Method for producing protein chip

A protein chip and manufacturing method technology, applied in the field of biosensing, can solve the problem of low integration and achieve the effect of ensuring activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

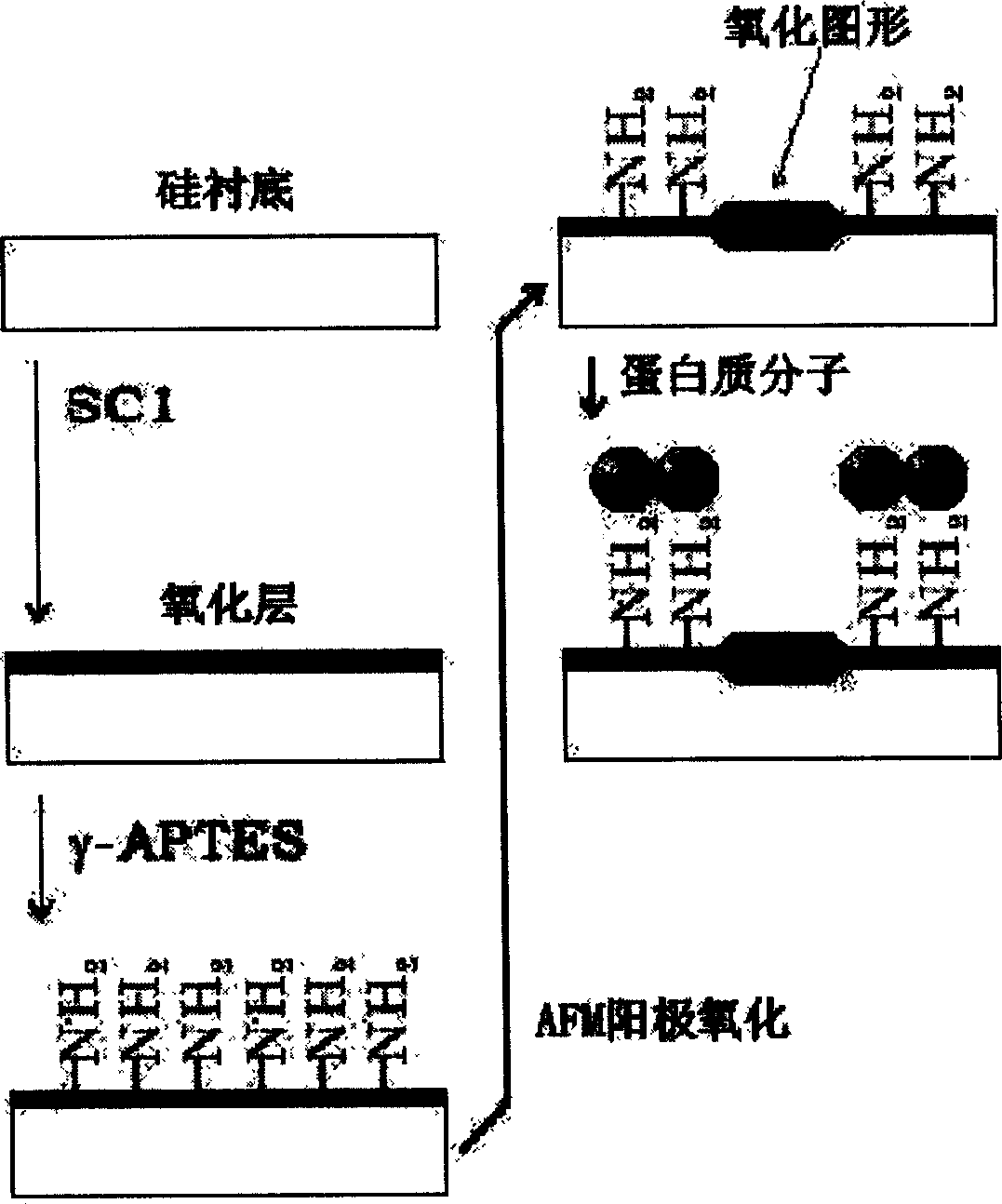

[0016] Embodiment 1: the concrete processing steps of the present invention are as follows:

[0017] a. First, standard semiconductor technology is used to clean and thermally oxidize the silicon wafer; the surface of the cleaned and thermally oxidized silicon wafer has a layer of 500 nanometer silicon dioxide layer;

[0018] b. immerse the above-mentioned pretreated silicon wafer in γ-amino-propyl-triethylsilane (γ-APTES) for 10 minutes, so that the surface of the silicon wafer has amino groups and has affinity for protein molecules;

[0019] c. Adopt atomic force microscope (AFM) nano-etching technology to etch nano-patterns on the above-mentioned processed silicon wafer surface; the etching method is: apply a voltage between the atomic force microscope probe and the silicon surface, so that Atoms are oxidized into silicon dioxide; the probe is moved and etched into a square array with a side length of 200 nanometers and a line width of 50 nanometers. The amino group on the ...

Embodiment 2

[0021] Embodiment two: the concrete processing steps of the present invention are as follows:

[0022] a. First, standard semiconductor technology is used to clean and thermally oxidize the silicon wafer; there is a silicon dioxide layer of 800 nanometers on the surface of the cleaned and thermally oxidized silicon wafer;

[0023] b. immerse the above-mentioned pretreated silicon wafer in γ-amino-propyl-triethylsilane (γ-APTES) for 10 minutes, so that the surface of the silicon wafer has amino groups and has affinity for protein molecules;

[0024] c. Adopt atomic force microscope (AFM) nano-etching technology to etch nano-patterns on the above-mentioned processed silicon wafer surface; the etching method is: apply a voltage between the atomic force microscope probe and the silicon surface, so that Atoms are oxidized into silicon dioxide; move the probe, etch concentric circles with a radius of 200 nanometers and 400 nanometers and a line width of 50 nanometers. The 100 nm an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com