Nano composite ceramic powder and its prepn process and application in energy economizer

A composite powder and nano-ceramic technology, used in other household appliances, applications, household appliances, etc., can solve the problem of easily damaged engines and exhaust pipes, the effect of exhaust emissions does not meet the national environmental protection standards, and the fuel-saving effect of energy-saving devices is not enough. Ideal and other problems to achieve the effect of increasing energy and burning rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Take powder Al 2 o 3 13kg, SiC 10kg, SiO 2 35 kg, TiO 2 25 kg, Er 2 o 3 12 kg, MgO 30 kg, and the above raw materials are mixed, stirred at high speed (6000r / m), dehydrated at low temperature (0°C-3°C), dried (80°C-150°C), and treated at room temperature in sequence to obtain nano-powder . First take kaolin (Al 2 o 3 : 2SiO 2 :H 2 (0) 60 kilograms, still crushed for the second time, dried, cooled, crushed and sieved to obtain activated kaolin. Then take 10 kilograms of nanometer powder, 35 kilograms of MgO, 65 kilograms of SiC, TiO 2 55 kg, Er 2 o 3 75 kg; then mix the above raw materials, and high-speed stirring (6000r / m), dehydration drying (80°C-150°C), drying treatment (300°C-500°C), calcining (800°C-1500°C), jet milling Machine pulverization to obtain nano-ceramic composite powder.

