High molecular composite water-proof coil resisting prick of plant root and producing method

A waterproofing membrane and polymer technology, applied in layered products, chemical instruments and methods, building structures, etc., can solve problems such as poor resistance to plant root puncture, prevent nutrient soil loss, reduce engineering costs, The effect of protecting the waterproof root blocking material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

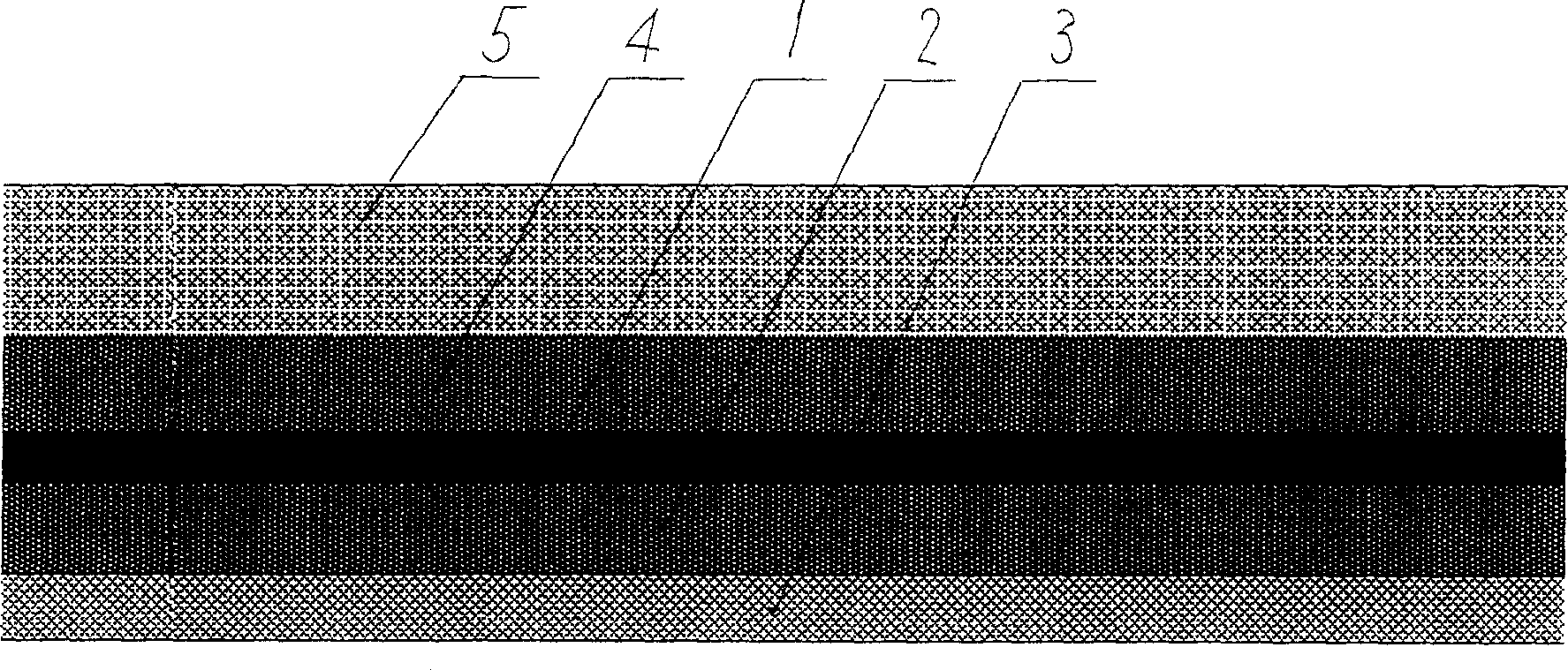

[0021] Example as figure 1 Shown: Both sides of the middle metal foil layer 1 are composited with maleic anhydride grafted modified polyethylene resin layer, the lower layer maleic anhydride grafted modified polyethylene resin layer 2 is bonded with non-woven fabric 3, and the upper layer maleic anhydride grafted modified polyethylene resin layer is bonded to it. A nonwoven fabric layer 5 is stuck on the branch modified polyethylene resin layer 4 .

