Shaping ring light-beam differiential confocal sensor with high space resolution capability

A technology with high spatial resolution and ring beam, which is applied in the direction of instruments, optical devices, and measuring devices, can solve the problems of three-dimensional fine structure micro-steps, micro-grooves, integrated circuit line width, and surface topography that cannot be accurately resolved. Achieve the effect of improving lateral resolution, improving signal-to-noise ratio, and reducing energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

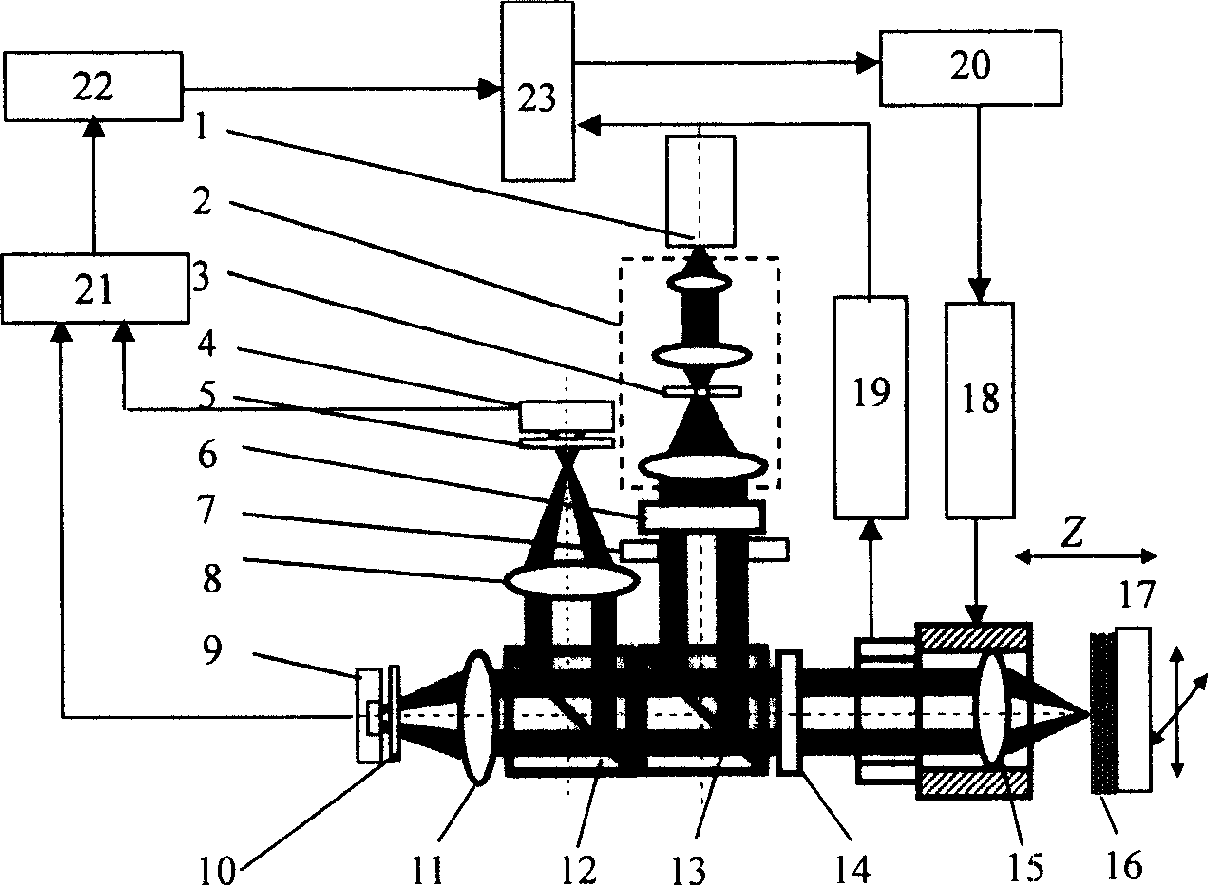

[0028] The structure and working principle of the high spatial resolution shaping annular beam differential confocal sensor of the present invention will be described in detail below in conjunction with the embodiments and accompanying drawings:

