Over-unity production of clean new energies by recycling contaminated liquid waste

A recycling, liquid technology for waste fuels, hydrogen/syngas production, products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0105] Below we present preferred embodiments of the invention in all possible structural details, which serve to realize industrially all the features described above.

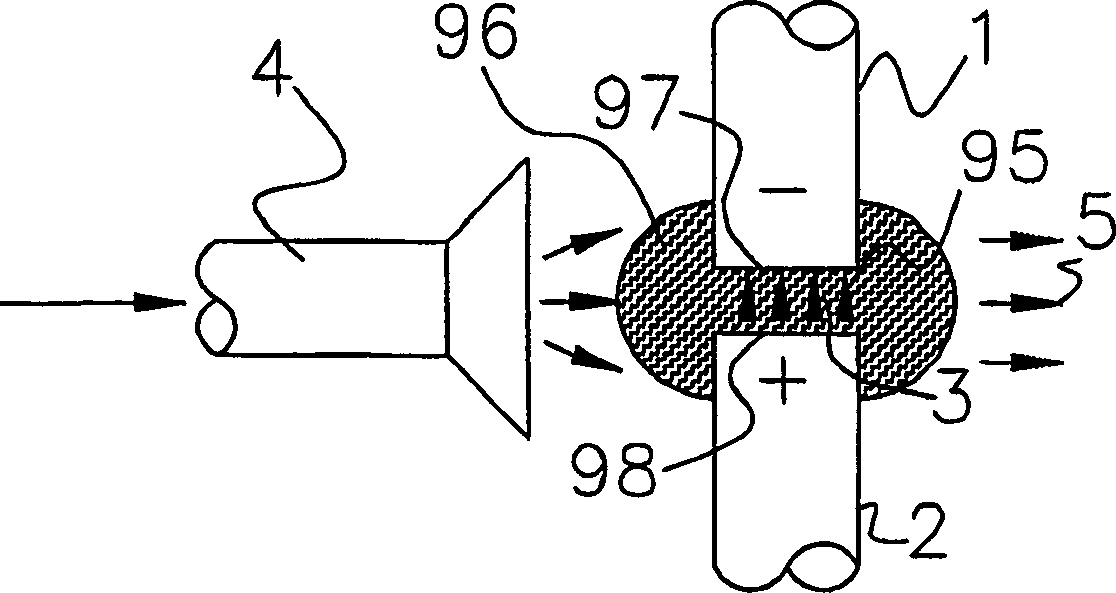

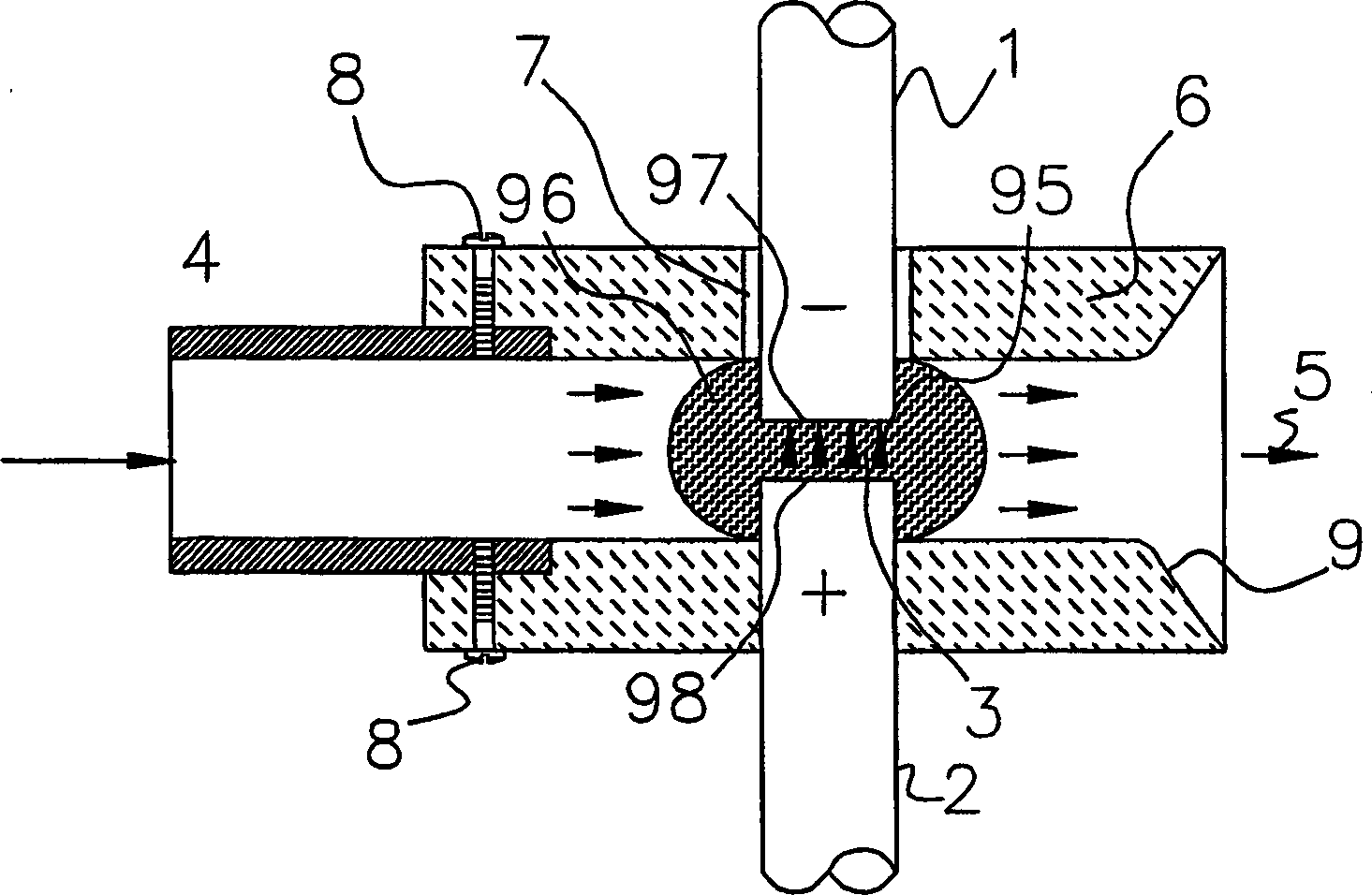

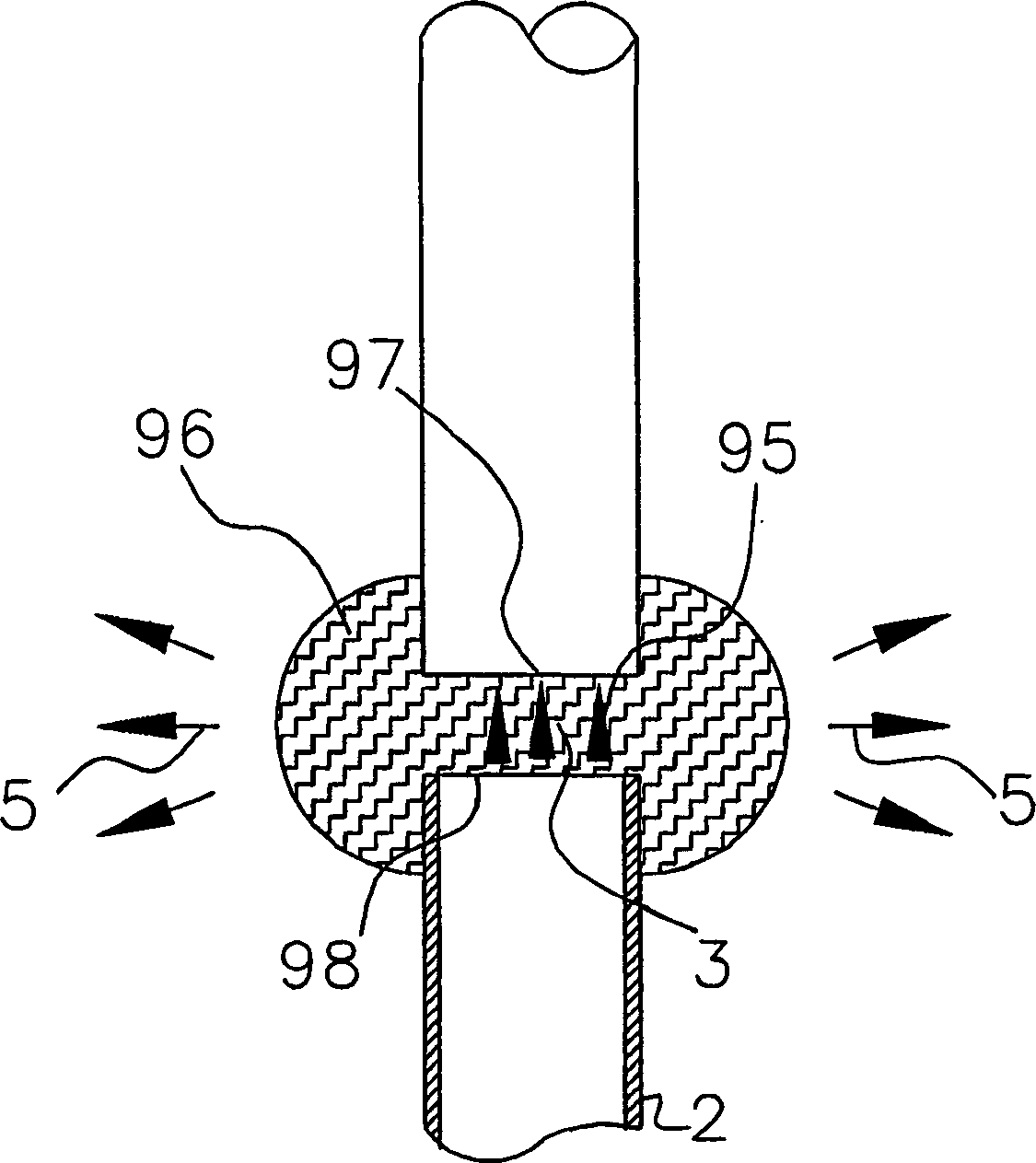

[0106] Now see the figure, Figure 1A The main principle of plasma arc flow is shown in co-pending U.S. Patent Application Serial No. 09 / 372278, which consists of two electrodes 1, 2 approximately 3 / 4 inch in diameter immersed in liquid waste to be recycled in Figure 2A The latter example shows this liquid waste, which is contained inside a metal container, in Figure 2A This container is also shown in the following examples. Make DC electric arc 95 appear between the top 97 of anode 1 and the top 98 of negative electrode 2, electron moves toward the top 97 with negative charge by positively charged top 98, with a 50Kwh DC power supply (in order to simplify Figure 1A Not shown in ) to power the arc 95, the distance between the tops 97, 98 of the electrodes 1, 2 is shown as the gap 3, generally speaking, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com