Rapid energy transfer tempering device and method

A technology of energy transmission and tempering device, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., and can solve problems such as unstable energy density, high surface roughness and poor uniformity of polysilicon thin film layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described below in conjunction with the accompanying drawings, and those skilled in the art should understand that the following description is only for illustration purposes, and is not intended to limit the present invention.

[0032] 【The first preferred embodiment】

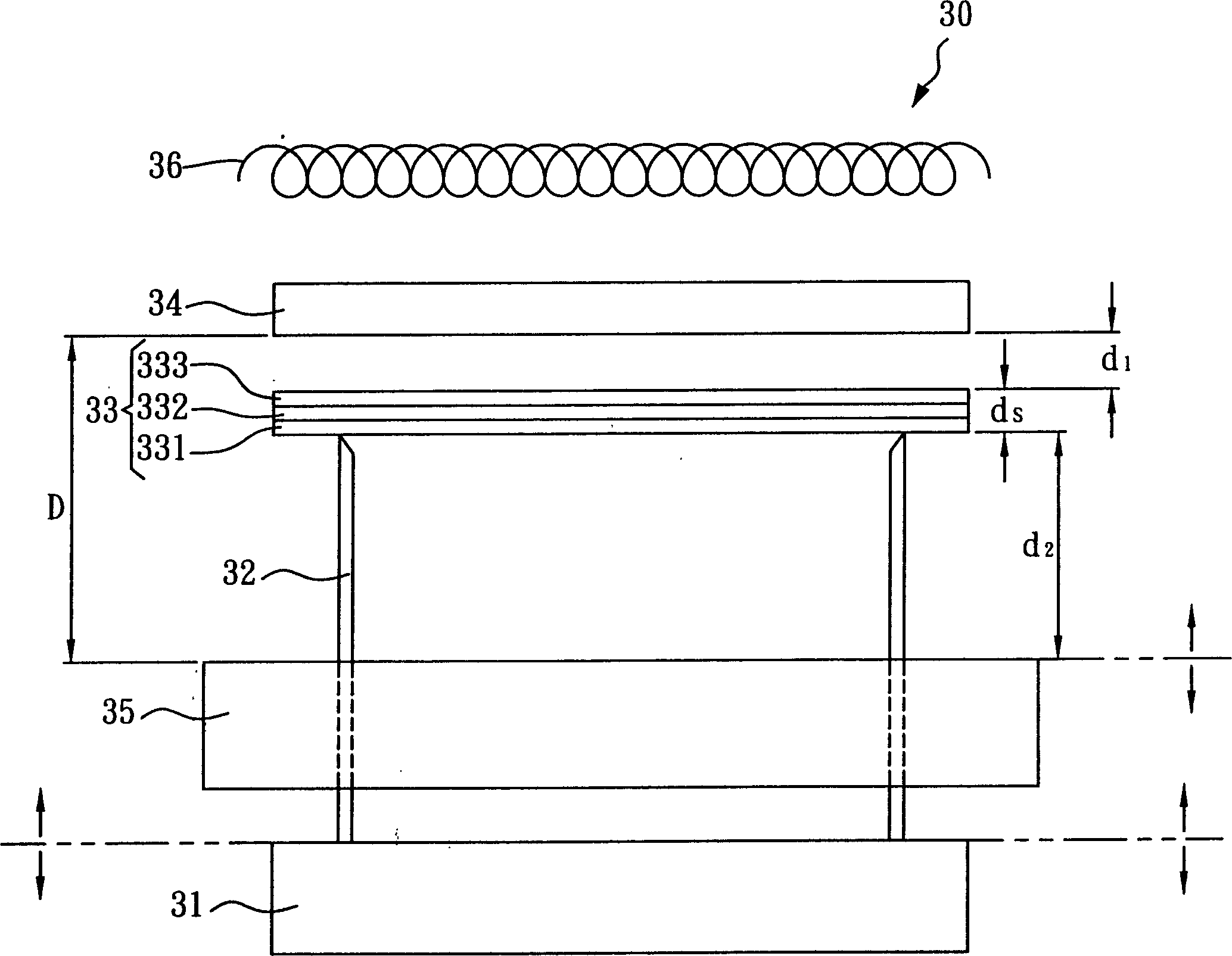

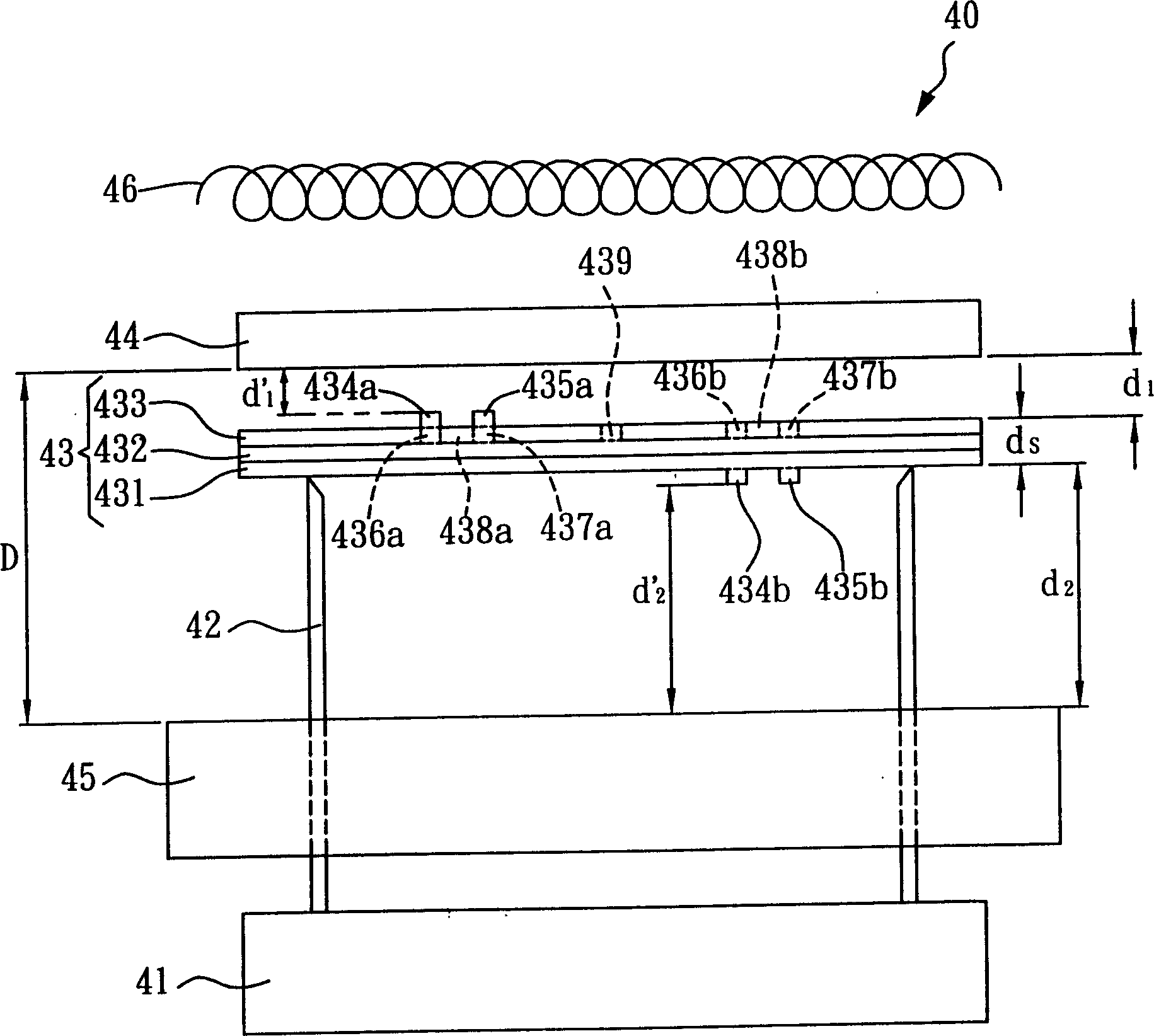

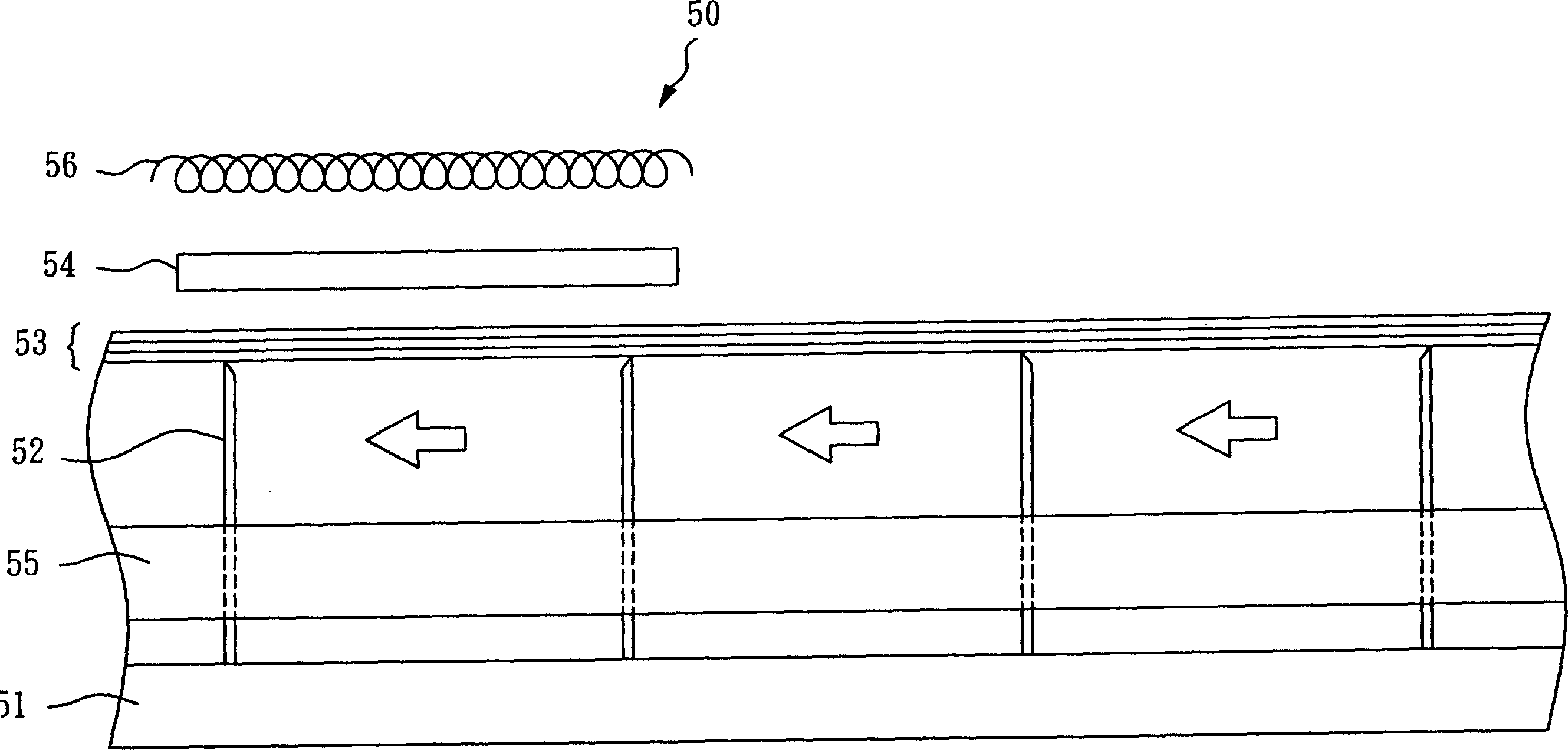

[0033] figure 1 It is a schematic diagram of the rapid energy transmission tempering device 30 of the first preferred embodiment of the present invention, including: a plurality of quartz columns 32 fixed on a carrier plate 31, a test piece 33 supported by a plurality of quartz columns 32 and having a thickness of dS , the test piece comprises a glass substrate 331, a silicon dioxide layer 332 and an amorphous silicon thin film layer 333 deposited sequentially on the glass substrate 331; an energy plate 34 is located at a first distance d1 above the test piece 33; A heat dissipation plate 35 is located at a second distance d2 below the test piece 33, allowing a plurality o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com