Laminate for electronic material

A laminated body and resin layer technology, applied to circuit substrate materials, electrical components, layered products, etc., can solve problems such as no consideration of heat resistance of lead-free solder joints, difficulty in shrinkage, and difficulty in adjusting balance

- Summary

- Abstract

- Description

- Claims

- Application Information

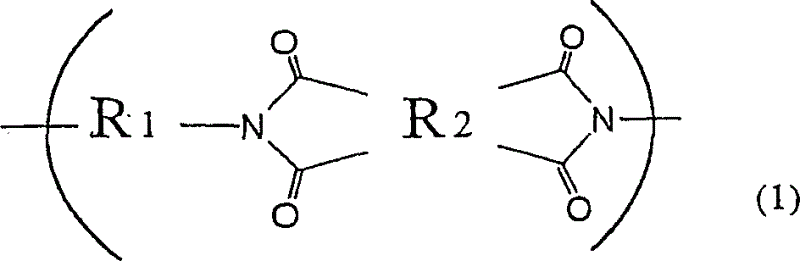

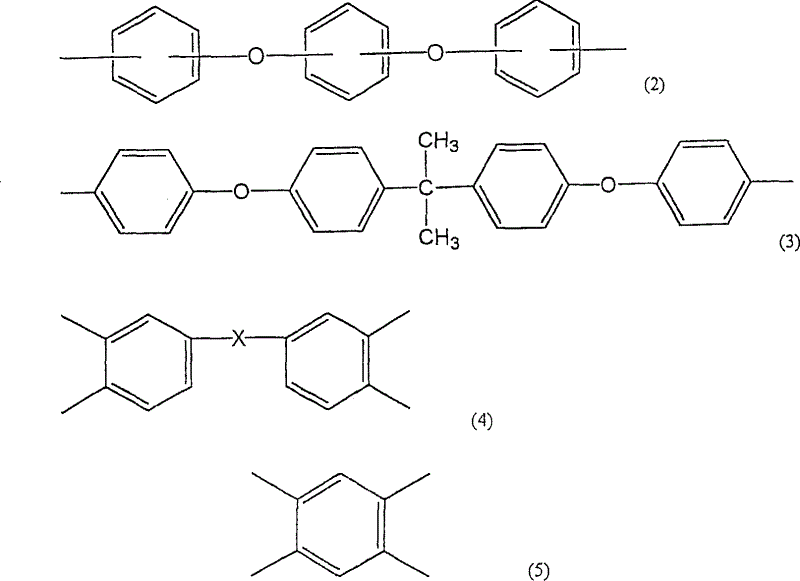

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

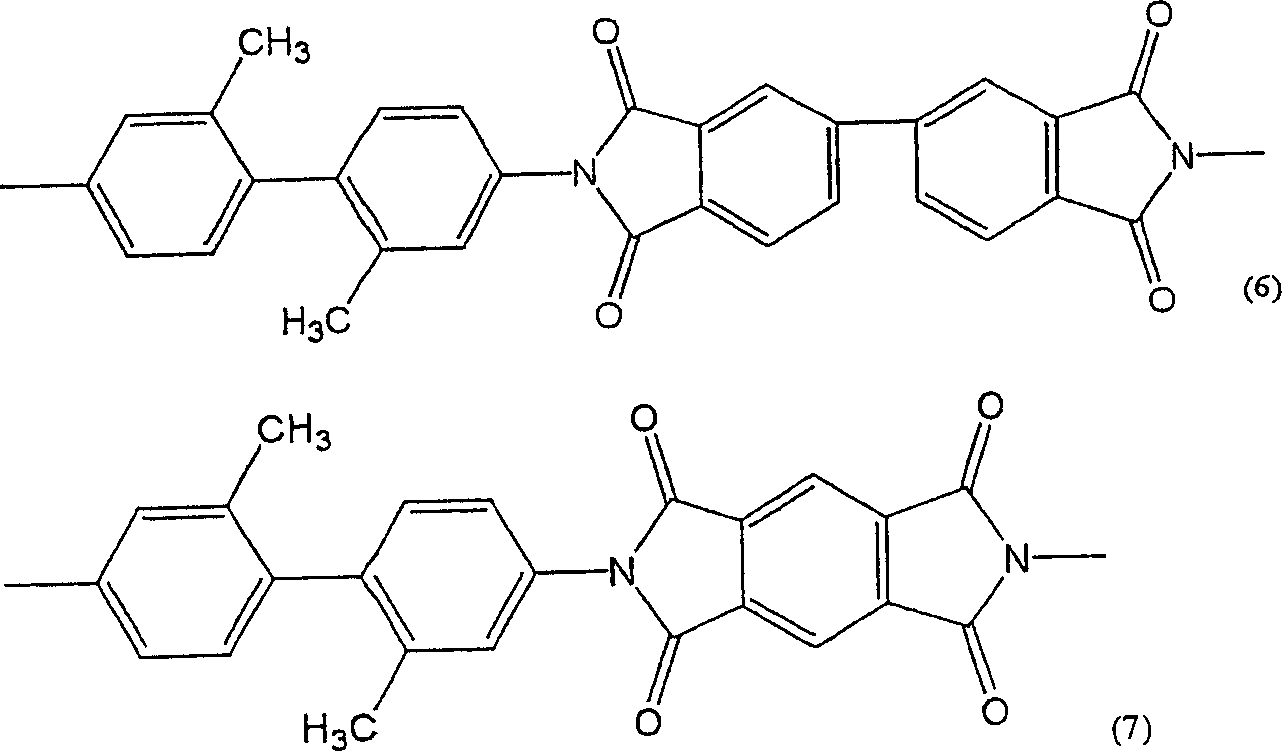

Synthetic example 1

[0082] 65.02 g (0.306 mol) of DADMB and 40.88 g (0.204 mol) of DAPE were dissolved in 1.28 kg of DMAc in a 1.3 L container while stirring. Next, 29.58 g (0.101 mol) of BPDA and 87.73 g (0.402 mol) of PMDA were added. Then, stirring was continued for about 3 hours to carry out the polymerization reaction, and a polyimide precursor resin solution a having an apparent viscosity of 150 poise (29° C.) as measured by an E-type viscometer was obtained.

Synthetic example 2

[0084] 1.3-BAB 22.13 g (0.076 mol) was dissolved in 255 g of DMAc. Next, after cooling the temperature of the solution to 5 to 10° C., 16.71 g (0.047 mol) of DSDA and 6.78 g (0.031 mol) of PMDA were added. Then continue to stir for about 1 hour to carry out the polymerization reaction, and obtain a polyimide precursor resin liquid b of 26.4 poise (25° C.).

Synthetic example 3

[0086] 29.13 g (0.071 mol) of BAPP was dissolved in 294 g of DMAc. Then 3.225 g (0.011 mol) of BPDA and 13.55 g (0.062 mol) of PMDA were added. Then continue to stir for about 3 hours to carry out the polymerization reaction to obtain a polyimide precursor resin liquid c of 35 poise (25° C.).

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com