Absorbing products

An absorbent and product technology, applied in the field of absorbent products, can solve the problems of reduced moisture permeability and difficulty, and achieve the effects of increased added value, high moisture permeability, and prevention of stuffiness and rashes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

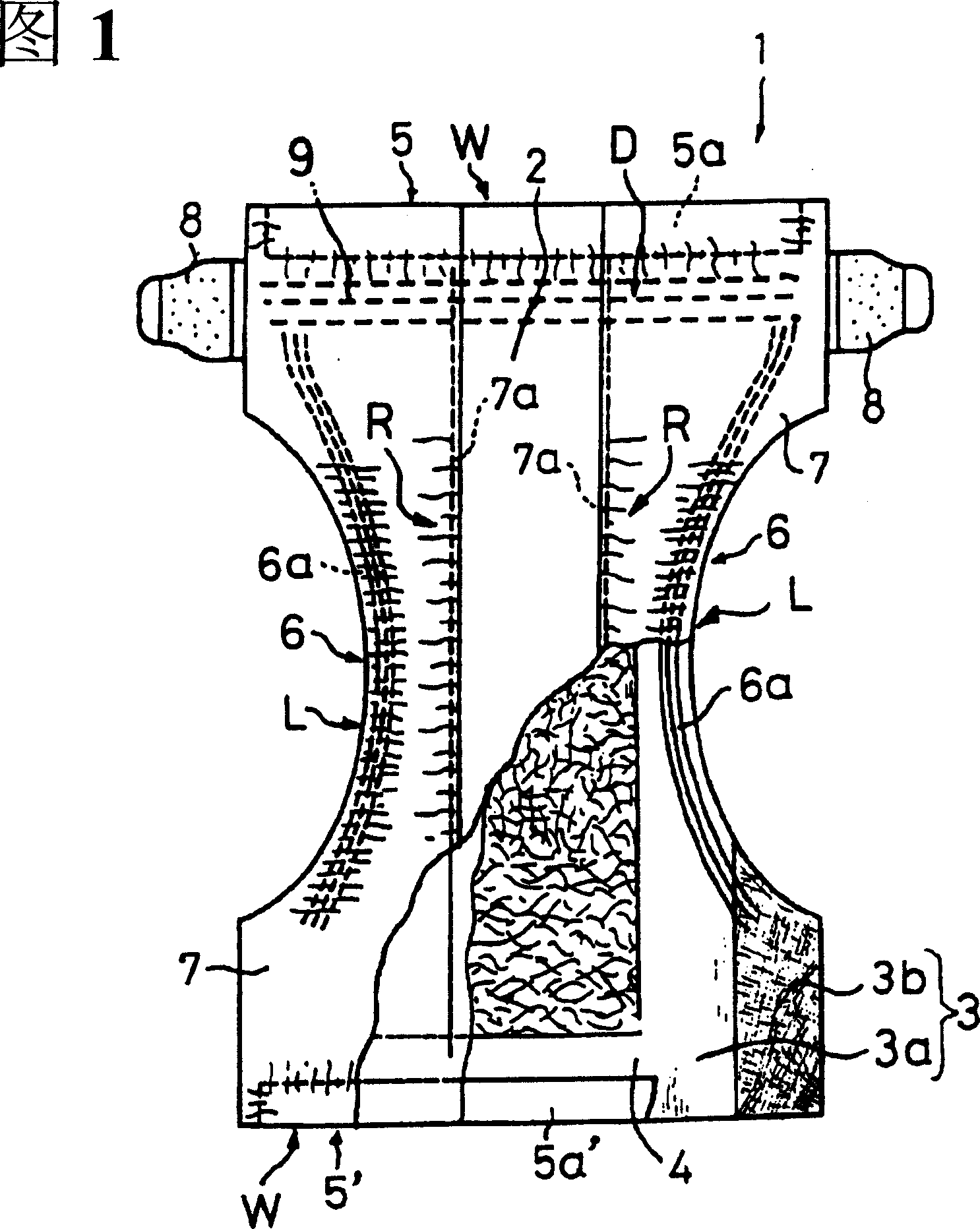

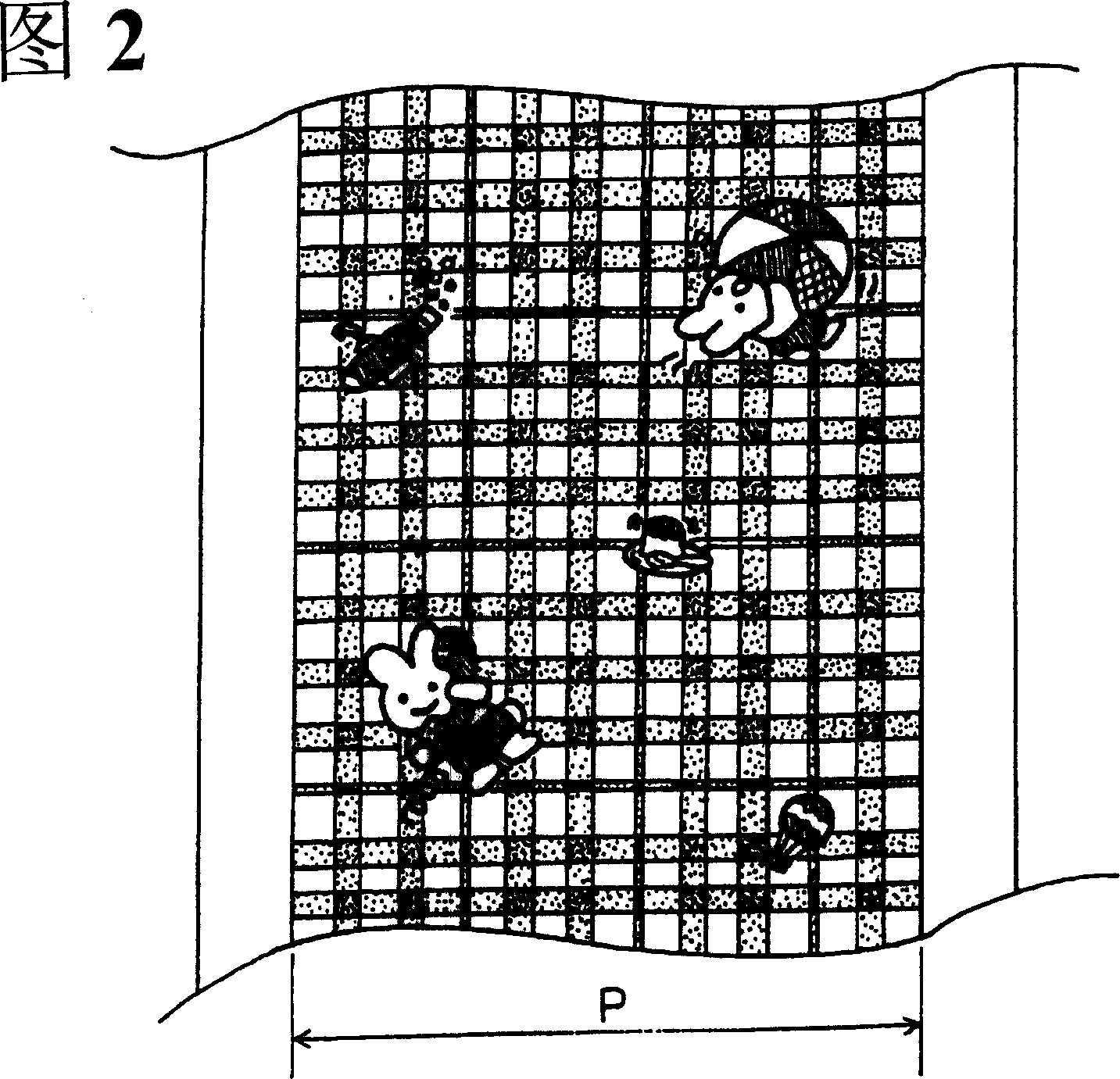

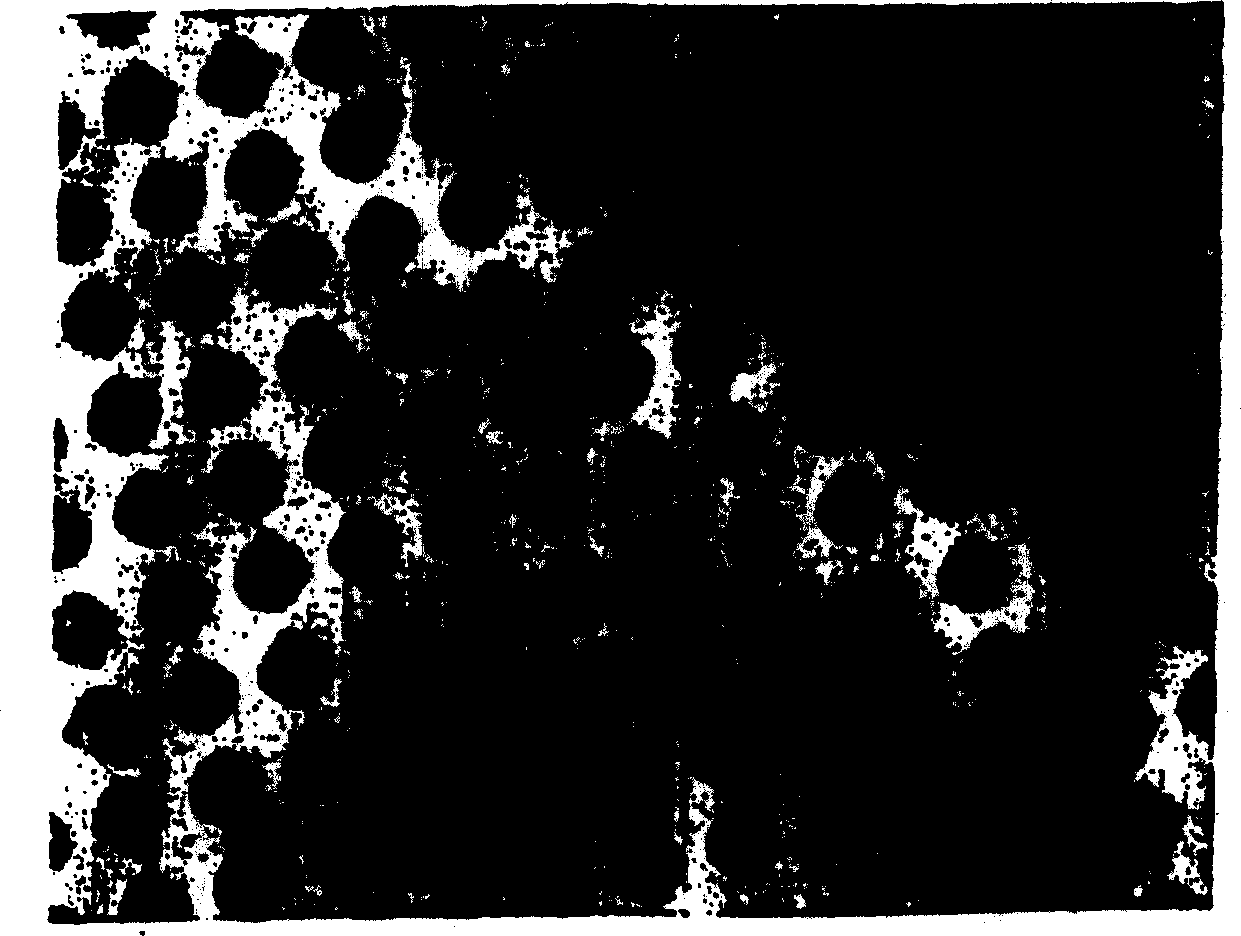

Embodiment 1

[0039] A polyethylene stretched microporous film containing calcium carbonate particles was used as the moisture-permeable film. The quantitative (weight per unit area) of the film is 20g / m 2 , moisture permeability is 2.2g / (100cm 2 h). This film is used in Kao Corporation's disposable diapers for babies "Merry-Zure" belt fastening type. When the surface of the thin film was observed with an electron microscope, the average diameter of pores on the surface was 0.6 μm (magnification: 1000 times). Use a six-color offset printing machine or use offset