Method for preparing low dielectric films

A technology of low dielectric constant and hydrogenated silicon, which is applied in the direction of circuits, electrical components, electrical solid devices, etc., can solve the problem of high dielectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

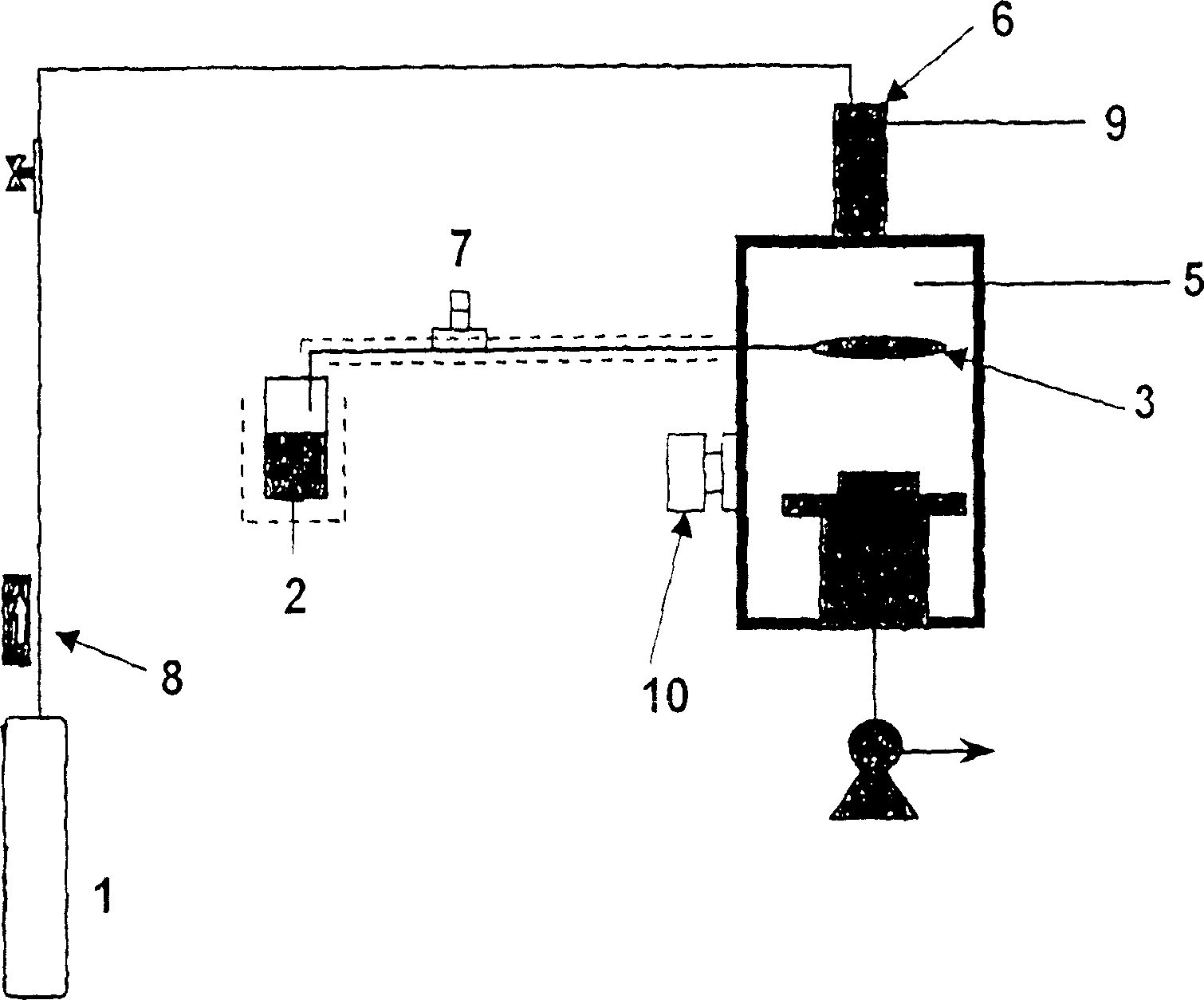

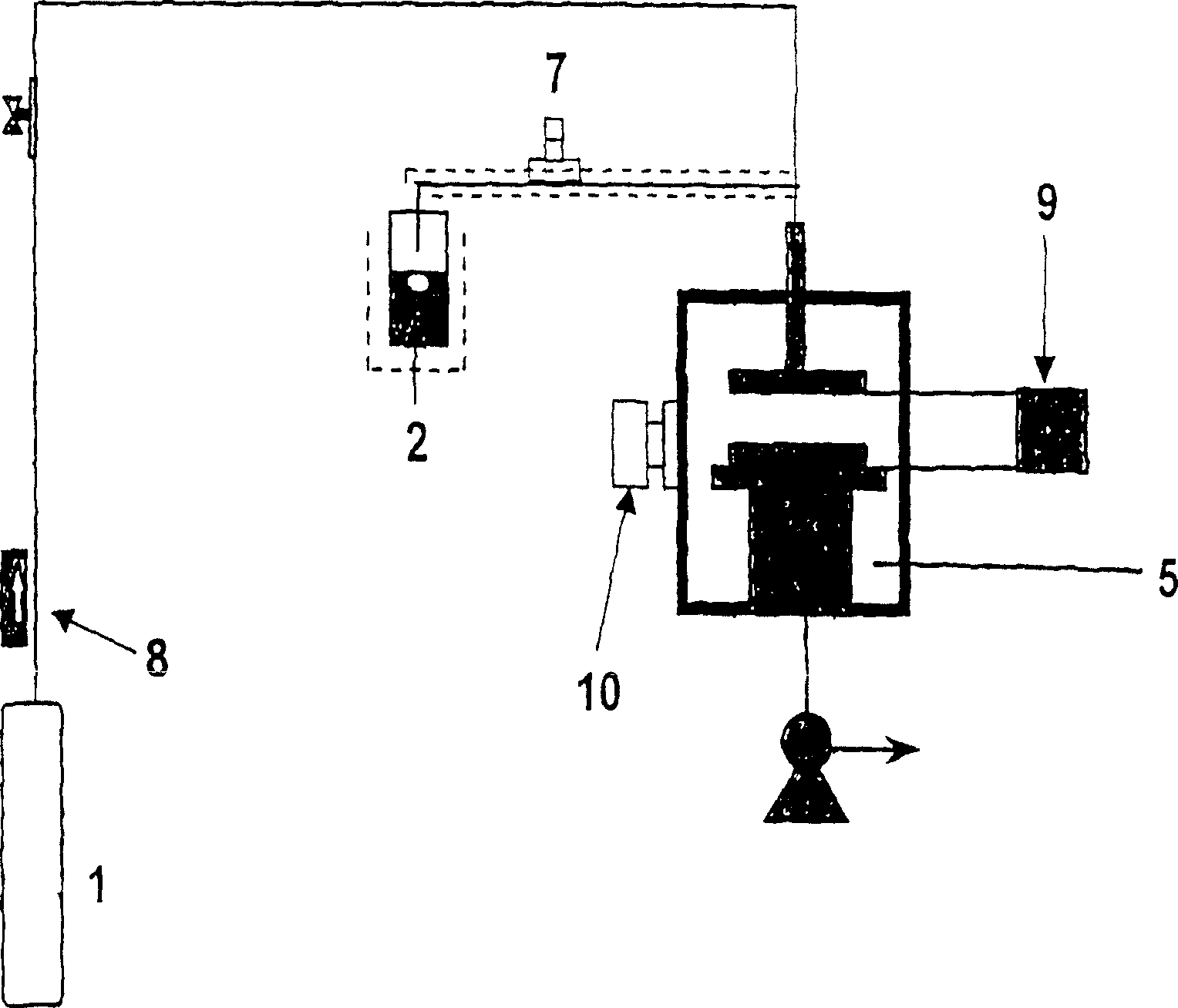

[0047] exist Figure 1b In the direct plasma device shown, vinyltrimethylsilane (VTMS, SiC 5 h 12 ) and O 2 SiCOH films were deposited on Pt substrates. During film deposition, O 2 The flow ratio of / VTMS was varied in the range of 1 to 13.3. The pressure and temperature in the reactor were 1 mmHg and 30°C, respectively, and the applied plasma power was 60W. The film thus deposited is annealed at a temperature of 300 to 500° C. under an argon atmosphere to obtain a film with a low dielectric constant.