Embodiment 2

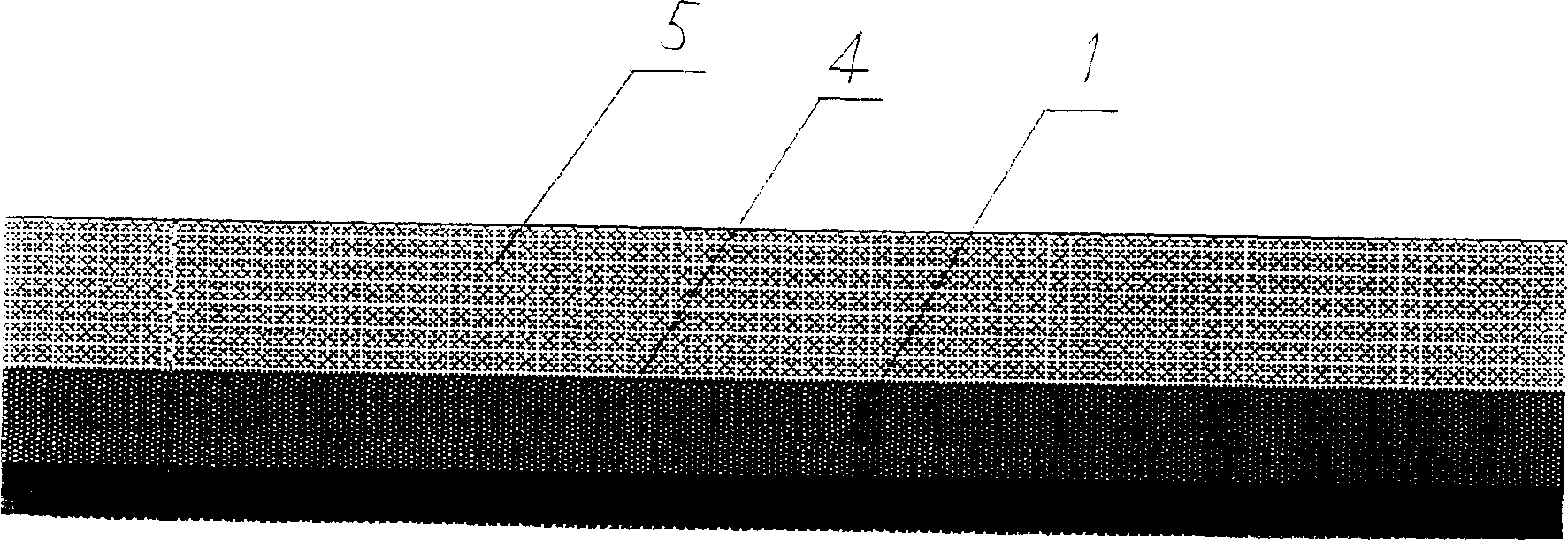

[0022] Embodiment two is a simple product such as figure 2 Shown: one side of the metal foil layer is compounded with a maleic anhydride grafted modified polyethylene resin layer, and a nonwoven fabric layer is adhered to the maleic anhydride grafted modified polyethylene resin layer.

