Method of manufacturing electronic part and electronic part obtained by the method

A technology of electronic components and production methods, which is applied in the direction of assembling printed circuits with electrical components, electrical components, and electrical solid devices, and can solve problems such as multi-time, narrow gaps between semiconductor chips and circuit boards, and increased costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 and comparative Embodiment 1

[0110] (1) Preparation of Adhesive Varnish 1

[0111] To 104 g of methyl ethyl ketone were added 106 g of soluble cresol resin [manufactured by SUMITOMO DUREZ Co. Ltd.; PR-HF-3; hydroxyl equivalent weight of 106], 35 g of diallyl bisphenol A type epoxy resin [NIPPON KAYAKU Co. , Ltd. manufacture; RE-810NM; epoxy equivalent is 225], and 210 g of dicyclopentadiene type epoxy resin [NIPPON KAYAKU Co, Ltd. manufacture; XD-1000L; epoxy equivalent is 248], was dissolved , to make adhesive varnish 1 for metal bonding.

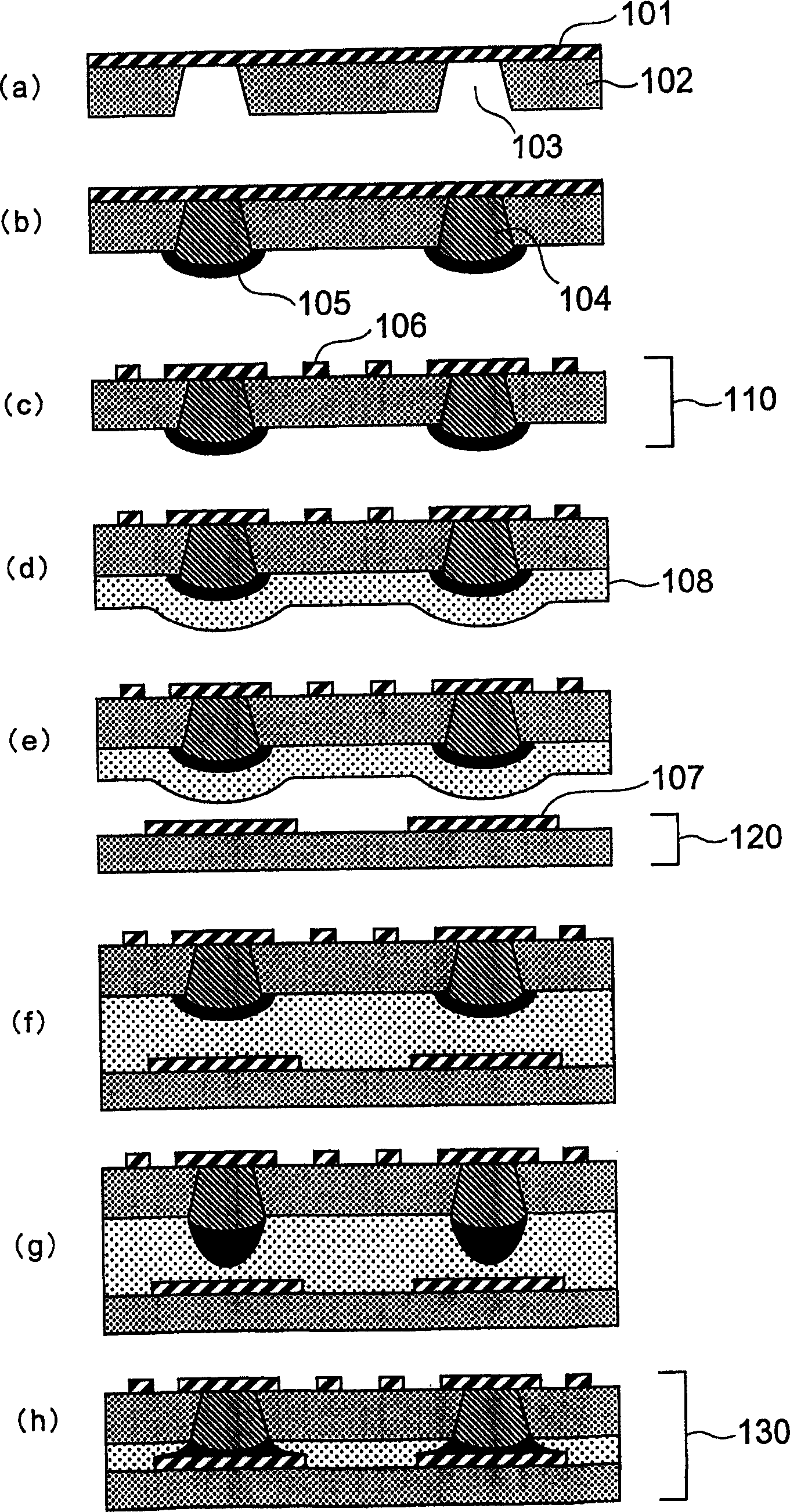

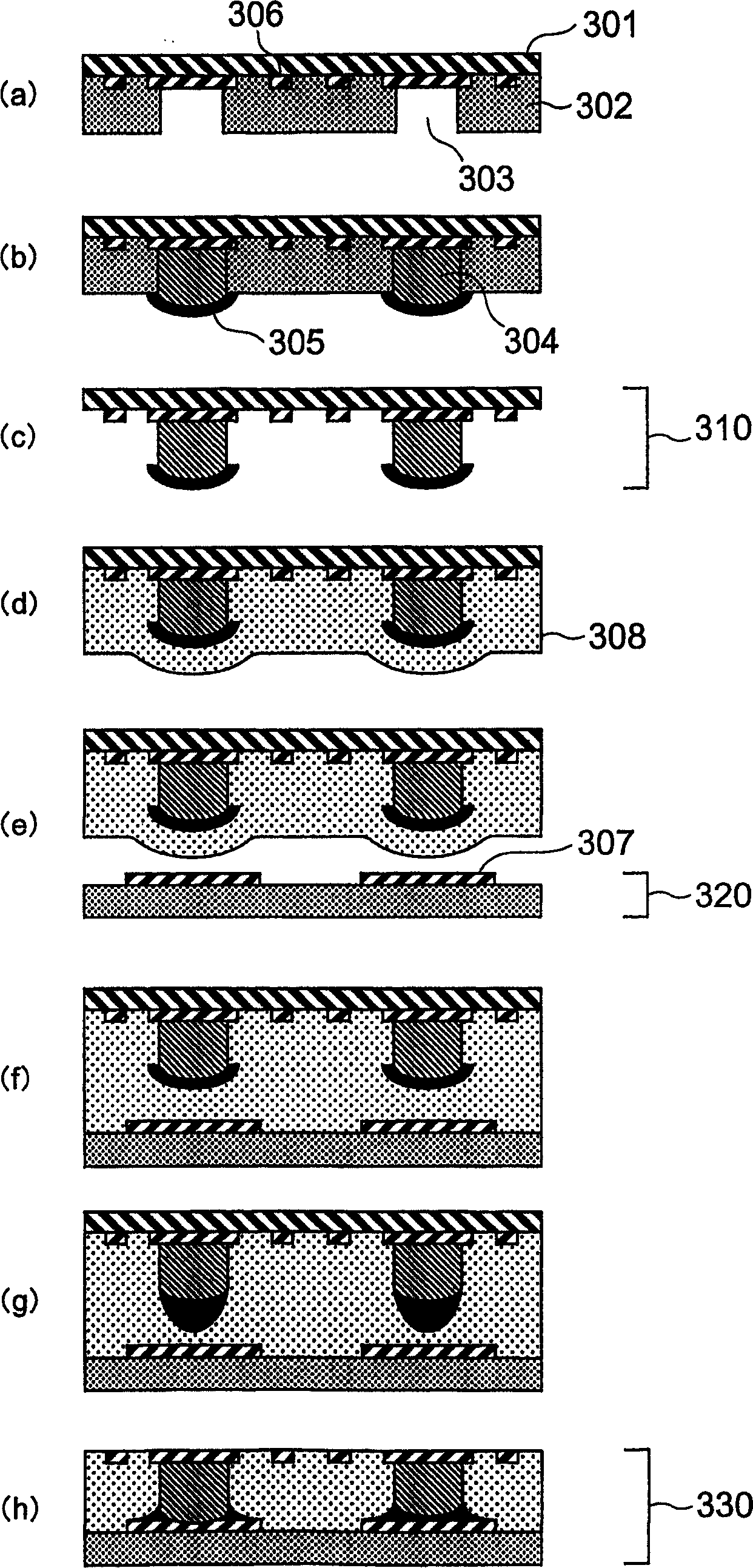

[0112] (2) Preparation of multilayer circuit board

[0113] A polyimide resin insulating film on a flexible printed wiring board (SUMITOMO BAKELITE Co., Ltd.; manufactured by A1FLEC) includes a copper foil (metal foil 101; thickness: 18 μm) and a polyimide resin insulating film (insulating film 102; thickness: 25 µm), on which 300 through holes (via holes 103) were formed, each of which was formed by UV-YAG laser, with a top diameter of 45 µm and a bottom diameter o...

Embodiment 2

[0124] (1) Preparation of Adhesive Varnish 2

[0125] 106 g of soluble cresol resin [manufactured by SUMITOMO DUREZ Co. Ltd.;, PR-HF-3], 105 g of phenolphthalein [manufactured by TOKYO KASEI Co., Ltd.], and 405 g of diallyl were added to 165 g of methyl ethyl ketone. A bisphenol A type epoxy resin [manufactured by NIPPON KAYAKU Co, Ltd.; RE-810NM] was dissolved to prepare an adhesive varnish 2 for metal bonding.