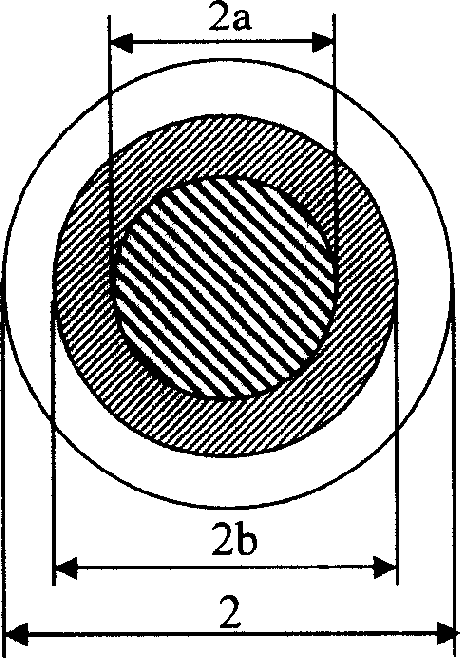

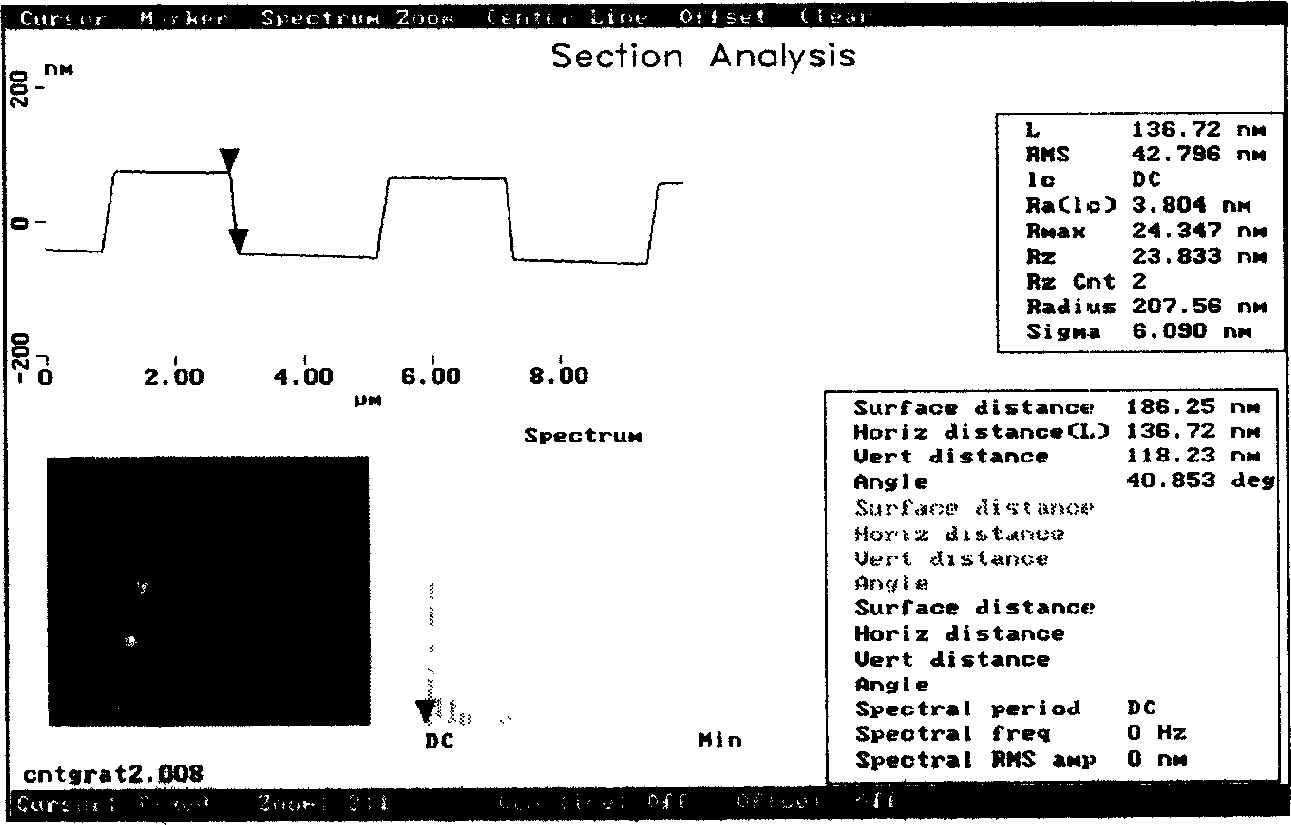

[0029] The structure of the high spatial resolution shaping annular beam differential confocal sensor in this embodiment is as follows figure 2 As shown, it includes: a laser 1, a beam expander 2 sequentially placed at the emitting end of the laser, a spatial filtering pinhole 3, a binary optical device 6 with circular phase distribution, and an adjustable diaphragm for adjusting the normalized radius of the incident ring light 7. Polarization beam splitter 13, a quarter wave plate 14 placed on the transmission light path of the polarization beam splitter, microscopic objective lens Z direction displacement tracking sensor 19, microscopic objective lens 15, microscopic objective lens Z direction micro displacement drive system 18, P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com