Information record mdeium, information recored method and information replay method

A technology for information recording and media, applied in recording/reproducing/deleting methods, optical recording/reproducing/erasing methods, temperature recording methods, etc., can solve the problem of swinging, very large, and uncontrollable balls at the beginning and end of recording marks size distribution etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (structure, manufacturing method)

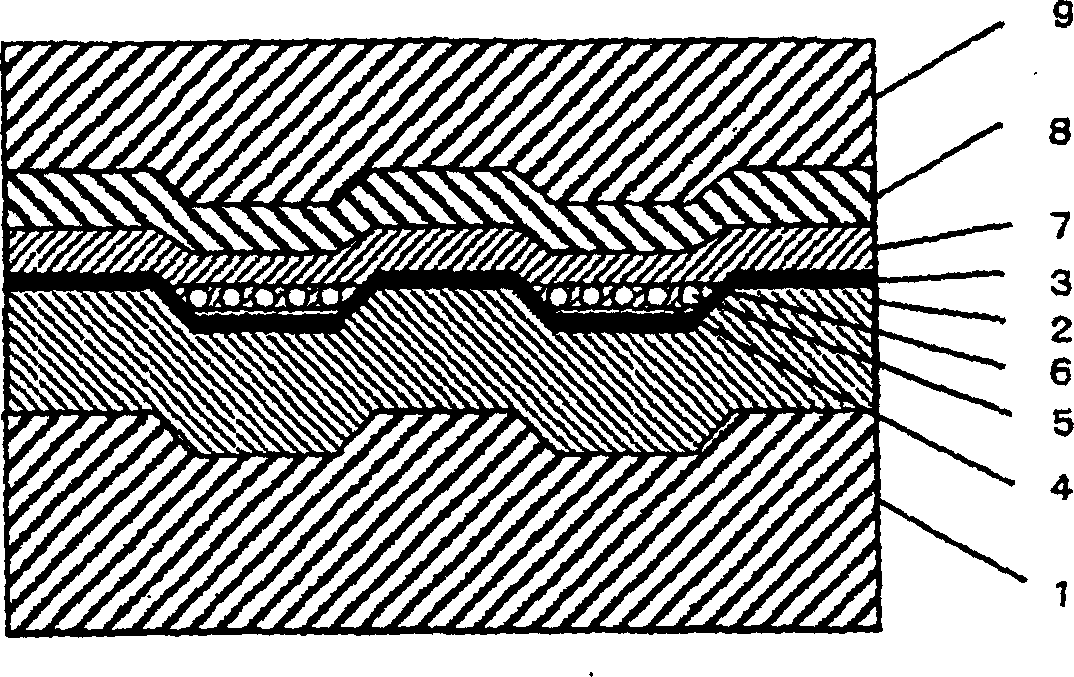

[0027] The recording medium of the present invention has figure 1 structure shown.

