Production of high viscosity food grade white oil

A high-viscosity, white oil technology, used in the petroleum industry, refined hydrocarbon oil, hydrocarbon distillation, etc., can solve the problems of increasing pressure, reducing space velocity, difficult to produce viscous food-grade white oil, etc., to reduce pressure, improve The effect of airspeed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] In this embodiment, naphthenic lubricating oil base oil is used as raw material, and its properties are shown in Table 1.

[0045] The catalyst used is a hydrogenation catalyst with platinum-palladium as an active component supported on a silicon oxide-alumina carrier, wherein the platinum accounts for 0.10% of the total weight of the catalyst, and the palladium accounts for 0.25% of the total weight of the catalyst. The catalyst is used in the reduced state.

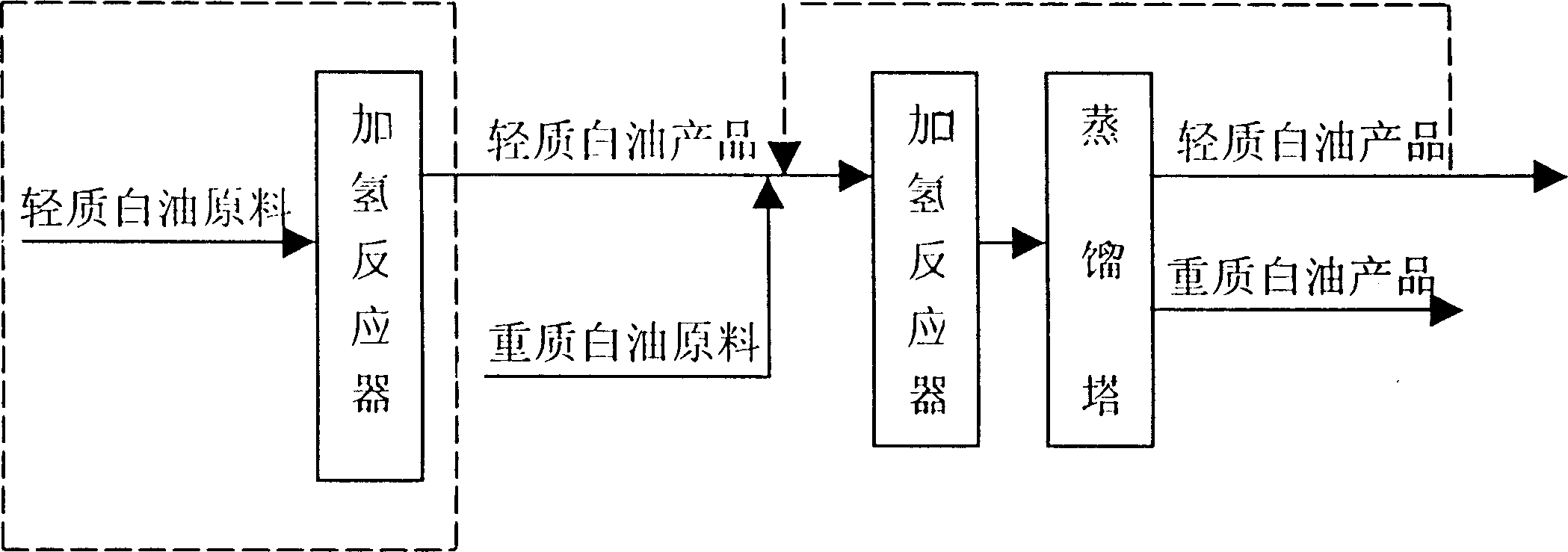

[0046] light white oil raw material

[0047] The processing process of ultra-high viscosity food-grade white oil refers to the first technological process in the accompanying drawing, and the steps are as follows:

[0048] 1. Hydrogenate the light white oil raw material to obtain light (No. 10) white oil that meets the food grade white oil standard. The hydrogenation conditions are as follows: pressure 15.0MPa, reaction temperature 230°C, volume space velocity 0.8h -1 , The volume ratio of hydrogen t...

Embodiment 2

[0058] In this example, an ultra-high viscosity naphthenic lubricating oil base oil is used as a raw material, and its properties are shown in Table 5.

[0059] The catalyst used is a hydrogenation catalyst with platinum-palladium as an active component supported on a silica-alumina carrier, wherein the platinum accounts for 0.13% of the total weight of the catalyst, and the palladium accounts for 0.30% of the total weight of the catalyst. The catalyst is used in the reduced state.

[0060] The processing process of ultra-high viscosity food-grade white oil refers to the first technological process in the accompanying drawing, and the steps are as follows:

[0061] 1. Hydrogenate the light white oil raw material to obtain light (No. 10) white oil that meets the food-grade white oil standard. The hydrogenation conditions are as follows: pressure 15.0MPa, reaction temperature 240°C, volume space velocity 0.8h -1 , The volume ratio of hydrogen to oil is 500:1. The properties of...

Embodiment 3

[0072] In this embodiment, the same naphthenic lubricating oil base oil as in Embodiment 1 is used as raw material.

[0073] The catalyst used is a hydrogenation catalyst with platinum-palladium as an active component supported on a silica-alumina carrier, wherein the platinum accounts for 0.22% of the total weight of the catalyst, and the palladium accounts for 0.26% of the total weight of the catalyst. The catalyst is used in the reduced state.

[0074] The processing process of ultra-high viscosity food-grade white oil refers to the first technological process in the accompanying drawing, and the steps are as follows:

[0075] 1. Hydrogenate the light white oil raw material to obtain light (No. 10) white oil that meets the food-grade white oil standard. The hydrogenation conditions are as follows: pressure 15.0MPa, reaction temperature 240°C, volume space velocity 0.8h -1, The volume ratio of hydrogen to oil is 500:1. The properties of the light white oil product after hy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com