Method for making glass product

A manufacturing method and technology of glass products, applied in glass manufacturing equipment, glass molding, glass pressing, etc., can solve problems such as sharp increase in defect rate and uneven surface layer state of glass raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

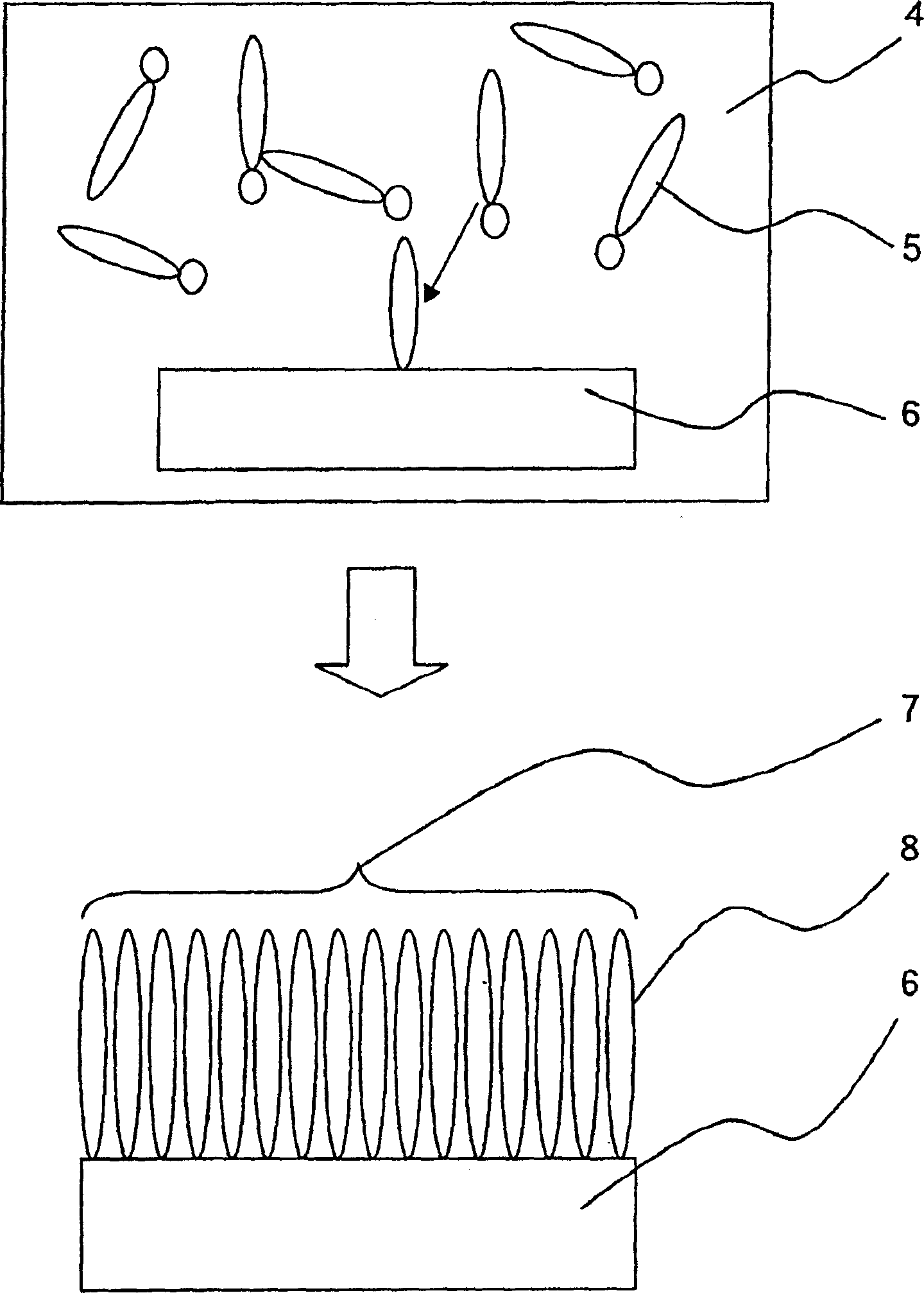

Method used

Image

Examples

Embodiment 1

[0139] For optical element molding raw materials that have been washed with high precision by the wet cleaning method with a commercially available precision cleaning machine for optics, and stored in a high-clean environment in nitrogen after washing, sampling inspections are performed for each washing and storage lot. With pure water and CH 2 I 2 The wetting angle was determined by the Owens-Wendt-Kaelble method to evaluate the surface free energy. Minimum surface free energy value of 68mJ / m for all batches 2 Above, the surface free energy that satisfies the claims of the present invention is at 60mJ / m 2 above.

[0140] In addition, high-precision washing by the wet washing method is performed as follows.

[0141] ①Tap water tank (ultrasonic) for 1 minute→②Tap water tank (ultrasonic) for 1 minute→③Washing tank (ultrasonic) for 1 minute→④Pure water tank (ultrasonic) for 1 minute→⑤Pure water tank (ultrasonic) for 1 minute→⑥Isopropanol tank (Ultrasonic) for 1 minute → ⑦ Is...

Embodiment 2

[0151] Except that cleaning was not carried out after washing, and the total organic carbon concentration in the air was stored for 2 days in a room with a total organic carbon concentration of 8000 μgC / L, it was carried out in the same manner as in Example 1. For the prepared optical element molding raw material, it was carried out in the same manner as in Example 1. Sampling inspection of each washing and storage lot, for pure water and CH 2 I 2 The wetting angle was determined by the Owens-Wendt-Kaelble method to evaluate the surface free energy. The minimum surface free energy is 45mJ / m 2 , in addition, the minimum value of surface free energy is less than 60mJ / m 2 The bulk volume accounted for 19%. The minimum value of surface free energy is less than 60mJ / m 2 of batches, only the minimum value of the surface free energy is 60mJ / m 2 The above batches of optical element molding raw materials were continuously press-molded in the same manner as in Example 1.

[0152] ...

Embodiment 3

[0154] Same as embodiment 2, only the minimum value of surface free energy is 60mJ / m 2 The above-mentioned batches of optical element molding raw materials were formed into a film with a film thickness of 1 nm by a-C:H by thermal decomposition CVD method of acetylene gas.

[0155] The molded raw materials were stored in the same room as in Example 2 for 2 days, and the environment of the molded raw materials being transported had a total organic carbon concentration of 500 μgC / L and a cleanliness level of ISO 6. In addition, in the following CVD apparatus, the total organic carbon concentration is 2000 μgC / L, and the cleanliness level is ISO class 5.

[0156] The CVD method by thermal decomposition of acetylene gas is performed as follows.

[0157] The glass raw material was placed in a quartz shallow dish and placed in a glass bell jar (reaction vessel). After degassing the inside of the glass bell jar to below 0.5 Torr with a vacuum pump, it was heated and maintained at 48...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface free energy | aaaaa | aaaaa |

| surface | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com