Organic vertical cavity laser element with organic active region

An active area, organic technology, applied in laser components, active area structure, laser, etc., can solve the problems of low carrier mobility, driving, etc., and achieve the effects of reduced output, improved operation, and increased power conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

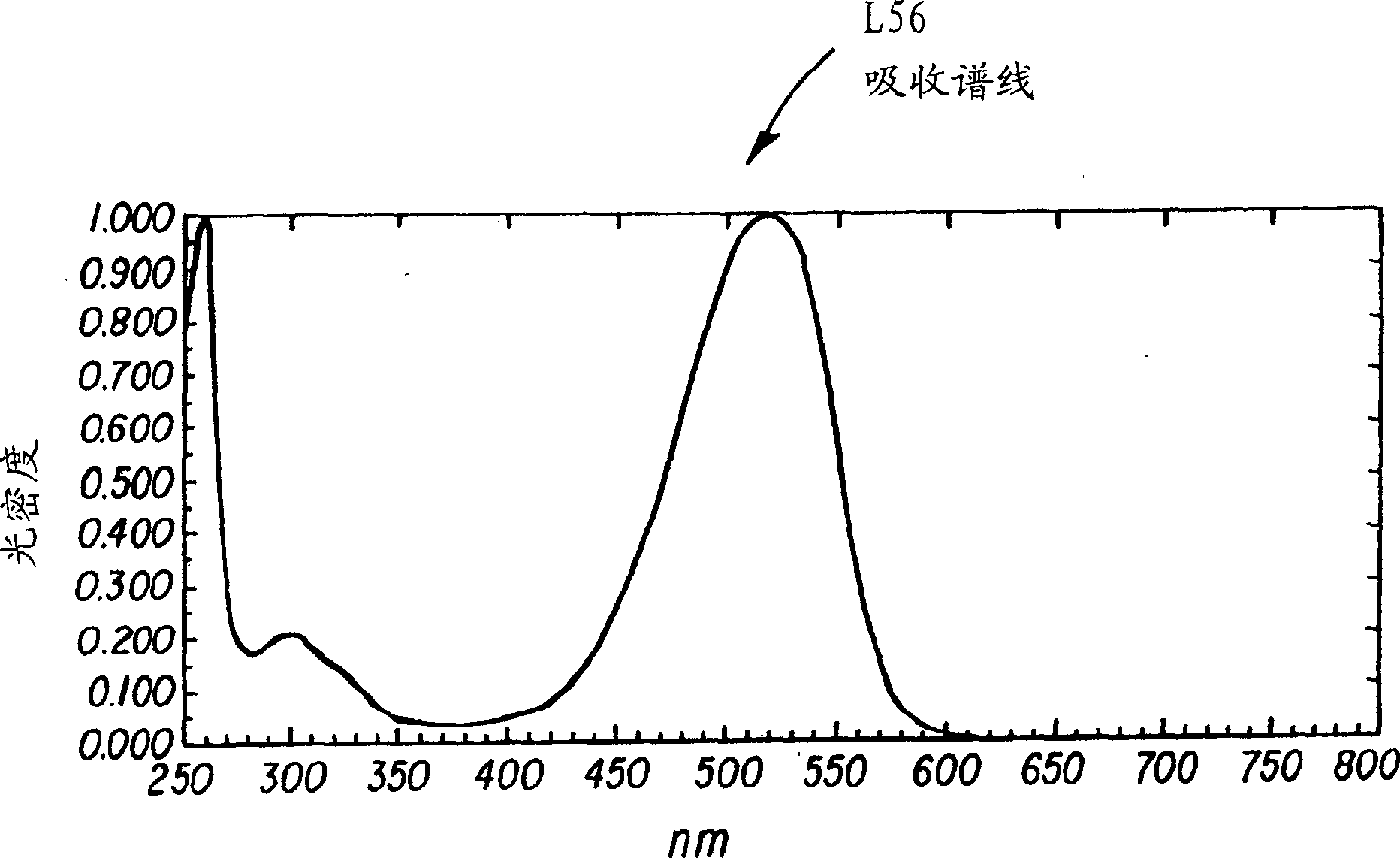

[0144] The solution ultraviolet (UV) absorption and fluorescence emission spectra of the materials identified useful dopants and host materials. Solution ultraviolet (UV) absorption spectra and fluorescence emission spectra of typical materials such as Figure 3-46 shown. All solution spectra were obtained with ethyl acetate solution except L59 (THF), L60 (water) and L62 (sucrose octaacetate).

