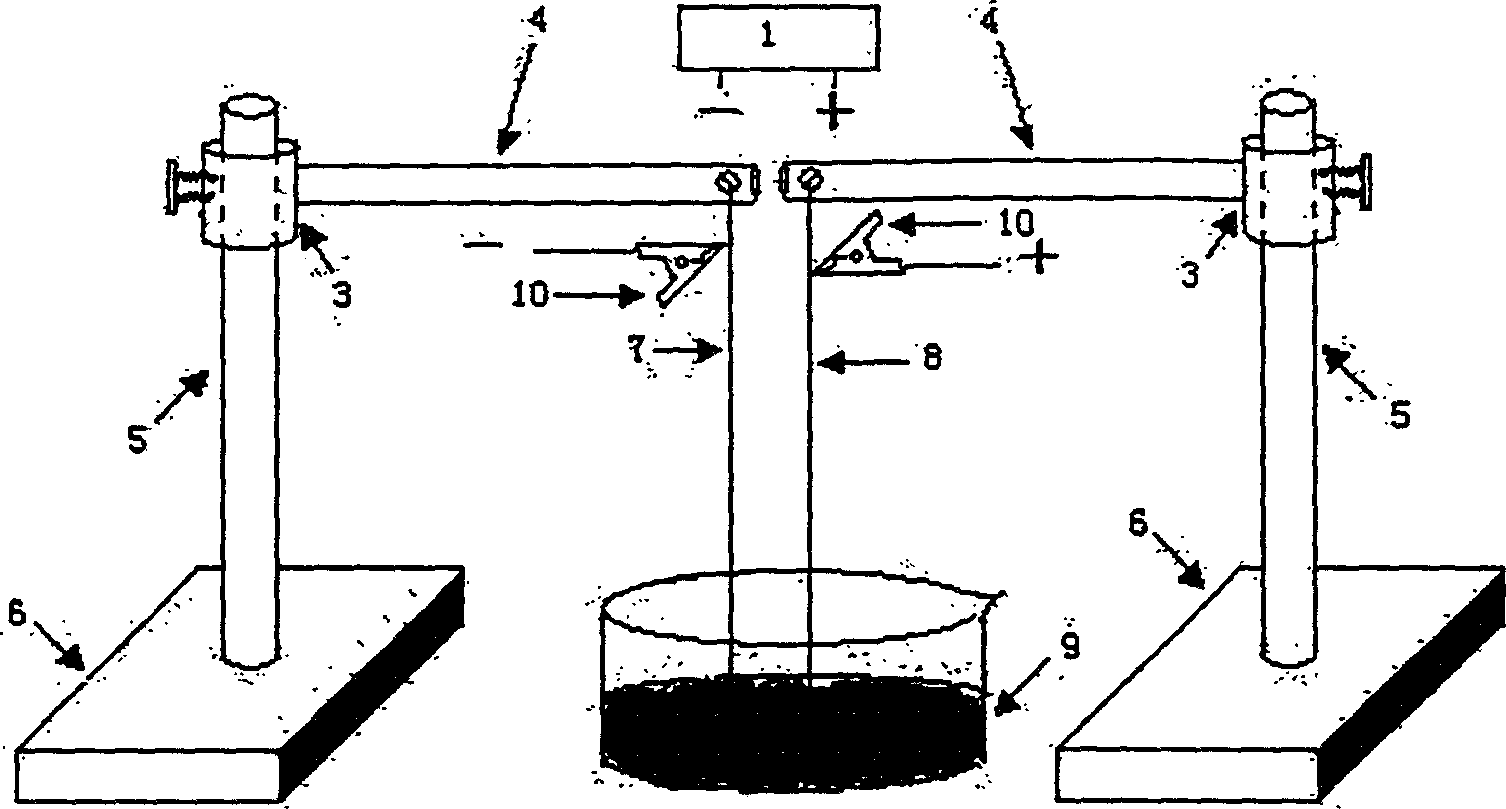

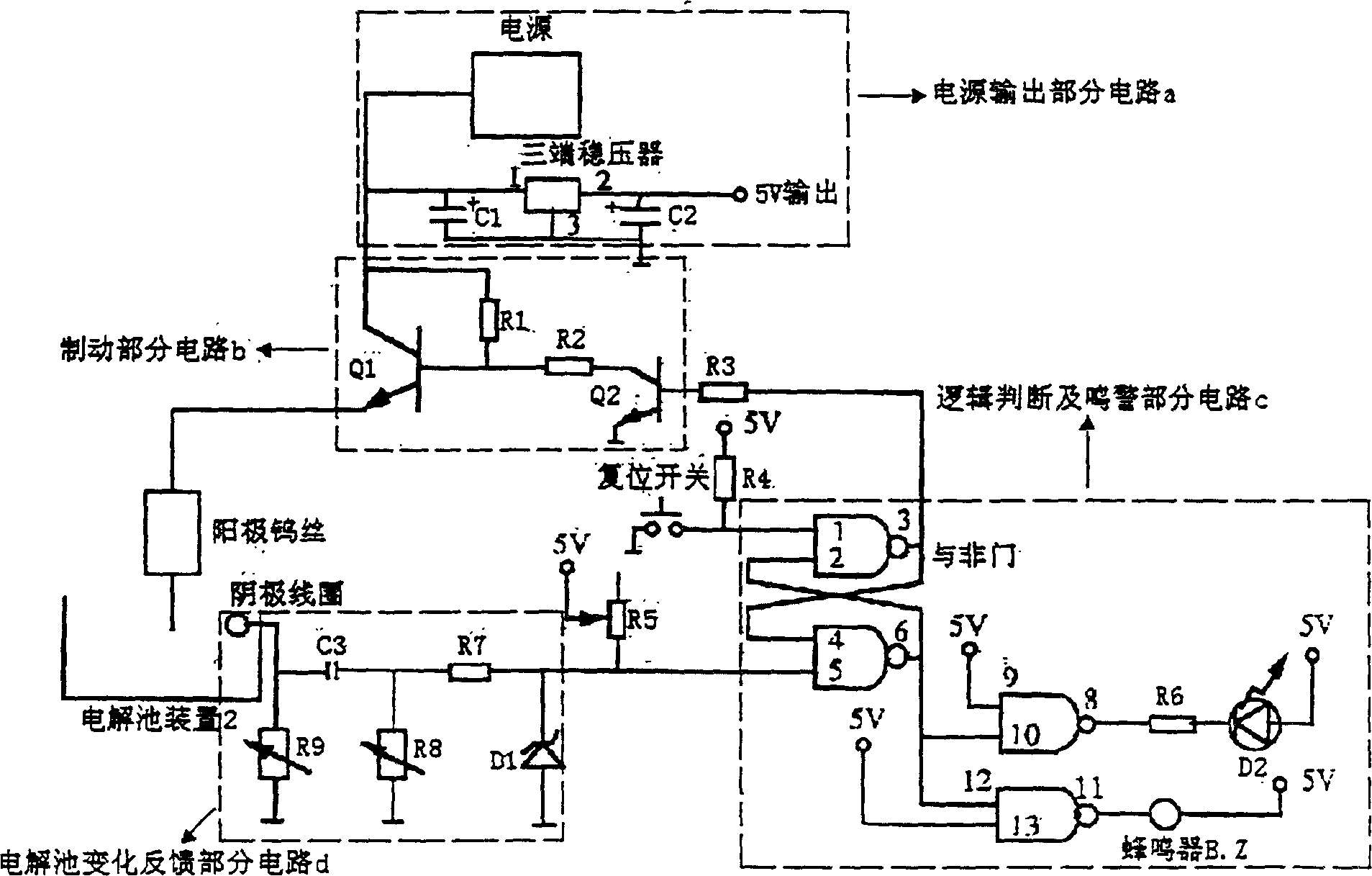

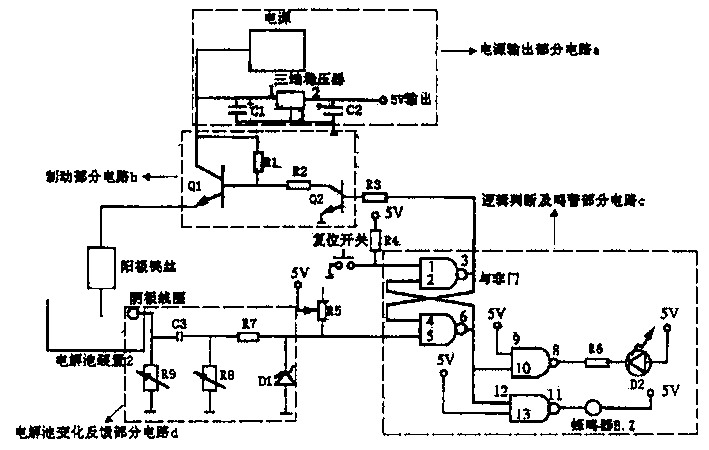

[0019] Such as figure 1 As shown, the present invention is composed of circuit 1 and electrolytic cell device 2. Circuit 1 includes power output part circuit a, braking part circuit b, logic judgment and alarm part circuit c, and electrolytic cell change feedback part circuit d. The electrolytic cell device 2 is composed of identical left and right parts, wherein one side of the two-way pipe 3 is welded with a cantilever 4, and the other side is respectively fixed on a central shaft 5 by a nut, and the two central shafts 5 are arranged on two bases 6, The ends of the two cantilevers 4 are respectively fixed with cathode coils 7 or anode tungsten wires 8 through nuts, and the electrolytic cell 9 filled with corrosive lye is set between the two bases 6 and clamped by crocodile clips 10 connected to the positive and negative poles of the circuit 1 respectively. The anode tungsten wire 8 and the upper part of the cathode coil 7 are used as the negative and positive electrodes of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com