Lithium secondary battery

A lithium secondary battery, potential technology, applied in the direction of secondary battery, lithium storage battery, secondary battery repair/maintenance, etc., can solve the problem of battery rupture, no overcharge safety, fire and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

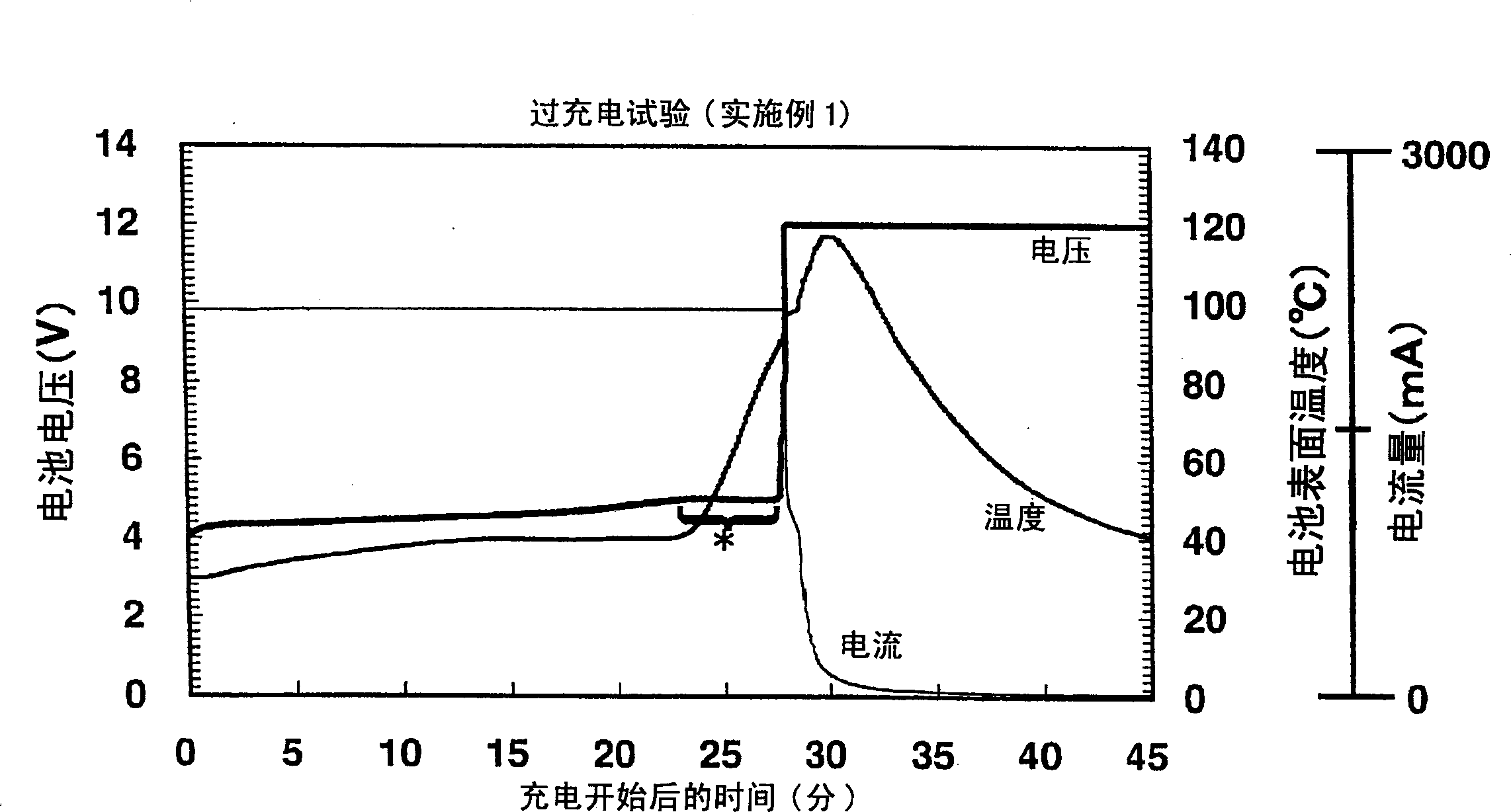

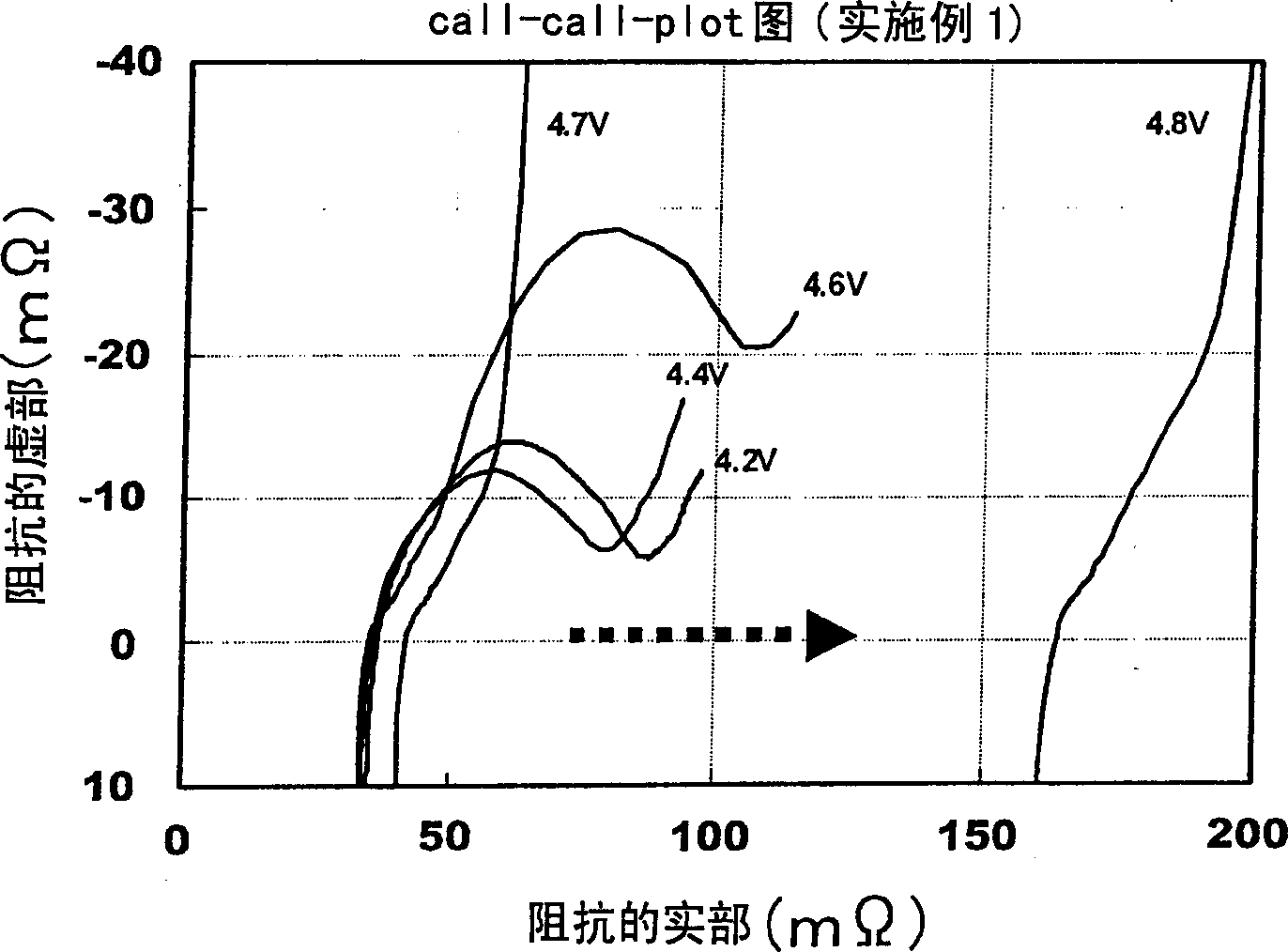

Embodiment 1

[0027] The lithium secondary battery of Example 1 was fabricated as described below.

[0028] Make positive electrode

[0029] The positive electrode active material lithium cobaltate and the carbon conductive agent graphite were mixed at a mass ratio of 92:54 to make positive electrode mixture powder, which was filled into a mixing device (Mekanofujiyon device (AM-15F) manufactured by Hosokawa Micron Co., Ltd.). The mixing device was operated at a rotational speed of 1500 rpm (rev / min) for 10 minutes to apply compression, impact and shear force to the above powder to prepare a mixed positive electrode active material. This mixed positive electrode active material and fluorine-containing resin binder (polyvinylidene chloride: PVDF) are mixed in N-methylpyrrolidone (NMP) solvent by the mass ratio of 97:3, make positive electrode mixture slurry, this The slurry is coated on both sides of the aluminum foil, dried and then rolled to make a positive plate.

[0030] Make negat...

Embodiment 2

[0037]Except using tetrahydrofuran (THF) instead of 1,2-dimethoxyethane (DME) in the electrolytic solution, the same operation as in Example 1 was performed to manufacture a battery.

Embodiment 3

[0039] A battery was fabricated in the same manner as in Example 1 except that 2-methyltetrahydrofuran (2-MeTHF) was used instead of 1,2-dimethoxyethane (DME) in the electrolyte.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com