Wave length adjustable vertical cavity surface emitting laser diode

A surface-emitting laser, vertical cavity technology, used in lasers, laser parts, semiconductor lasers, etc., can solve the problems of high gain loss of laser resonance characteristics, difficulty in rapidly changing operating temperature, and increase in operating temperature, and achieve widened wavelength tunable. area, the effect of avoiding the deterioration of the laser resonance gain characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

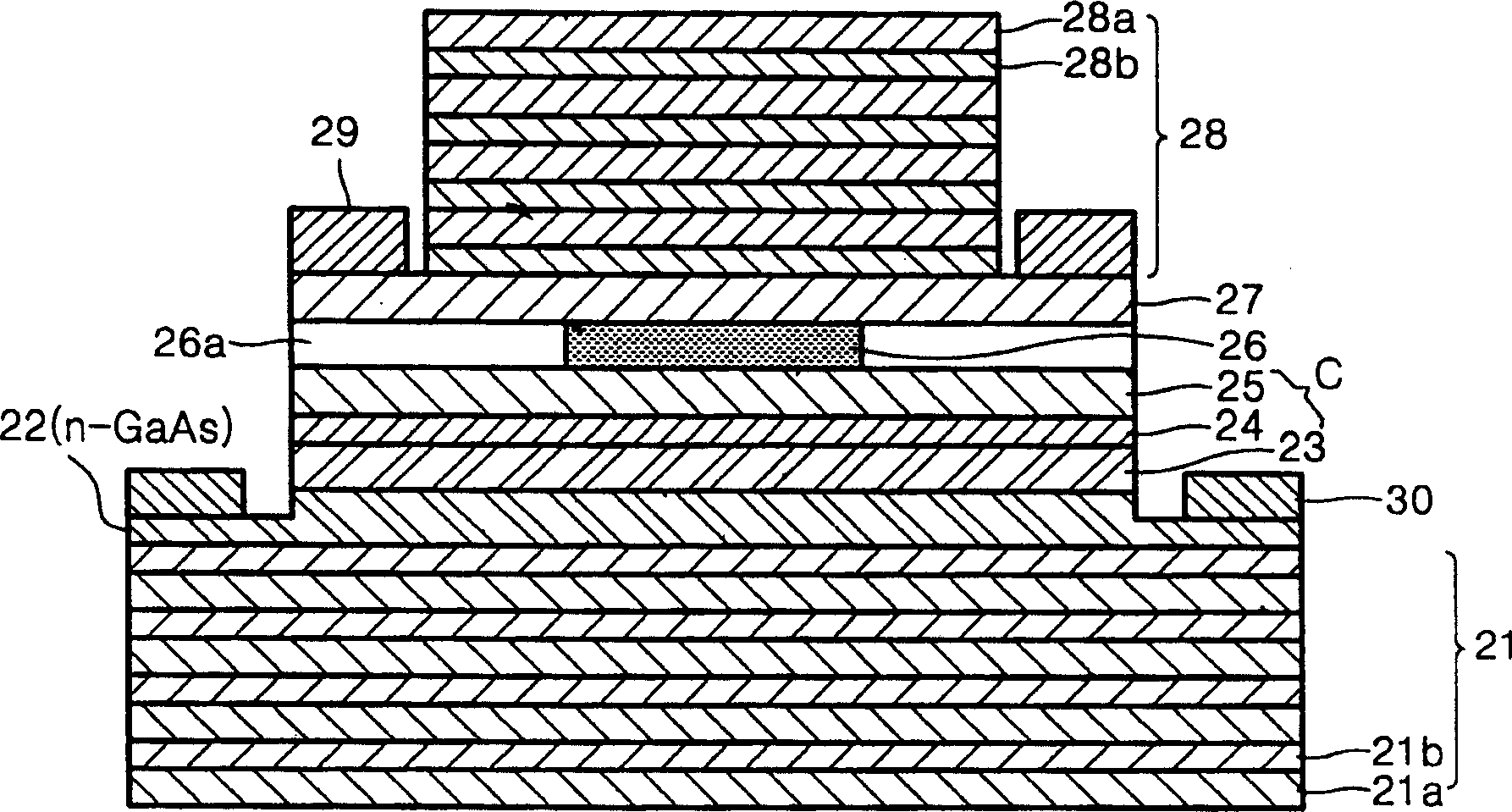

[0018] The wavelength tunable VCSEL in an embodiment of the present invention will be described below with reference to the accompanying drawings. In the drawings, the thickness of layers or regions are exaggerated for clarity.

