Method for reclaiming calcium oxalate from sewage comprising oxalic acid

A technology for calcium oxalate and acidic wastewater, applied in the field of calcium oxalate recovery, can solve problems such as lead pollution, and achieve the effects of avoiding pollution, stabilizing chemical properties, and improving recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

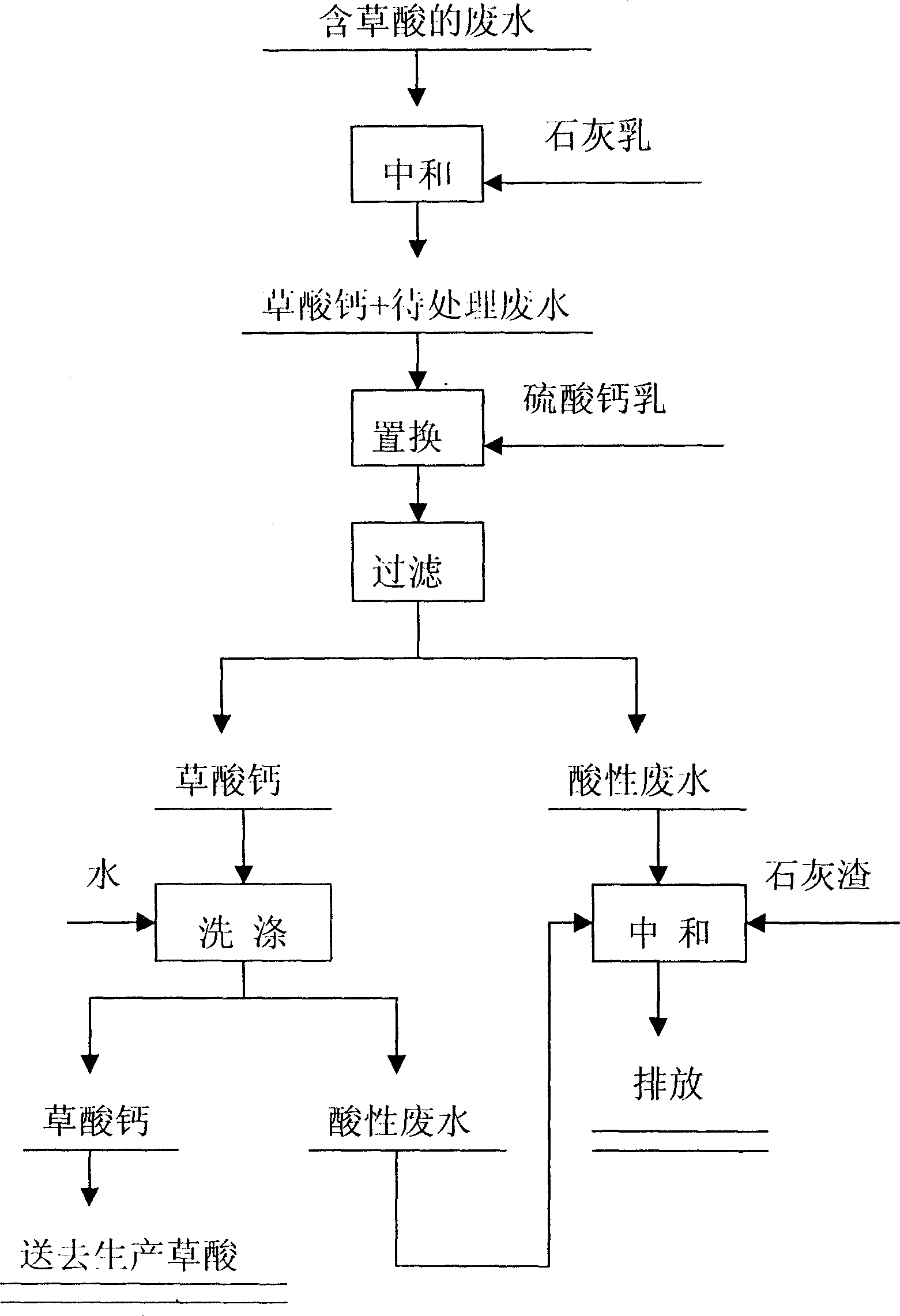

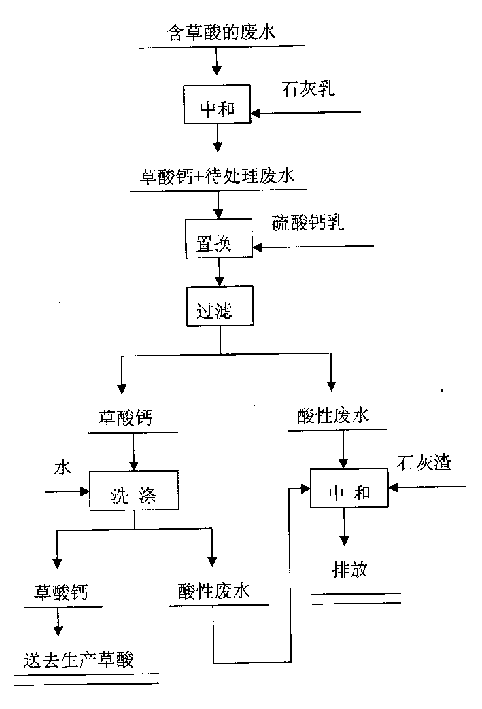

Image

Examples

Embodiment 1

[0011] First, put 5.1 cubic meters of waste water containing 209 g / L oxalic acid into a jacketed enamel reaction kettle, start stirring, then add lime milk to carry out neutralization reaction, control the reaction temperature at 80°C, and reach the oxalate content in the waste water When it is 22g / L, stop adding milk of lime, obtain part of calcium oxalate and wastewater to be treated, the main neutralization reaction is:

[0012]

[0013] According to the oxalate content in the waste water to be treated is 22g / L, then add calcium sulfate 346.8kg (according to CaSO 4 Dry weight 2 times of stoichiometric amount) emulsion, control reaction temperature is 95 ℃, obtain calcium oxalate and acid waste water, main displacement reaction is:

[0014]

[0015]

[0016]

[0017] Dry the reacted material through a centrifuge, and wash it twice with water at the same time, and the calcium oxalate after drying can reach the following indicators through analysis:...

Embodiment 2

[0025] 4.8 cubic meters of waste water containing oxalic acid, add milk of lime for neutralization reaction, control the reaction temperature at 85°C, until the content of oxalate in the waste water is 25g / L, then add calcium sulfate 371kg (CaSO 4 According to the emulsion of 2 times of the stoichiometric amount) of the dry weight, the temperature of the replacement reaction is controlled to be 95° C., and all the other are the same as in Example 1.

Embodiment 3

[0027] Control the neutralization reaction temperature to be 90°C, add calcium sulfate 400kg (according to CaSO 4 Dry weight more than 2 times of the emulsion of the stoichiometric amount), the control displacement reaction temperature is 98 ℃, and all the other are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com