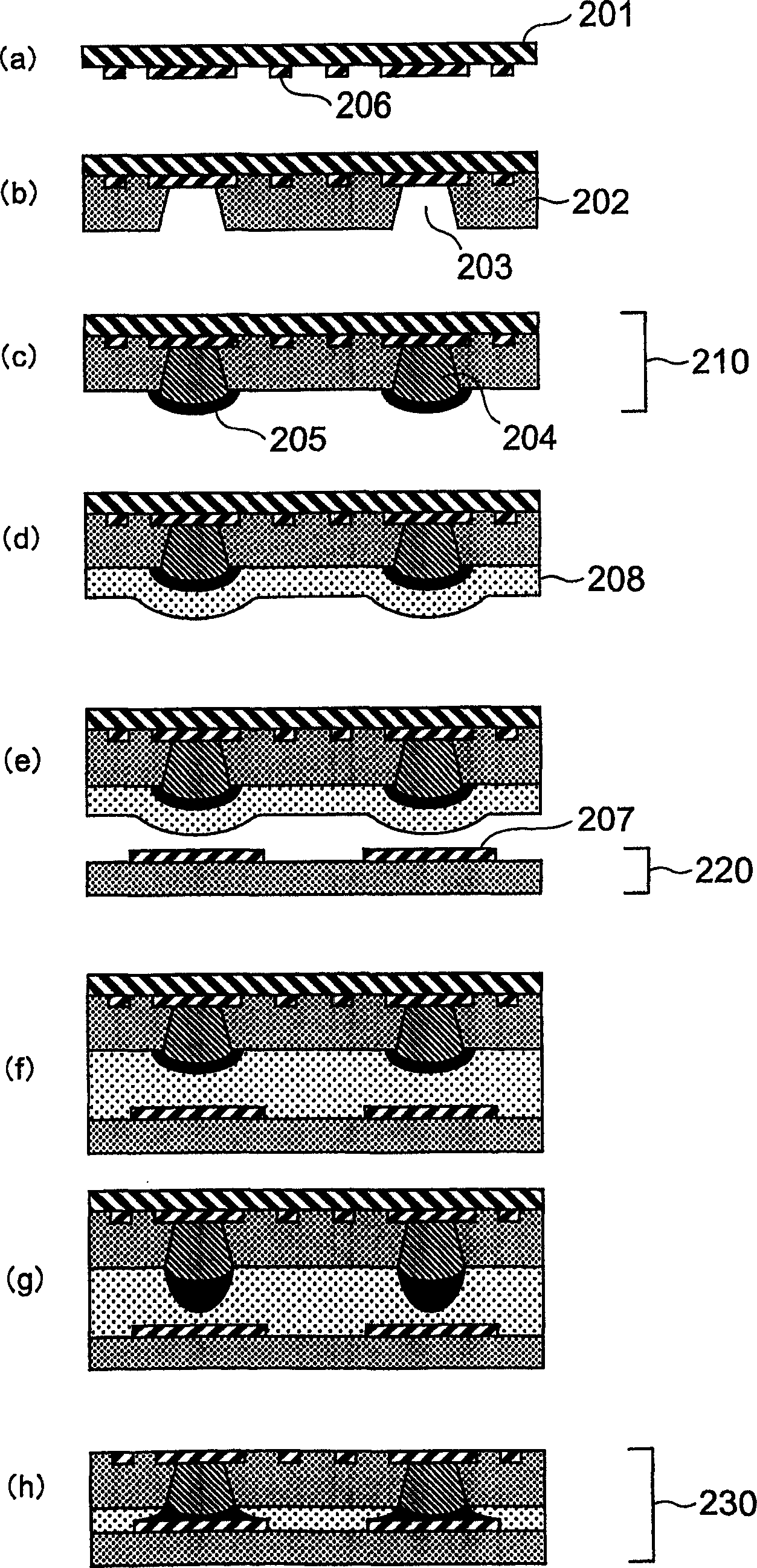

[0126] (2) Preparation of multilayer circuit board

[0127] A polyimide resin insulating film on a flexible printed wiring board (SUMITOMO BAKELITE Co., Ltd.; manufactured by A1FLEC) comprising a copper foil (metal foil 101; thickness: 18 μm) and a polyimide resin insulating film (insulating film 102; thickness: 25 µm), on which 300 through holes (via holes 103) were formed, each of which was formed by UV-YAG laser, with a top diameter of 45 µm and a bottom diameter of 25 µm. After the inner and outer parts of the hole are cleaned with a resin etching solution cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com