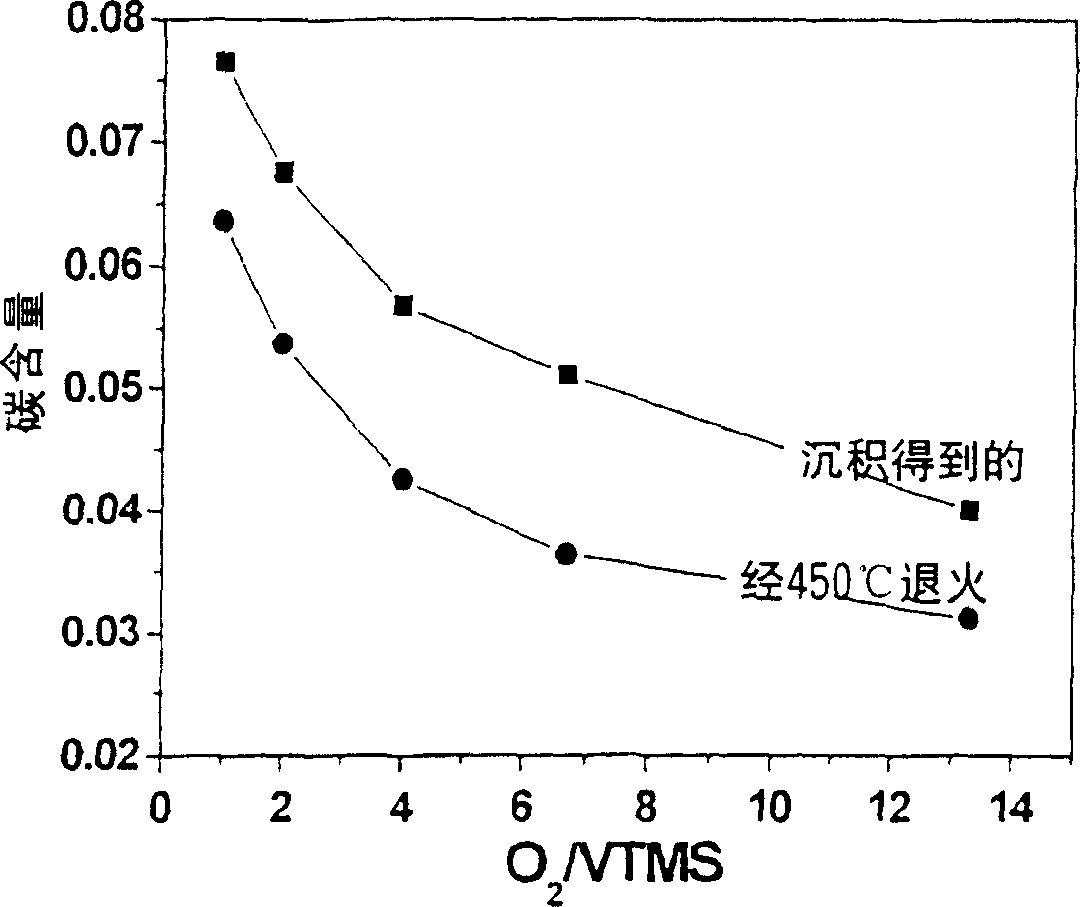

[0048] Such as figure 2 As shown, the corresponding carbon content of the as-deposited film and the film annealed at 450 °C increased with O 2 / VTMS flow ratio increases and decreases. image 3 The films annealed at 450° C. were shown to have a dielectric constant of 1.8 to 2.4, while the film deposited without annealing had a dielectric constant of 2.3 to 2.8. Figure 4 and 5 displayed on O 2 When the / VTMS flow ratio is 2, the dielectric constant of the film obtai...

Embodiment 2

[0052] Repeat the step of embodiment 1, difference is to use tetramethylsilane (4MS, SiC 4 h 12 ) and C 2 f 4 A mixture of VTMS (1:1) was used instead of VTMS to obtain a deposited film, which was subsequently annealed.

[0053] Figure 6 and Figure 7 The carbon content and dielectric constant of the as-deposited and annealed films are shown, respectively. The dielectric constant of the deposited film was 3.0 or lower, and the dielectric constant of the film annealed at 450°C was 2.5 or lower. Figure 8 and Figure 9 are displayed in O 2 / (4MS+C 2 f 4 ) flow ratio is 4, the effect of annealing temperature (annealing time = 0.5 hours) and annealing time (annealing temperature = 400 ° C) on the dielectric constant of the film. Films annealed at 300 to 500° C. for 0.5 hours had a dielectric constant of 2.75 or less.

Embodiment 3

[0055] Repeat the steps of Example 1, using tetravinyltetramethylcyclotetrasiloxane (TVTMCTSO, Si 4 o 4 Cl 2 h 24 ) instead of VTMS to obtain a deposited film, which is subsequently annealed.

[0056] Figure 10 and Figure 11 The carbon content and dielectric constant of the as-deposited and annealed films are shown, respectively. The dielectric constant of the deposited film was 2.4 or lower, and the dielectric constant of the film annealed at 450°C was 2.2 or lower. Figure 12 and Figure 13 are displayed in O 2 The effect of annealing temperature (annealing time = 0.5 hours) and annealing time (annealing temperature = 450°C) on the dielectric constant of the film when the / TVTMCTSO flow ratio is 4. Films annealed at 300 to 500° C. for 0.5 hours had a dielectric constant of 2.1 or less.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com