Heliogreenhouse in bi-directional and shed sape

A technology for solar greenhouses and greenhouses, applied in the field of solar greenhouses, can solve the problems of low land utilization, high construction costs, and high construction costs, and achieve the effects of reducing investment and cultivated land, high returns, and reducing heating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

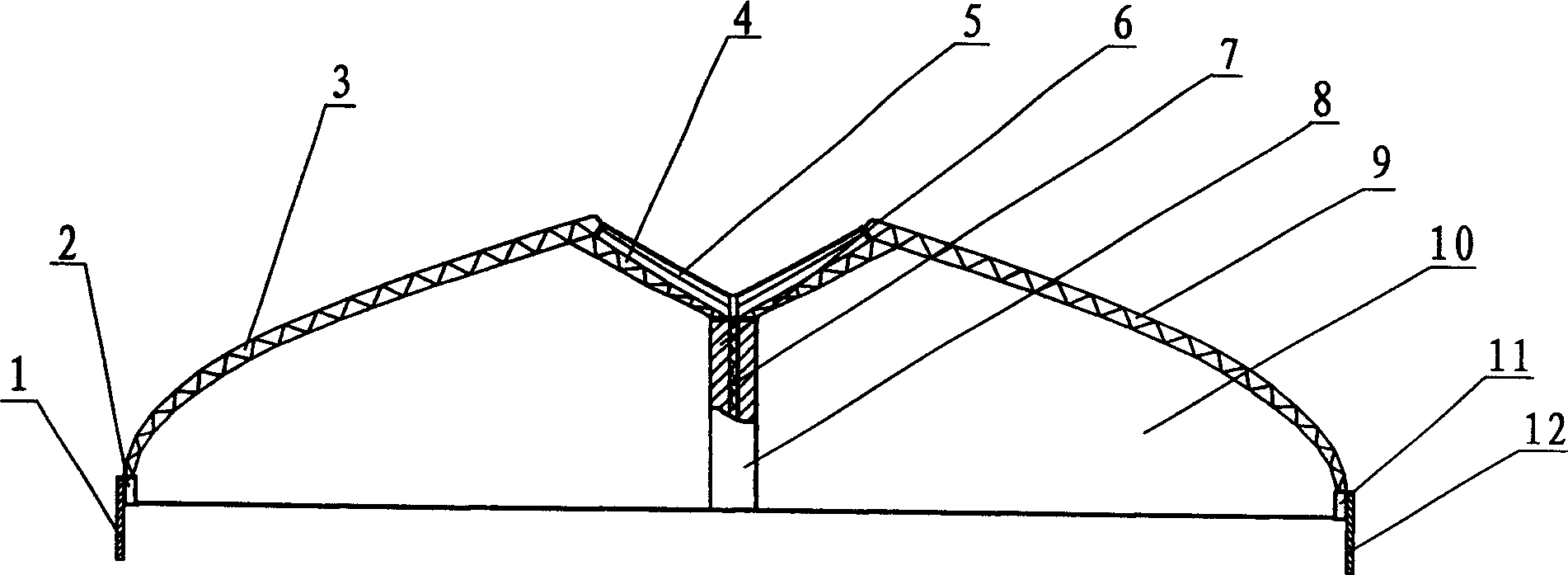

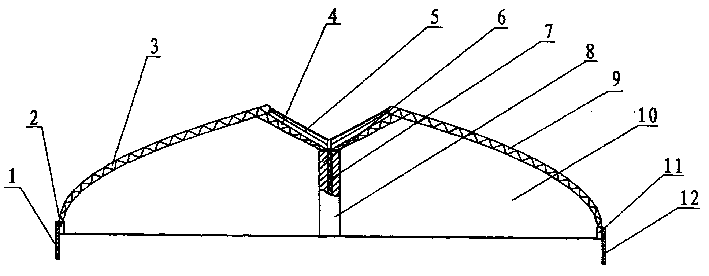

[0008] exist figure 1 Among them, the two-way single-slope solar greenhouse has an enclosure wall, which is composed of a rear wall 8 and gable walls 10 on both sides of the rear wall 8 . It also has skeletons 3, 9 and shed film. The back wall 8 is a composite thermal insulation wall, and a 120mm or 90mm thick benzene board insulation layer 7 is sandwiched in the middle of the rear wall 8, and both sides of the wall insulation layer 7 are 240mm thick brick wall layers 6, forming a composite Insulated walls. The back wall 8 is an intermediate wall shared by the two solar greenhouses in the north and the south. While the back wall 8 serves as a load-bearing wall, it also has better thermal insulation and heat storage performance. On the front and rear sides of the rear wall 8, there is a ridge wall 2, 11 respectively, and a cold-proof ditch is arranged outside the ridge wall 2, 11, and a benzene board insulation layer with a thickness of 50-80mm and a height of 800-1000mm is b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com