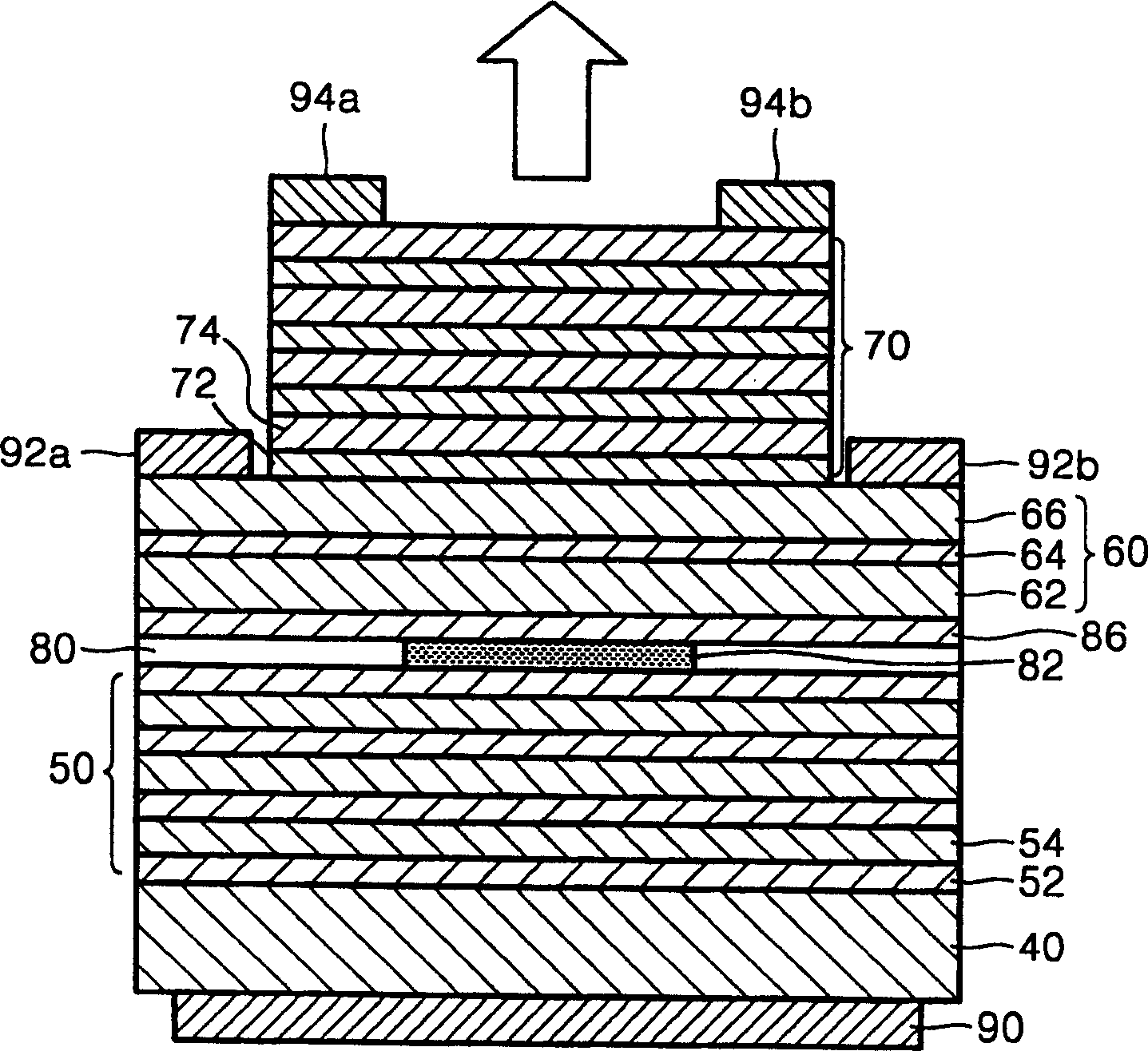

[0019] see figure 2 , reference numeral 40 denotes a substrate, which is a compound semiconductor substrate on which upper and lower distributed Bragg reflectors (DBRs) 50 and 70 and a cavity resonance layer 60 are formed. A lower DBR 50 is formed on the substrate 40 . The lower DBR 50 is formed by alternately stacking first and second compound semiconductor layers 52 and 54 . The first and second compound semiconductor layers 52 and 54 preferably do not absorb light emitted from the cavity resonance layer 60 . Therefore, the energy bandgap of the first and second compound semiconductor layers 52 and 54 is preferably larger than the resonance wavelength. For example, both the first and second compound semiconductor layers 52 and 54 are preferably...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com