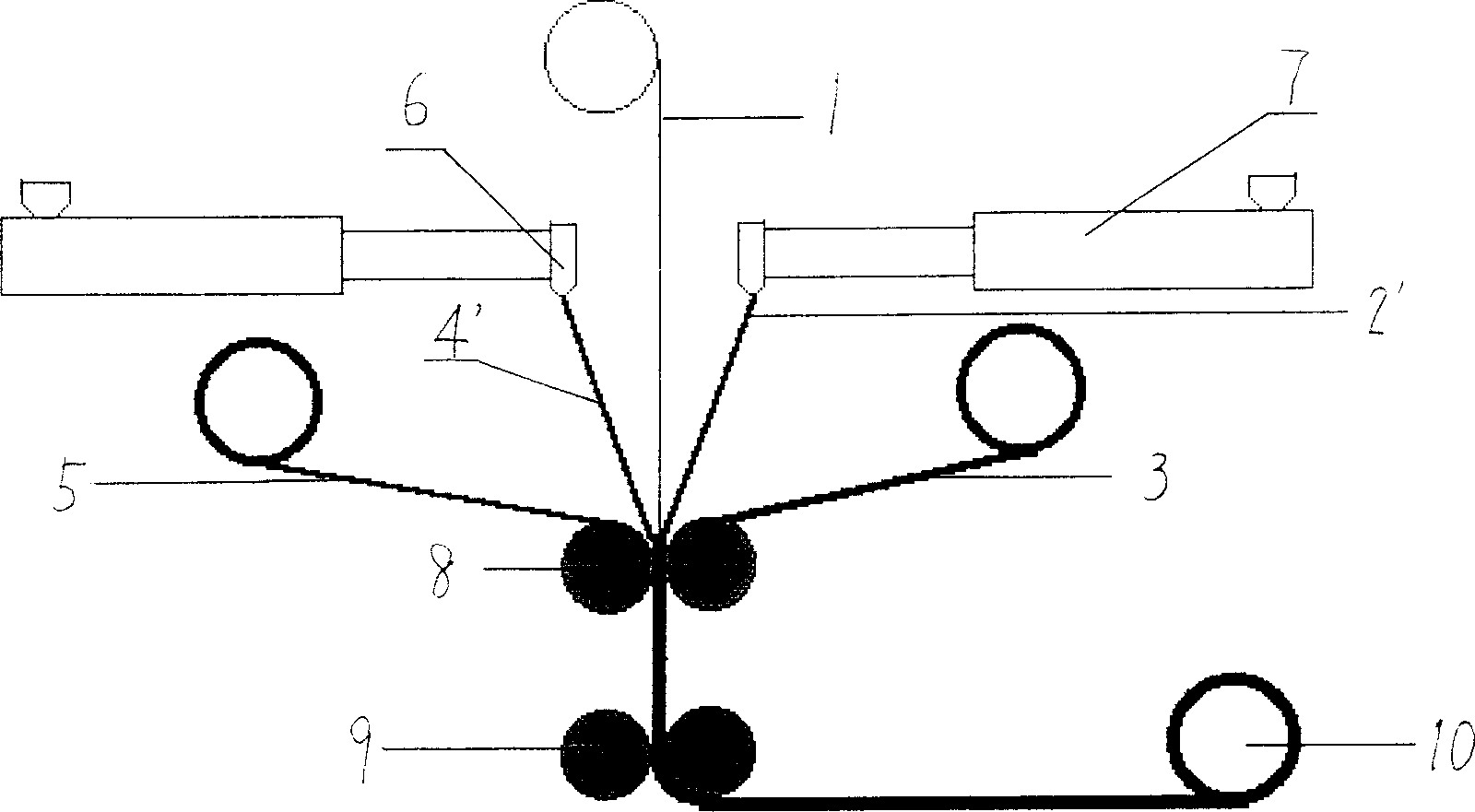

[0023] The first production method of the anti-plant root puncture polymer composite waterproof coiled material of the present invention: adopts the dual-die cast composite process flow and the extrusion cast plastic composite machine, and adds maleic anhydride grafted modified polyethylene resin into two Taiwan extruder die head 6,7, heat extrusion maleic anhydride graft modified polyethylene resin casting film layer 2 ', 4 ', metal foil layer 1 is placed between two extruder die heads, put Two rolls of non-woven fabrics 3 and 5 are placed outside the die heads of the two extruders. The above five layers of materials are unrolled and flattened, and then pressed into one body by the heat-seali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com