Compound vessel and adhesive for use, decomposition method for cpmpound vessel

A composite container and adhesive technology, applied in the direction of adhesives, adhesive additives, polymer adhesive additives, etc., can solve problems such as uneven decomposition surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

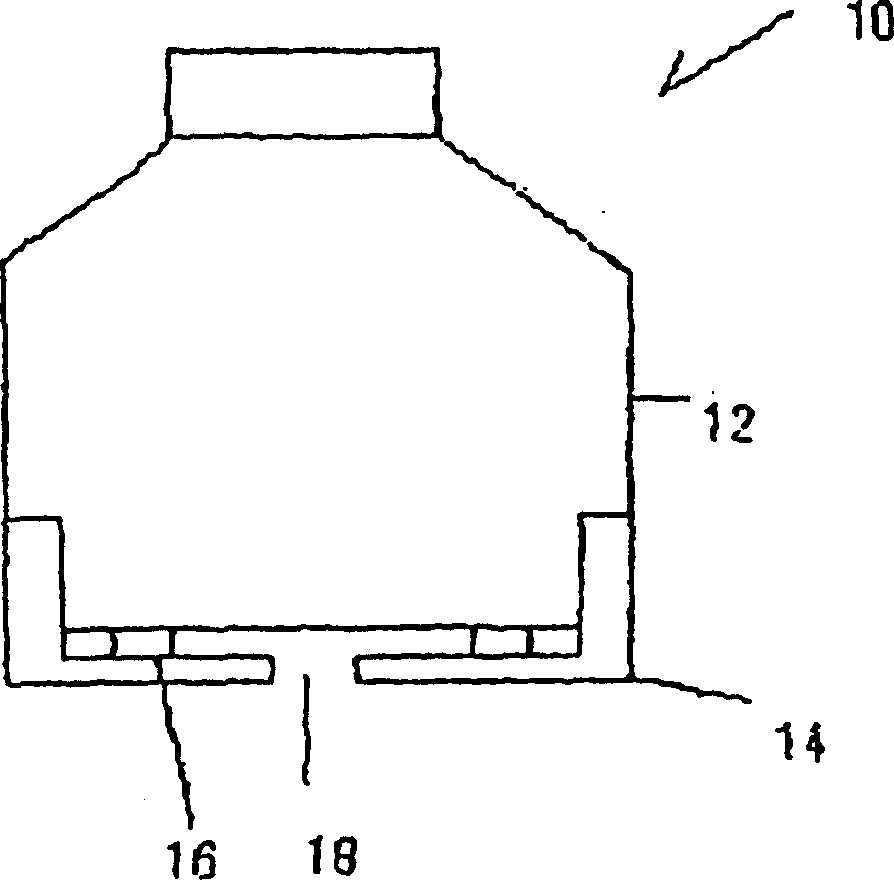

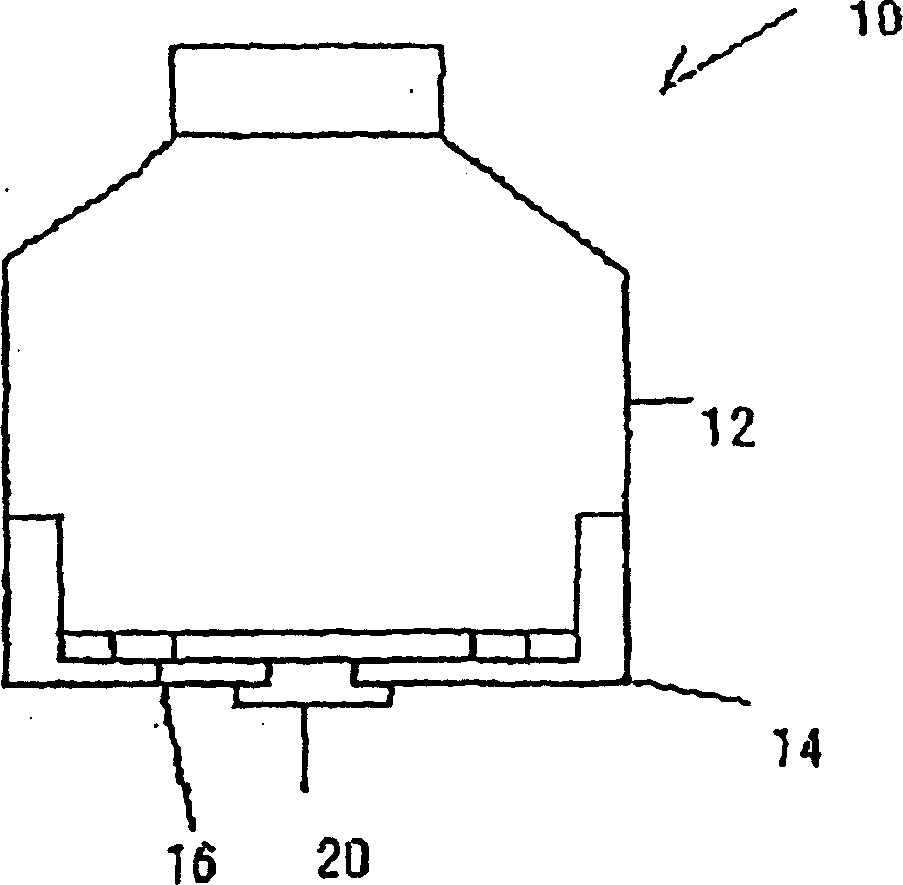

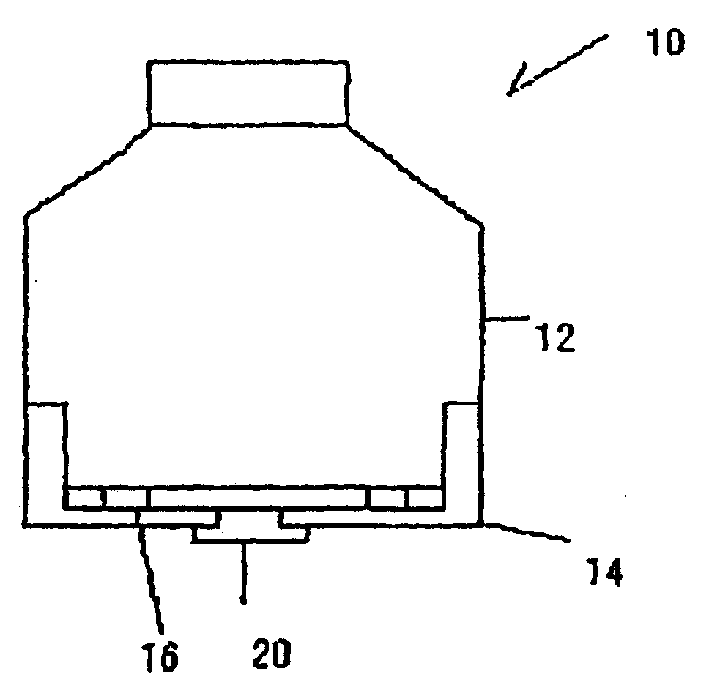

[0182] Below by example, this patent is described in more detail. The composite container of the example is composed of a glass container and a metal base. The scope of application of this patent will certainly not be limited to examples, and this point should not need further explanation.

example 1

[0184] (1) Manufacture of adhesive

[0185] The temperature of the melting bowl should be kept at 180°C. The matrix resin is SIS block polymer, and the anti-acidification agent is a phenolic anti-acidification agent. The ratio of matrix resin: anti-acidification agent = 100 weight units: 0.2 weight units , Put the two into a melting bowl, use a mixer, and melt while stirring. The stirring and melting time is 3 hours, so that the two are mixed evenly and melted evenly.

[0186] Next, add 3 30 weight units of C5 hydrogenated petroleum resin; water-absorbing macromolecular structure particles adopt isobutylene structure anhydrous maleic acid copolymer, (average particle diameter: 15um, water absorption rate: 200 times) added 35 weight units; interface activity What the agent adopts is polyglycol-glycerol stearate ether, (HLB: 15.7) adds 7 weight units; What the plasticizer adopts is liquid paraffin (fire point: 256 ℃, density: 0.865g / cm 3 ) into 5 weight units; continue to stir...

example 4

[0199] The binding agent of example 4, except surfactant, other ingredients are all identical with example 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| ignition point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com