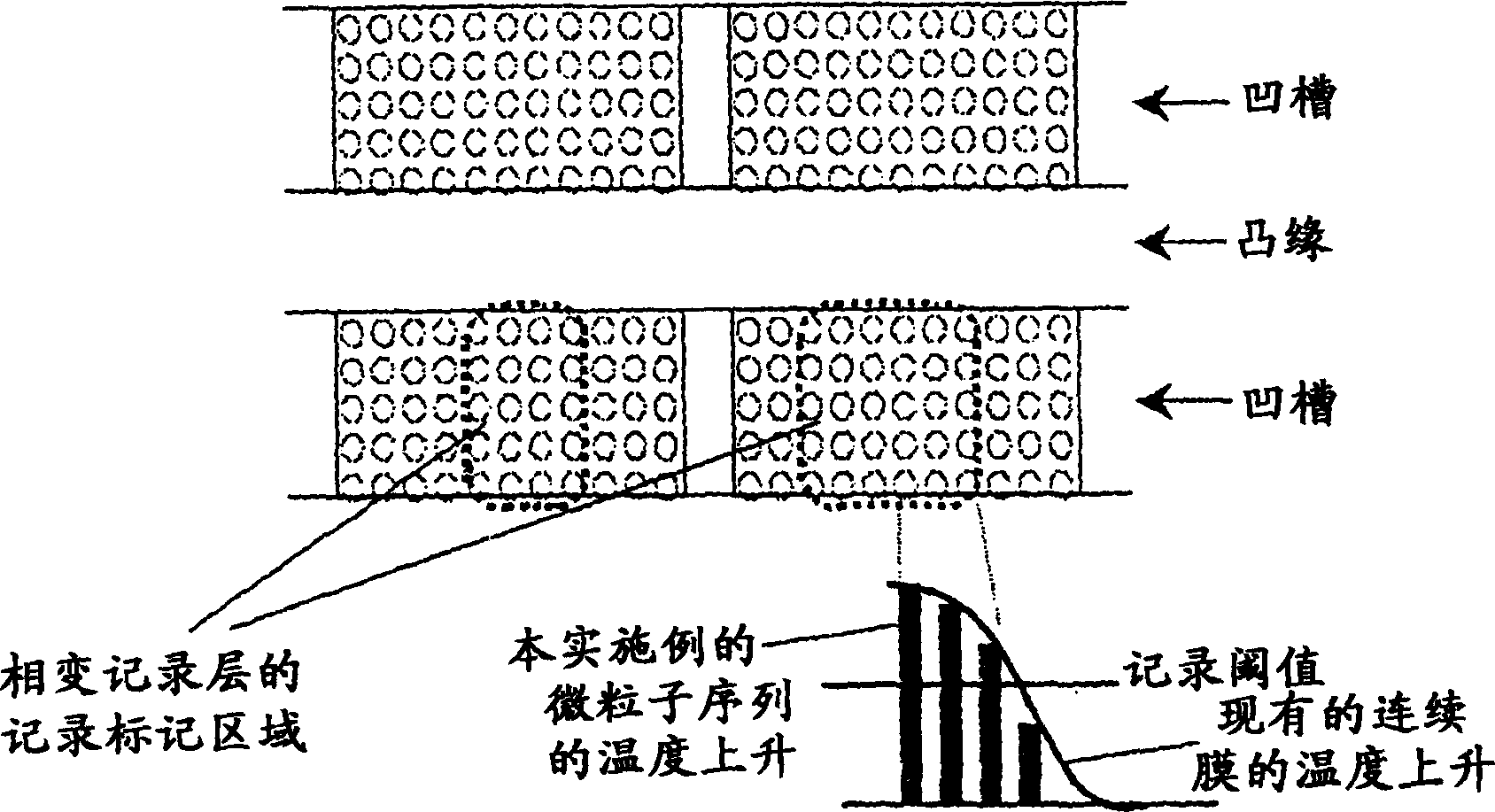

[0028] This medium was produced as described below. First, on a surface with a diameter of 8 cm and a thickness of 0.6 mm, there is a tracking groove (width 0.15 microns) for recording in a groove with a track pitch of 0.4 microns and a depth of 25 nm (here, land recording viewed from the light spot). , on the polycarbonate substrate 1 that expresses the address through the swing of the groove, the film thickness of 50nm is formed by (ZnS) 80 (Sio 2 ) 20 The lower protective layer 2 is formed. A phase-change recording film 3 made of Ge2Sb2Te5 having a film thickness of 10 nm was formed thereon. The groove pattern is transferred to the surface of the substrate by using a nickel master plate coated with a photoresist film on the original plate. As described in J.Am.Chem.Soc.vol.124, No.12, p2884 (2002) of the paper J.Am.Chem.Soc.vol.124, No.12, p...

Embodiment 2

[0071] The recording medium and device structure are the same as in Embodiment 1, but multi-valued recording is used as the recording method. Multi-valued recording is performed by changing the ratio of recording marks to the unit length on the recording track. In the case of performing multi-valued recording on a common phase-change recording medium, as in Figure 8 on page 20 (2001) of the Proceedings of the paper PCDOS2001 by M.Horie et al. Figure 4 As shown, distortion in the shape of recording marks cannot be avoided, and errors in readout signals are likely to occur. However, in the self-bonded recording medium utilizing the present invention, even if the same recording is performed, the shape of the mark is correct, such as Figure 5 A reproduced signal having a quaternary level can be accurately obtained as shown in the example of the waveform trace of the reproduced signal after processing. When the levels shown by the four horizontal lines in the figure are divided...