color inks containing organic pigments of various colors and polyurethane resins as inks to print the pattern shown in Figure 2 on one side of the film. The details of the printing are shown in Table 1. Quantitative 15g / m with hot melt adhesive 2 The non-woven fabric is laminated to the printing part. The water vapor transmission rate of the negative sheet obtained is 2.1g / (100cm 2 h). Using the thus obtained backsheet and u...

Embodiment 2~10

[0057] Using an offset printing machine, use the printing ink of cyan organic pigment system under the conditions shown in Table 2, on the same film as the moisture-permeable film used in Example 1 (but the moisture permeability is 2.0g / (100cm 2 • h)) for printing. The pattern is done using other rabbit patterns obtained by halftone dot printing. For the obtained backsheet, various area ratios and water vapor transmission rates were measured. Moreover, while measuring the color difference of a pattern by the following method, the appearance of a pattern was evaluated by the said method. The results are shown in Table 2.

Embodiment 11

[0059] Use the same film as the moisture-permeable film used in Example 1 (but the moisture permeability is 2.3g / (100cm 2 • h)), monochrome printing over the entire surface. The ink is the same kind of green organic pigment ink mainly containing polyurethane resin as in Example 1, and the ratio of the resin component in the ink coating film is about 45%. Others carry out identically with embodiment 2. For the obtained backsheet, various area ratios and water vapor transmission rates were measured. Moreover, while measuring the color difference of a pattern by the following method, the appearance of a pattern was evaluated by the said method. The results are shown in Table 2. Even if printing is performed on the entire surface, the resin component of the ink is reduced compared with Example 1, and a product having a high water vapor transmission rate can be obtained on the back sheet at a ratio of a substantial area ratio.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com