[0145] The table lists the overlap of emission from the host material and absorption from the dopant. "X" indicates a host emission of at least 5% relative to a local maximum at a wavelength having dopant absorption of at least 5% relative to a local maximum. "0" means no (or less) overlap.

[0146] subject

[0147]Clearly, there are many combinations of host and dopant materials where the emission of the host material overlaps the absorption of the dopant material. As stated earlier, the material can be used both as a host material and as a dopant. As an example, the ...

Embodiment 2

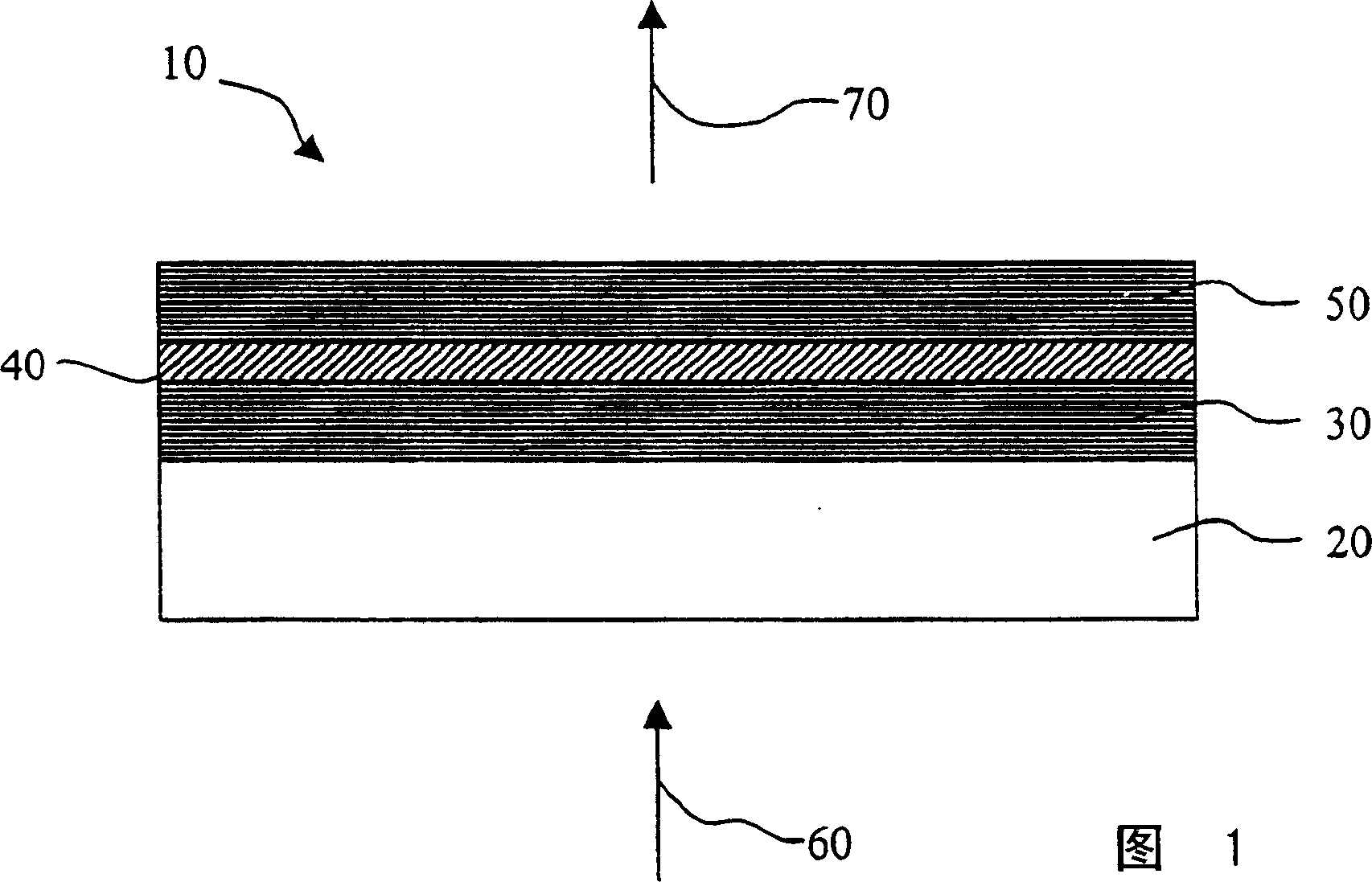

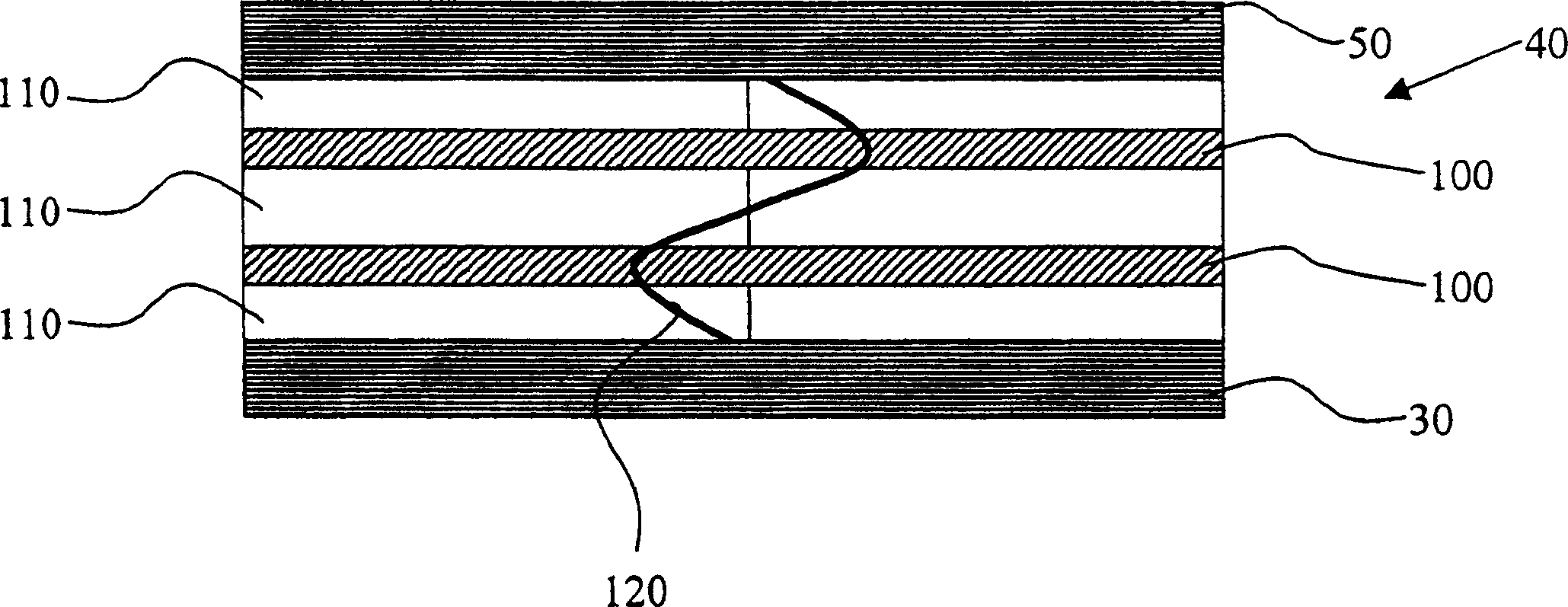

[0149] To examine the spectral and power characteristics of the device, an organic vertical cavity laser structure 10 was deposited on a 4-inch silicon substrate. By conventional electron beam deposition, a bottom dielectric stack 30 is deposited on the substrate, consisting of low and high index SiO 2 and TiO 2 Layers are alternately formed. The peak reflectance of the bottom dielectric stack at 660 nm is approximately 99.95%. The active region 40 is deposited on top of the bottom dielectric stack by high vacuum thermal evaporation. The active region is composed of 190nm TAPC, 20nm Alq plus dopant and 188nm TAPC. In one example, the dopant is L39 at a concentration of 1%; and in another case, the dopant is L62 at a concentration of 0.5%. Deposited on the active region 40 is made of SiO 2 and TiO 2 The top dielectric stack 50 is composed of alternating layers, which results in a peak reflectance measured at 660 nm of 99.85%. The top dielectric stack was deposited by ele...

Embodiment 3

[0154] Active region doping

[0155] As can be seen from the table above, the device containing the L30 dopant produced the most intense lasing peak at 5KHz. In addition, the laser intensity has minimal effect with increasing the repetition rate of the pump beam at 5 MHz. In summary, L30 is more suitable as a dopant in lasers than typical pyromethene dopants, at least by the properties of lasers mentioned above.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com