Embodiment 3

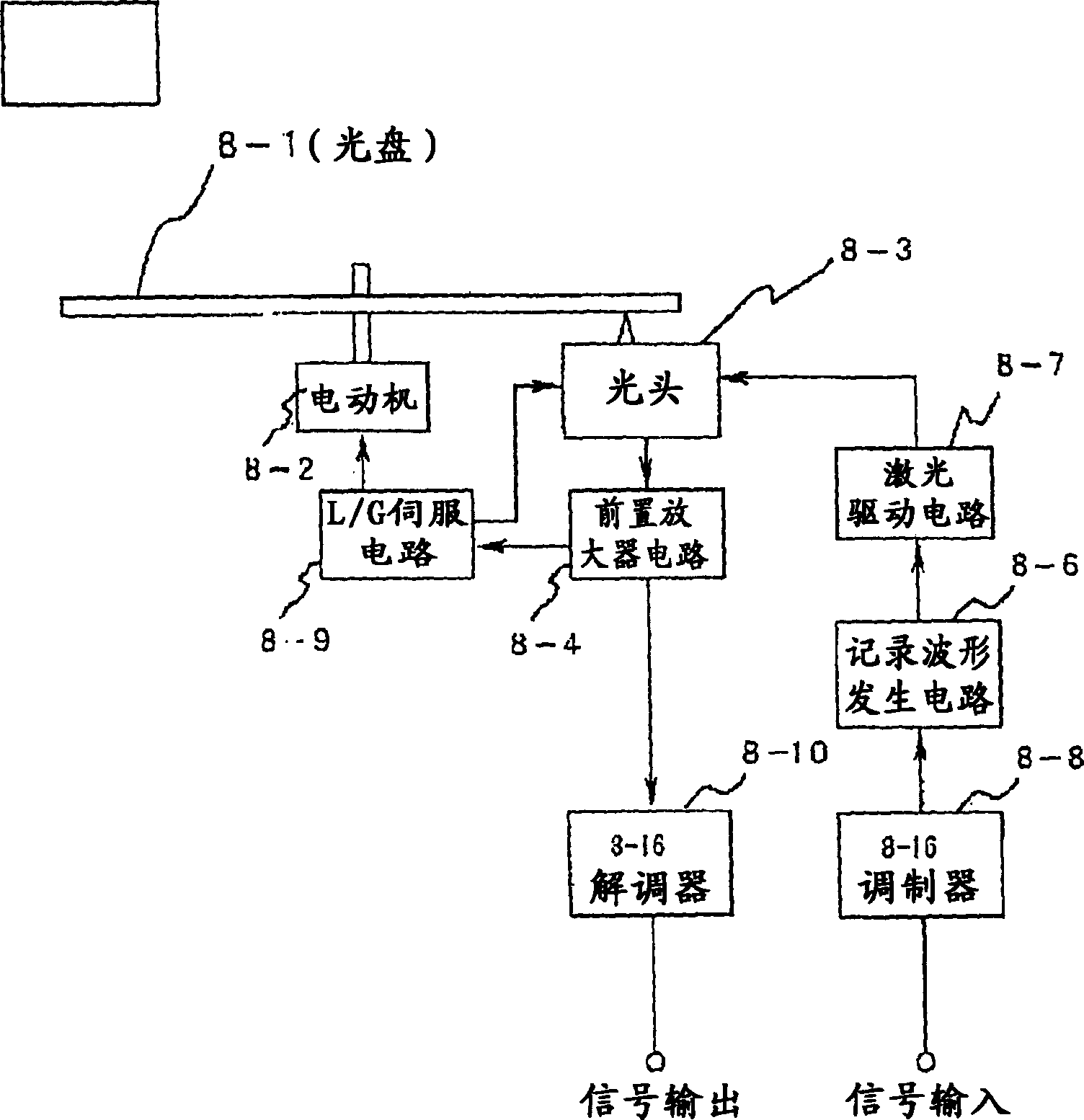

[0073] This embodiment relates to a multilayer structure recording medium and a recording apparatus using it.

[0074] Such as Figure 6 As shown, the first layer of the recording medium was formed in the same manner as in Example 1. However, since the wavelength of the light source used in the experiment is relatively long, a wide format with a track pitch of 1 µm and a groove width of 0.3 µm was used. Microparticles are not metal, but in SiO 2 After setting a cyanine pigment layer with a thickness of 5 nm around it, oleic acid was attached around it. No Ge-Sb-Te recording layer was provided. For automatic positioning and tracking, a 10nm-thick translucent Ag layer is first set on the surface of the substrate. 95 PD 3 Cu 2 Composed of translucent reflective layer 11. exist Figure 6 in, from figure 1 Shown between the recording layer and the upper protective layer are the layers 13 and 17 etc. which are not written in detail with broad bold oblique lines. SiO surrou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com