Dyeing method for polypropylene fibre or fabric

A polypropylene fiber and dyeing method technology, applied in the textile field, can solve the problems of inability to perform fine denier spinning, low color fixation rate, and poor deep dyeability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

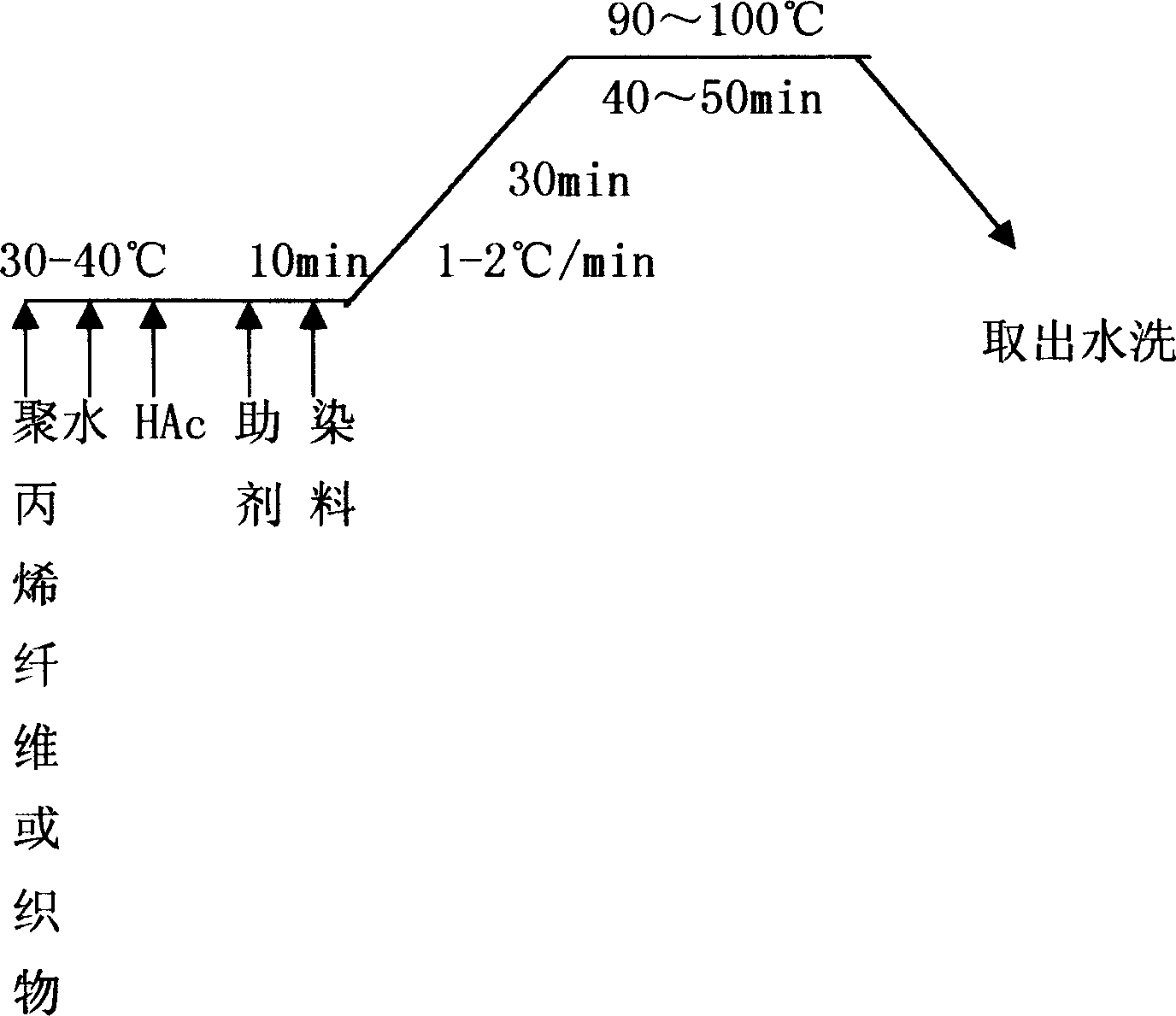

[0017] Embodiment 1: The polypropylene fabric is put into the low-temperature plasma treatment equipment reaction chamber to carry out low-temperature plasma treatment, the treatment conditions are: power 60W, time 120s, vacuum degree 0.5torr, treatment atmosphere selects air, then the fabric after treatment Soak in an acrylic acid solution with a concentration of 20wt% for 3 hours. Dyeing with disperse dyes, the initial dyeing temperature is 30°C, and the temperature is gradually raised at a rate of 2°C / min until the dye solution boils, and the dyeing is continued for 40-50 minutes, then taken out and washed with water. The dyeing rate reaches 80-90%, and the color fastness reaches 4-5 grades.

Embodiment 2

[0018] Embodiment 2: The polypropylene fabric is put into the low-temperature plasma treatment equipment reaction chamber to carry out low-temperature plasma treatment, the treatment conditions are: power 100W, time 90s, vacuum degree 0.7torr, treatment atmosphere selects air, then the fabric after treatment Soak in an acrylic acid solution with a concentration of 15wt% for 2 hours. Dyeing with disperse dyes, the initial dyeing temperature is 30°C, and the temperature is gradually raised at a rate of 2°C / min until the dye solution boils, and the dyeing is continued for 40-50 minutes, then taken out and washed with water. The dyeing rate reaches 80-90%, and the color fastness reaches 4-5 grades.

Embodiment 3

[0019] Embodiment 3: the polypropylene fabric is put into the low-temperature plasma treatment equipment reaction chamber to carry out low-temperature plasma treatment, the treatment conditions are: power 100W, time 100s, vacuum degree 0.3torr, treatment atmosphere selects argon gas, then the processed The fabric was soaked in 15wt% acrylic acid solution for 4h. Dyeing with disperse dyes, the initial dyeing temperature is 35°C, and the temperature is gradually raised at a rate of 2°C / min until the dye solution boils, and the dyeing is continued for 40-50 minutes, then taken out and washed with water. The dyeing rate reaches 80-90%, and the color fastness reaches 4-5 grades.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com