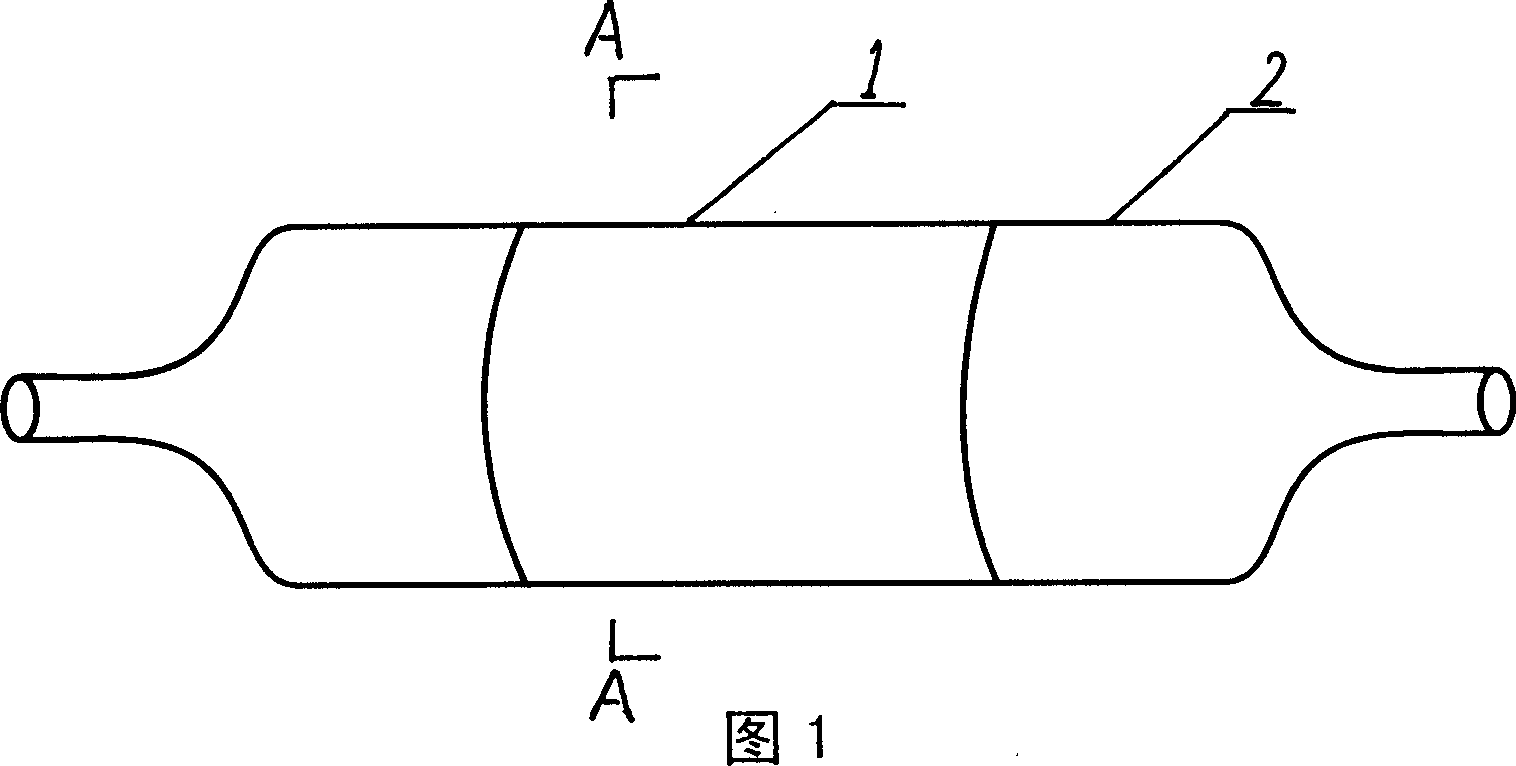

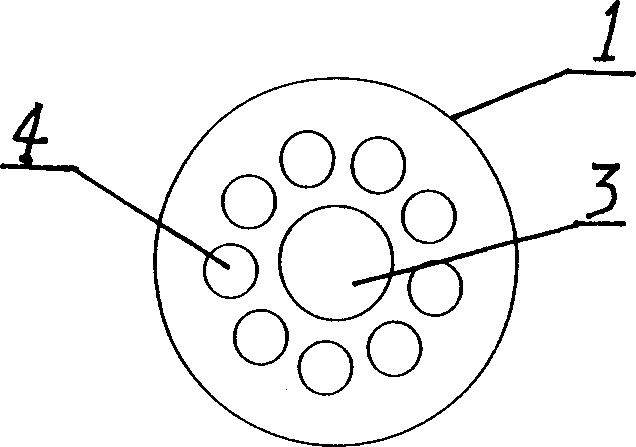

[0018] The nano-ceramic composite powder of the invention is used for the energy-saving device on the automobile. Nano-ceramic composite powder is used to form a b...

Embodiment 2

[0021] Take powder Al 2 o 3 8 kg, SiC 8 kg, SiO 2 29 kg, TiO 2 35 kg, Er 2 o 3 60 kg, MgO 40 kg, and the above raw materials are mixed, high-speed stirring (6000r / m), followed by low-temperature dehydration (0°C-3°C), drying (80°C-150°C), and normal temperature treatment to obtain nano-powder . First take kaolin (Al 2 o 3 : 2SiO 2 :H 2 O) 60 kilograms, successively crushed, dried, cooled, crushed and sieved to obtain activated kaolin. Then get 12 kilograms of nanometer powder, 40 kilograms of MgO, 75 kilograms of SiC, TiO 2 35 kg, Er 2 o 3 75 kg; then mix the above raw materials, and high-speed stirring (6000r / m), dehydration drying (80°C-150°C), drying treatment (300°C-500°C), calcining (800°C-1500°C), jet milling Machine pulverization to obtain nano-ceramic composite powder.

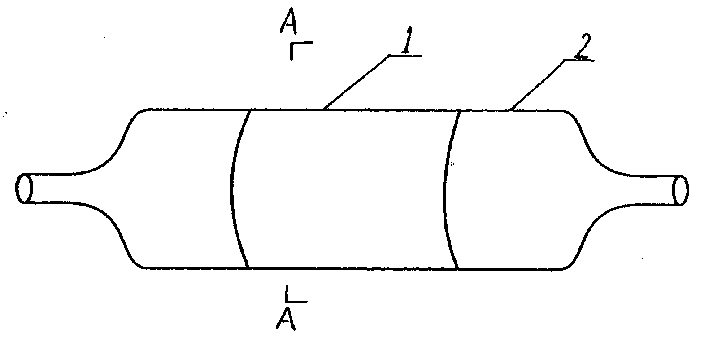

[0022] The nano economizer used in the gas cooker of the present invention adopts nano ceramic composite powder material to form a green tire to make an economizer with the same str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com